Flat Rolling

The Model T10727 Slip Roll can be used to flat roll sheet metal up to 20 gauge mild steel. This is done to flatten or slightly reduce the thickness of workpieces.

When you raise and lower the upper roller with the thickness adjustment knobs, it is important to keep the upper and lower rollers parallel by adjusting the knobs in even amounts. This keeps the space and pressure even along the length of the rollers.

Pinching/Crushing

Hazard

To reduce the risk of inju- ry, keep hands, fingers, or other body parts away from the rollers during opera- tion.

To flat roll a workpiece:

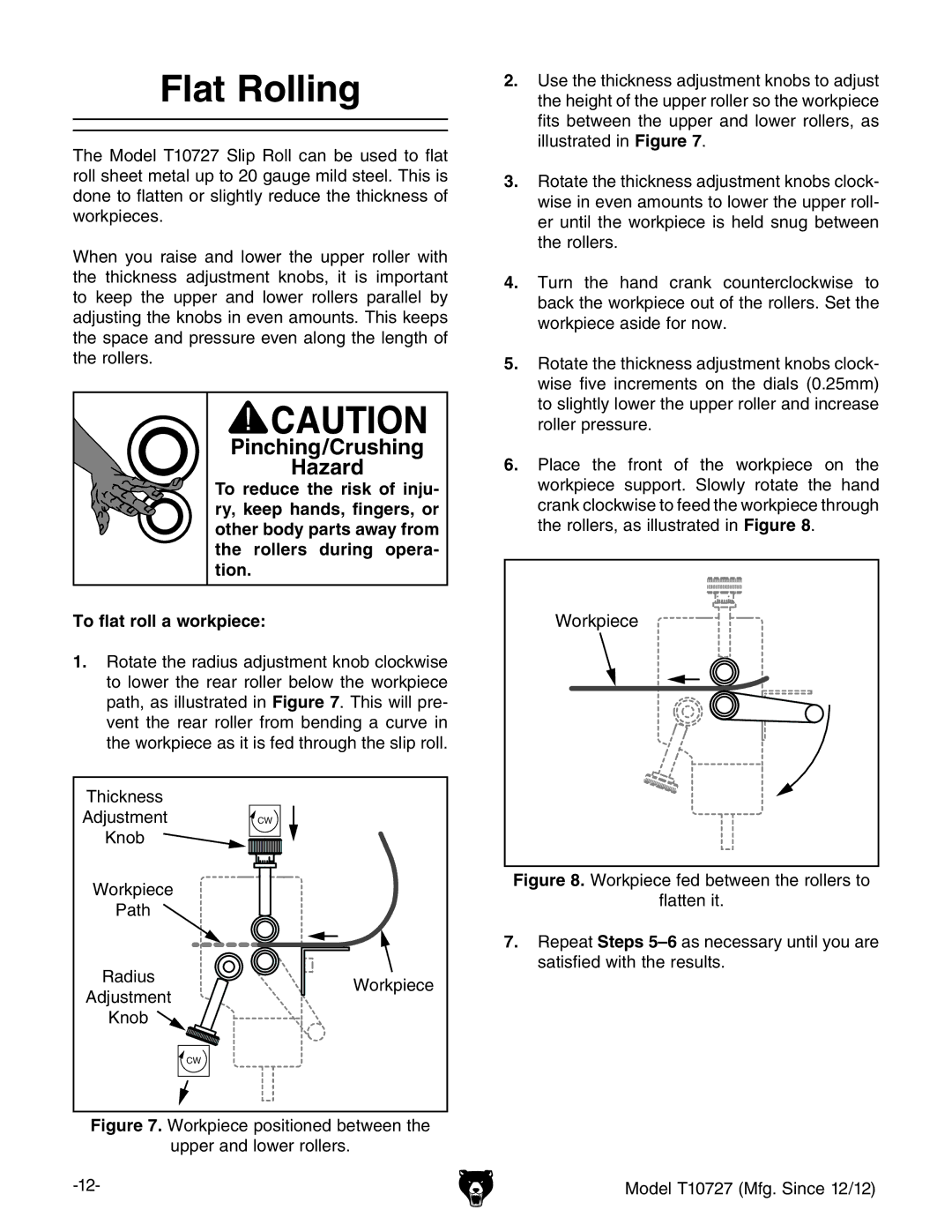

1.rotate the radius adjustment knob clockwise to lower the rear roller below the workpiece path, as illustrated in Figure 7. This will pre- vent the rear roller from bending a curve in the workpiece as it is fed through the slip roll.

2.Use the thickness adjustment knobs to adjust the height of the upper roller so the workpiece fits between the upper and lower rollers, as illustrated in Figure 7.

3.rotate the thickness adjustment knobs clock- wise in even amounts to lower the upper roll- er until the workpiece is held snug between the rollers.

4.turn the hand crank counterclockwise to back the workpiece out of the rollers. Set the workpiece aside for now.

5.rotate the thickness adjustment knobs clock- wise five increments on the dials (0.25mm) to slightly lower the upper roller and increase roller pressure.

6.place the front of the workpiece on the workpiece support. Slowly rotate the hand crank clockwise to feed the workpiece through the rollers, as illustrated in Figure 8.

Workpiece

Thickness

Adjustment

Knob

Workpiece

Path

Radius

Adjustment

Knob ![]()

CW

Workpiece

Figure 8. Workpiece fed between the rollers to

flatten it.

7.repeat Steps 5–6 as necessary until you are satisfied with the results.

CW