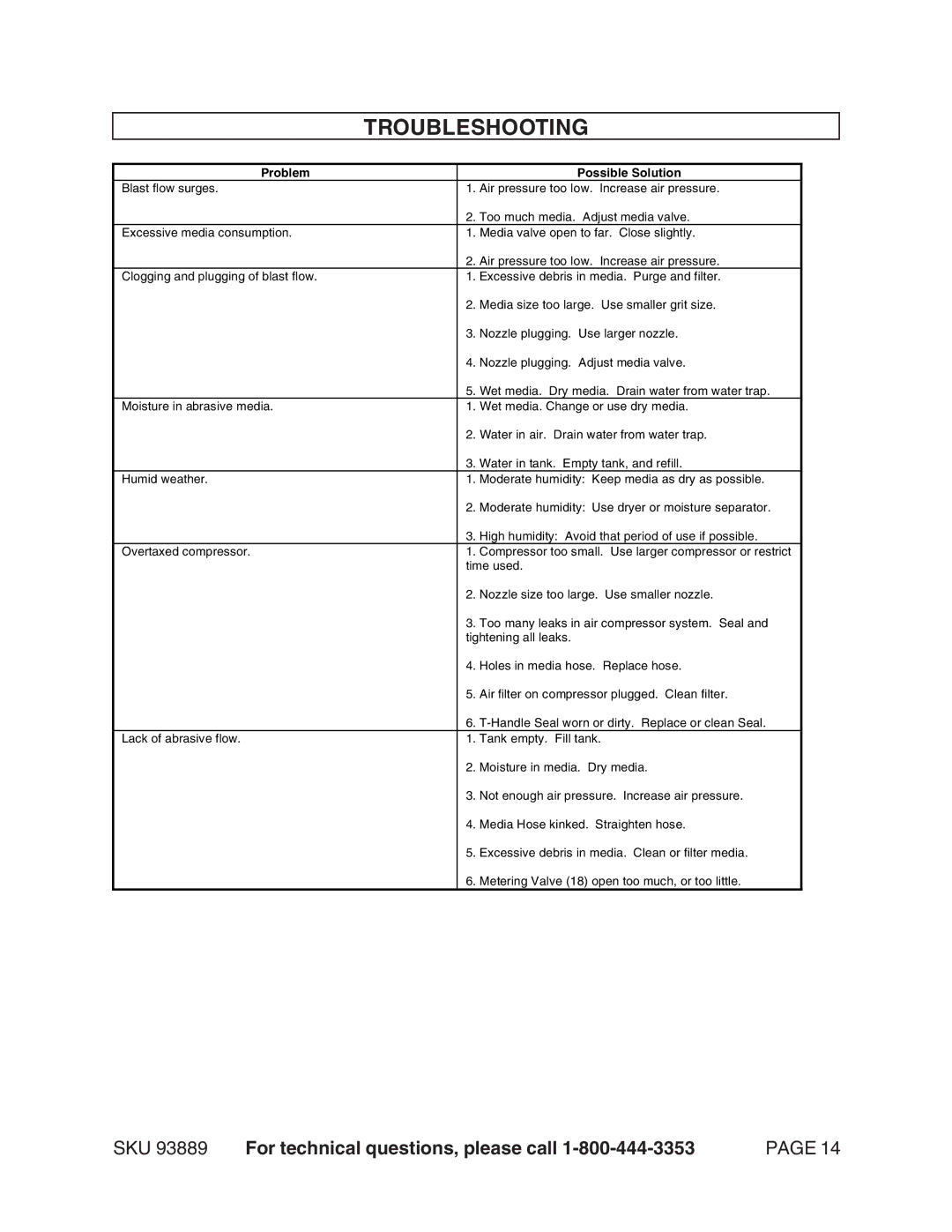

TROUBLESHOOTING

Problem |

| Possible Solution |

Blast flow surges. | 1. Air pressure too low. Increase air pressure. | |

| 2. | Too much media. Adjust media valve. |

Excessive media consumption. | 1. Media valve open to far. Close slightly. | |

| 2. | Air pressure too low. Increase air pressure. |

Clogging and plugging of blast flow. | 1. Excessive debris in media. Purge and filter. | |

| 2. | Media size too large. Use smaller grit size. |

| 3. | Nozzle plugging. Use larger nozzle. |

| 4. | Nozzle plugging. Adjust media valve. |

| 5. | Wet media. Dry media. Drain water from water trap. |

Moisture in abrasive media. | 1. Wet media. Change or use dry media. | |

| 2. | Water in air. Drain water from water trap. |

| 3. | Water in tank. Empty tank, and refill. |

Humid weather. | 1. Moderate humidity: Keep media as dry as possible. | |

| 2. | Moderate humidity: Use dryer or moisture separator. |

| 3. | High humidity: Avoid that period of use if possible. |

Overtaxed compressor. | 1. Compressor too small. Use larger compressor or restrict | |

| time used. | |

| 2. | Nozzle size too large. Use smaller nozzle. |

| 3. | Too many leaks in air compressor system. Seal and |

| tightening all leaks. | |

| 4. | Holes in media hose. Replace hose. |

| 5. | Air filter on compressor plugged. Clean filter. |

| 6. | |

Lack of abrasive flow. | 1. Tank empty. Fill tank. | |

| 2. | Moisture in media. Dry media. |

| 3. | Not enough air pressure. Increase air pressure. |

| 4. | Media Hose kinked. Straighten hose. |

| 5. | Excessive debris in media. Clean or filter media. |

| 6. | Metering Valve (18) open too much, or too little. |

SKU 93889 For technical questions, please call | PAGE 14 |