|

| Basic Troubleshooting | |

|

|

| |

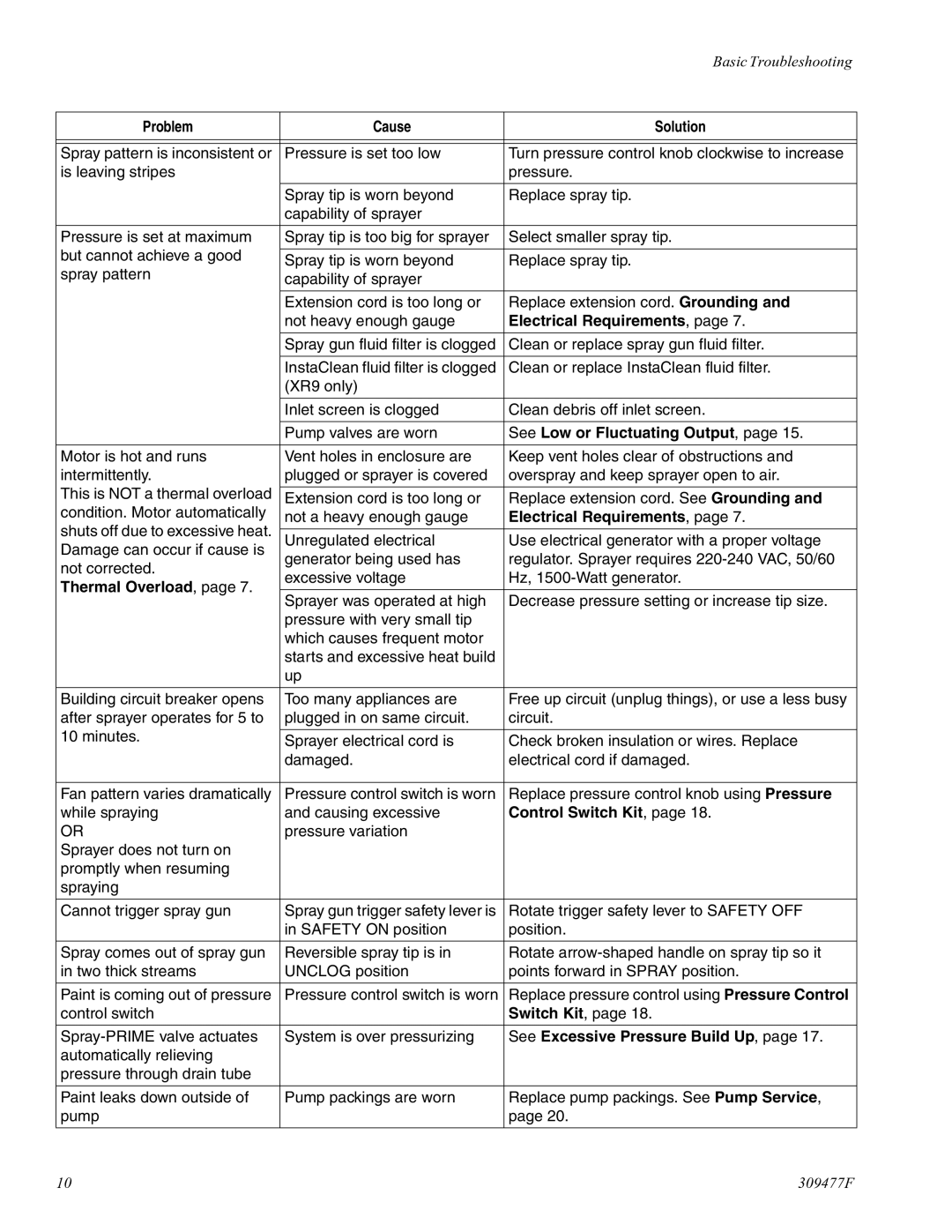

Problem | Cause | Solution | |

|

|

| |

|

|

| |

Spray pattern is inconsistent or | Pressure is set too low | Turn pressure control knob clockwise to increase | |

is leaving stripes |

| pressure. | |

|

|

| |

| Spray tip is worn beyond | Replace spray tip. | |

| capability of sprayer |

| |

|

|

| |

Pressure is set at maximum | Spray tip is too big for sprayer | Select smaller spray tip. | |

but cannot achieve a good |

|

| |

Spray tip is worn beyond | Replace spray tip. | ||

spray pattern | |||

capability of sprayer |

| ||

|

| ||

|

|

| |

| Extension cord is too long or | Replace extension cord. Grounding and | |

| not heavy enough gauge | Electrical Requirements, page 7. | |

|

|

| |

| Spray gun fluid filter is clogged | Clean or replace spray gun fluid filter. | |

|

|

| |

| InstaClean fluid filter is clogged | Clean or replace InstaClean fluid filter. | |

| (XR9 only) |

| |

|

|

| |

| Inlet screen is clogged | Clean debris off inlet screen. | |

|

|

| |

| Pump valves are worn | See Low or Fluctuating Output, page 15. | |

|

|

| |

Motor is hot and runs | Vent holes in enclosure are | Keep vent holes clear of obstructions and | |

intermittently. | plugged or sprayer is covered | overspray and keep sprayer open to air. | |

This is NOT a thermal overload |

|

| |

Extension cord is too long or | Replace extension cord. See Grounding and | ||

condition. Motor automatically | not a heavy enough gauge | Electrical Requirements, page 7. | |

shuts off due to excessive heat. |

|

| |

Unregulated electrical | Use electrical generator with a proper voltage | ||

Damage can occur if cause is | generator being used has | regulator. Sprayer requires | |

not corrected. | |||

excessive voltage | Hz, | ||

Thermal Overload, page 7. | |||

|

| ||

Sprayer was operated at high | Decrease pressure setting or increase tip size. | ||

| |||

| pressure with very small tip |

| |

| which causes frequent motor |

| |

| starts and excessive heat build |

| |

| up |

| |

|

|

| |

Building circuit breaker opens | Too many appliances are | Free up circuit (unplug things), or use a less busy | |

after sprayer operates for 5 to | plugged in on same circuit. | circuit. | |

10 minutes. |

|

| |

Sprayer electrical cord is | Check broken insulation or wires. Replace | ||

| |||

| damaged. | electrical cord if damaged. | |

|

|

| |

Fan pattern varies dramatically | Pressure control switch is worn | Replace pressure control knob using Pressure | |

while spraying | and causing excessive | Control Switch Kit, page 18. | |

OR | pressure variation |

| |

Sprayer does not turn on |

|

| |

promptly when resuming |

|

| |

spraying |

|

| |

|

|

| |

Cannot trigger spray gun | Spray gun trigger safety lever is | Rotate trigger safety lever to SAFETY OFF | |

| in SAFETY ON position | position. | |

|

|

| |

Spray comes out of spray gun | Reversible spray tip is in | Rotate | |

in two thick streams | UNCLOG position | points forward in SPRAY position. | |

|

|

| |

Paint is coming out of pressure | Pressure control switch is worn | Replace pressure control using Pressure Control | |

control switch |

| Switch Kit, page 18. | |

|

|

| |

System is over pressurizing | See Excessive Pressure Build Up, page 17. | ||

automatically relieving |

|

| |

pressure through drain tube |

|

| |

|

|

| |

Paint leaks down outside of | Pump packings are worn | Replace pump packings. See Pump Service, | |

pump |

| page 20. | |

|

|

|

10 | 309477F |