Wire Feed | Tension Adjusting |

|

| |

Adjusting |

|

| Wire Sheath | |

| Screw (37) |

| ||

|

| |||

Spring (36) |

|

| ||

|

|

| ||

Cover (31)

Handle (30)

Cover

Locking

Spring (8)

Wire

Reel

(27)

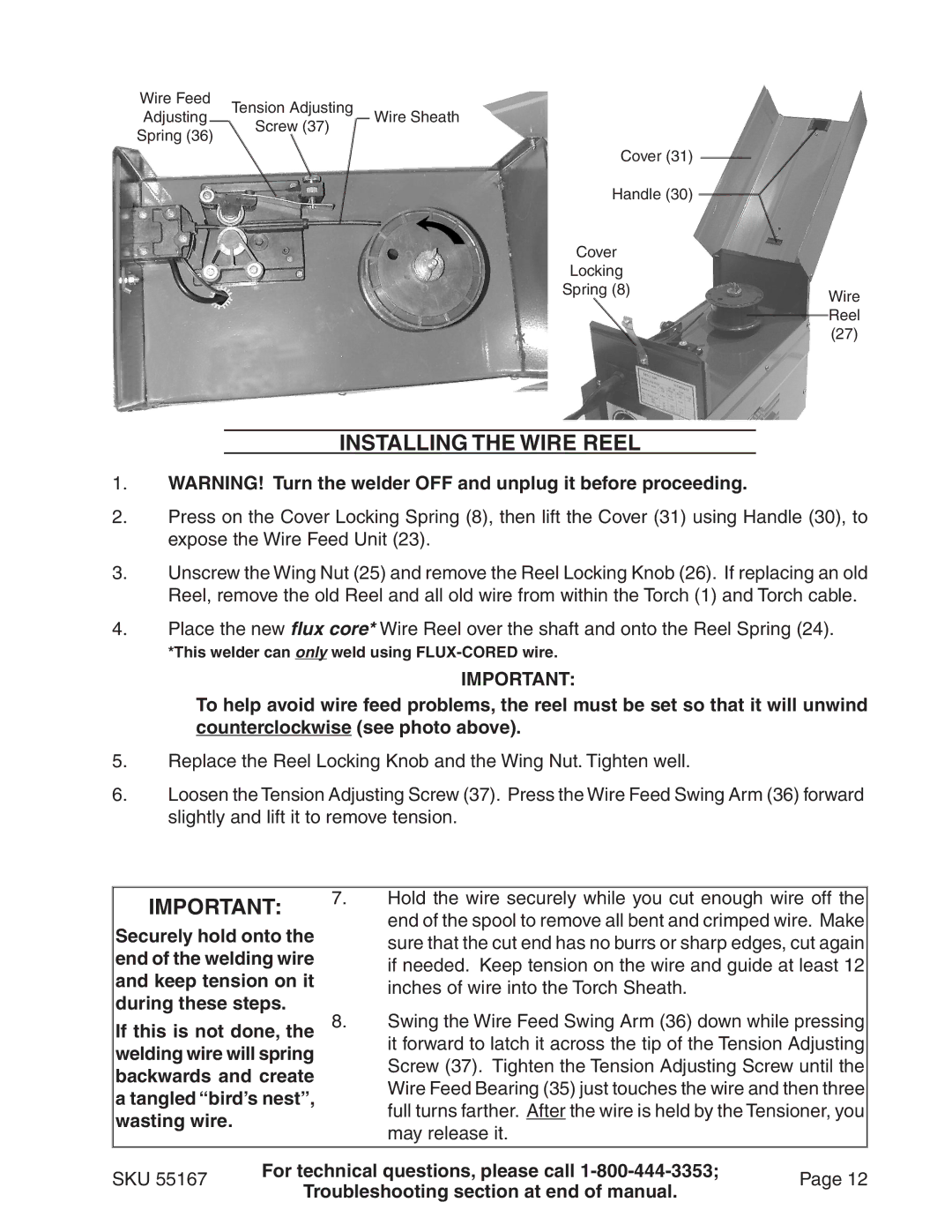

Installing the Wire Reel

1.WARNING! Turn the welder OFF and unplug it before proceeding.

2.Press on the Cover Locking Spring (8), then lift the Cover (31) using Handle (30), to expose the Wire Feed Unit (23).

3.Unscrew the Wing Nut (25) and remove the Reel Locking Knob (26). If replacing an old Reel, remove the old Reel and all old wire from within the Torch (1) and Torch cable.

4.Place the new flux core* Wire Reel over the shaft and onto the Reel Spring (24).

*This welder can only weld using

Important:

To help avoid wire feed problems, the reel must be set so that it will unwind counterclockwise (see photo above).

5.Replace the Reel Locking Knob and the Wing Nut. Tighten well.

6.Loosen the Tension Adjusting Screw (37). Press the Wire Feed Swing Arm (36) forward slightly and lift it to remove tension.

IMPORTANT:

Securely hold onto the end of the welding wire and keep tension on it during these steps.

If this is not done, the welding wire will spring backwards and create a tangled “bird’s nest”, wasting wire.

7.Hold the wire securely while you cut enough wire off the end of the spool to remove all bent and crimped wire. Make sure that the cut end has no burrs or sharp edges, cut again if needed. Keep tension on the wire and guide at least 12 inches of wire into the Torch Sheath.

8.Swing the Wire Feed Swing Arm (36) down while pressing it forward to latch it across the tip of the Tension Adjusting Screw (37). Tighten the Tension Adjusting Screw until the Wire Feed Bearing (35) just touches the wire and then three full turns farther. After the wire is held by the Tensioner, you may release it.

SKU 55167 | For technical questions, please call | Page 12 | |

Troubleshooting section at end of manual. | |||

|

|