Installation Manual For Indoor Unit

Installation Manual For Indoor Unit

10. The operation method of fan controller

Through the fan controller switch in the electric box, the air volume of this unit can be continuously adjusted.

It is unnecessary to adjust air volume through the duct side wind level (unit outside static adjustment). The air volume set should be in the operation air volume range.

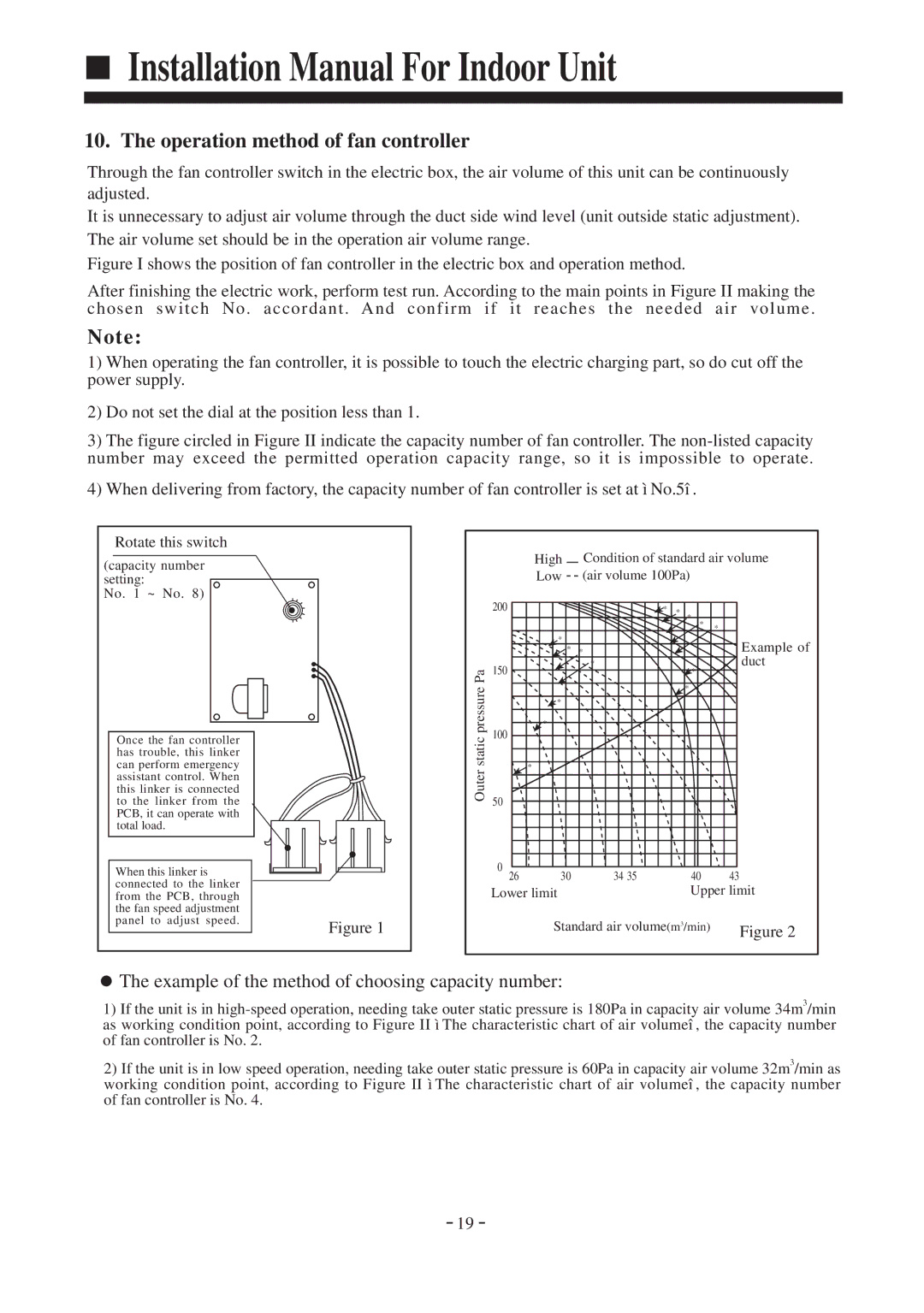

Figure I shows the position of fan controller in the electric box and operation method.

After finishing the electric work, perform test run. According to the main points in Figure II making the chosen switch No. accordant. And confirm if it reaches the needed air volume.

Note:

1)When operating the fan controller, it is possible to touch the electric charging part, so do cut off the power supply.

2)Do not set the dial at the position less than 1.

3)The figure circled in Figure II indicate the capacity number of fan controller. The non-listed capacity number may exceed the permitted operation capacity range, so it is impossible to operate.

4)When delivering from factory, the capacity number of fan controller is set at ìNo.5î.

Rotate this switch

(capacity number setting:

No. 1 ~ No. 8)

Once the fan controller has trouble, this linker can perform emergency assistant control. When this linker is connected to the linker from the PCB, it can operate with total load.

When this linker is connected to the linker from the PCB, through the fan speed adjustment panel to adjust speed.

Figure 1

|

|

|

| High |

| Condition of standard air volume | ||||||||||||||

|

|

|

|

| ||||||||||||||||

|

|

|

| Low | (air volume 100Pa) |

|

|

| ||||||||||||

| 200 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| * | * | * |

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| * | * |

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

| * |

|

|

|

|

|

|

|

|

|

|

|

|

| Example of |

|

|

|

|

|

|

| * | * |

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| duct |

Pa | 150 |

|

|

|

|

|

|

| * |

|

|

|

|

|

| * |

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

pressure |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| * |

|

|

|

|

|

|

|

|

| * |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

static | 100 |

|

|

| * |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

| * |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

Outer |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

50 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| 0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| 26 | 30 | 34 35 |

|

|

| 40 | 43 | ||||||||||||

| Lower limit |

|

|

|

|

|

|

| Upper limit | |||||||||||

|

|

|

|

|

| Standard air volume(m3/min) |

|

| Figure 2 | |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The example of the method of choosing capacity number:

The example of the method of choosing capacity number:

1)If the unit is in

2)If the unit is in low speed operation, needing take outer static pressure is 60Pa in capacity air volume 32m3/min as working condition point, according to Figure II ìThe characteristic chart of air volumeî, the capacity number of fan controller is No. 4.

19