6.Use respiratory protection when source controls cannot keep silica exposures below the recommended levels.

7.Provide periodic medical examinations for all workers who may be exposed to crystalline silica.

8.Post signs to warn workers about the hazard and to inform them about required protective equipment.

9.Provide workers with training that includes information about health effects, work practices, and protective equipment for crystalline silica.

10.Report all cases of silicosis to State health departments and to OSHA or the Mine Safety and Health Administration (MSHA).

31.![]() WARNING! The brass components of this product contain lead, a chemical known to the State of California to cause birth defects (or other reproductive harm). (California Health & Safety code § 25249.5, et seq.)

WARNING! The brass components of this product contain lead, a chemical known to the State of California to cause birth defects (or other reproductive harm). (California Health & Safety code § 25249.5, et seq.)

32.![]() WARNING! The warnings, cautions, and instructions discussed in this instruction manual cannot cover all possible conditions and situations that may occur. It must be understood by the operator that common sense and caution are factors which cannot be built into this product, but must be supplied by the operator.

WARNING! The warnings, cautions, and instructions discussed in this instruction manual cannot cover all possible conditions and situations that may occur. It must be understood by the operator that common sense and caution are factors which cannot be built into this product, but must be supplied by the operator.

33.Always connect this unit securely to an electrically grounded object (such as a water pipe or metal rod driven into the earth). If this unit is not grounded, a spark could potentially ignite a cloud of flammable dust, causing fire/explosion.

SAVE THESE INSTRUCTIONS

ASSEMBLY INSTRUCTIONS

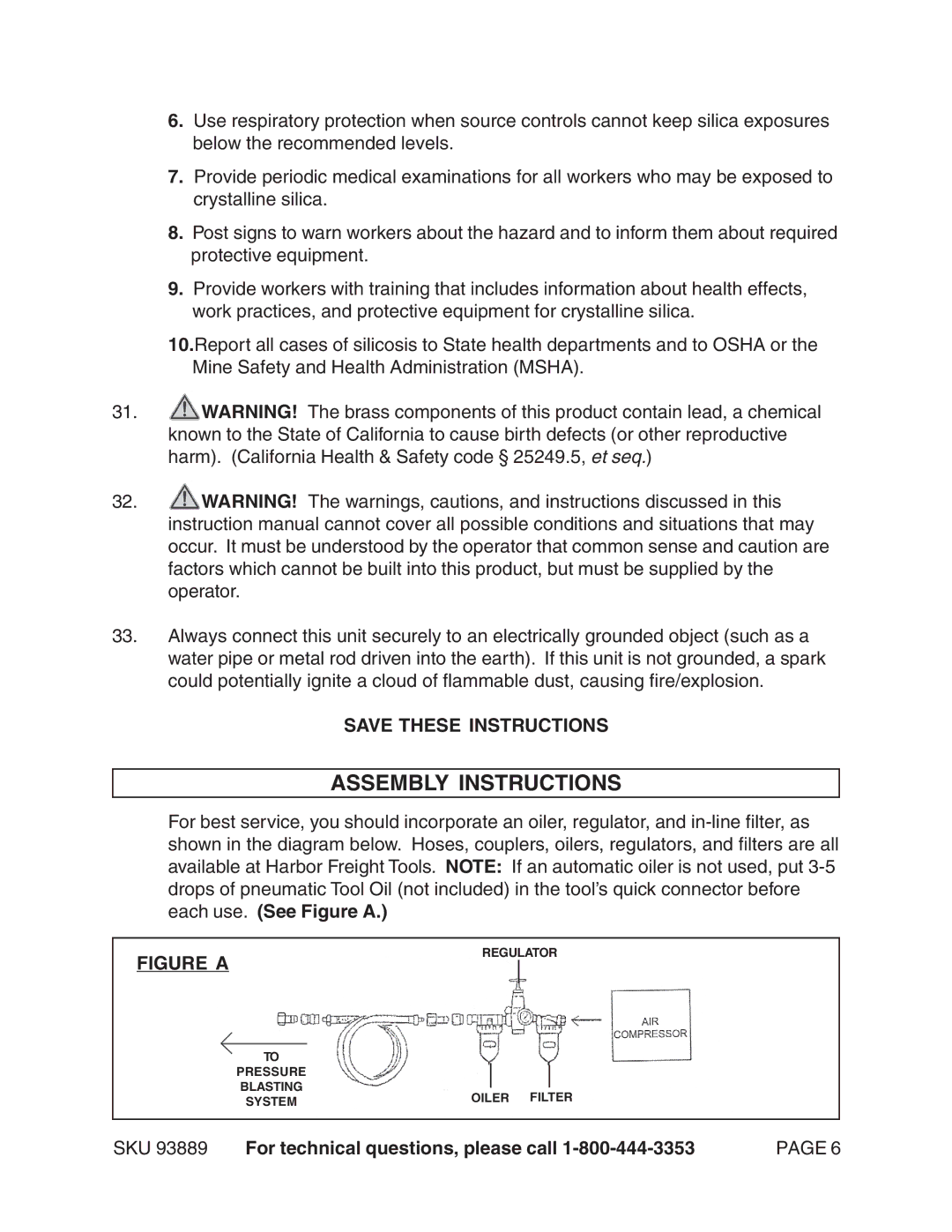

For best service, you should incorporate an oiler, regulator, and

FIGURE A

REGULATOR

TO |

| |

PRESSURE |

| |

BLASTING | OILER FILTER | |

SYSTEM | ||

|

SKU 93889 For technical questions, please call | PAGE 6 |