R

Cumberland Gap Wood Stove

CHIMNEY HEIGHT REQUIREMENTS / DRAFT

To be sure that your

This stove was designed for and tested on a 6” (152mm) chimney, 12

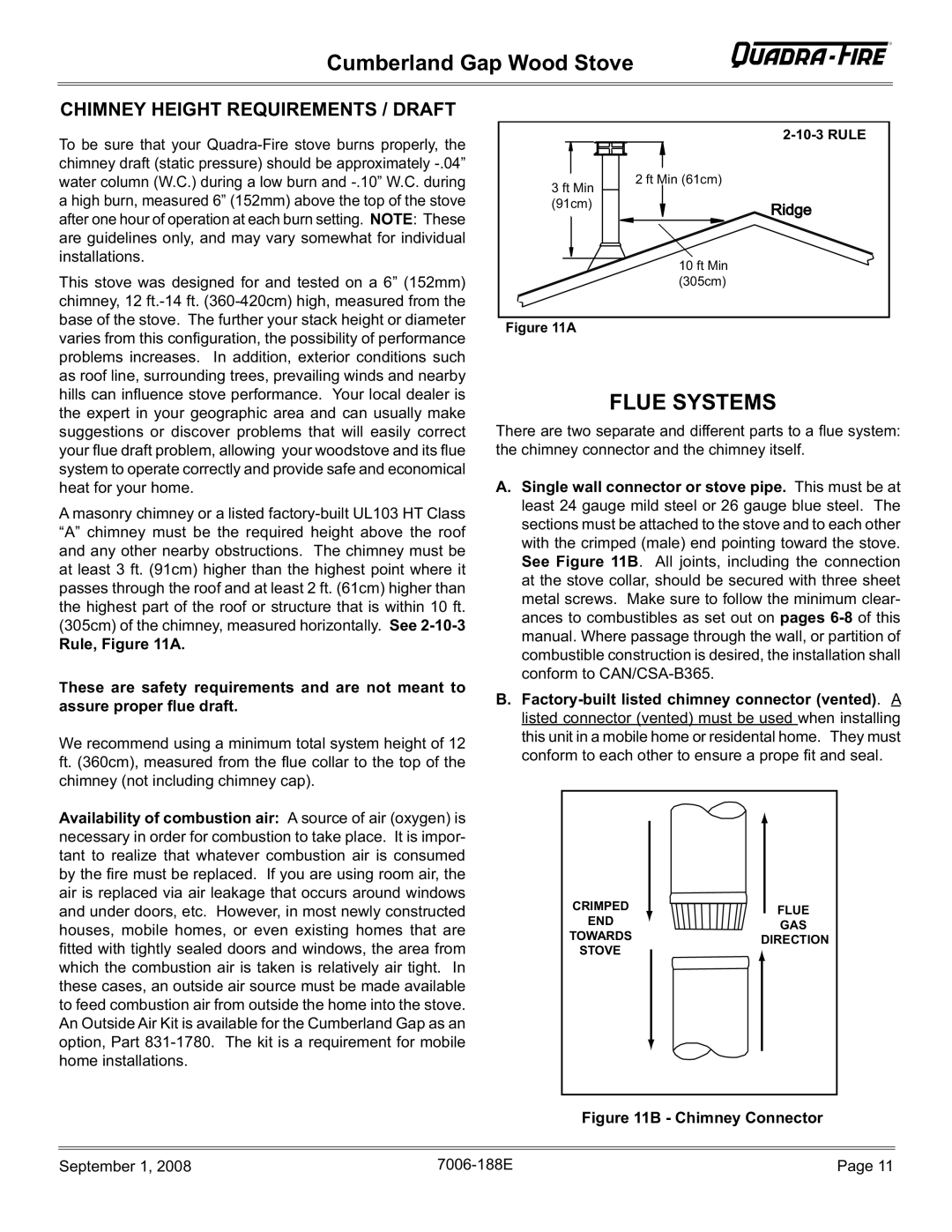

A masonry chimney or a listed

Rule, Figure 11A.

These are safety requirements and are not meant to assure proper flue draft.

We recommend using a minimum total system height of 12 ft. (360cm), measured from the flue collar to the top of the chimney (not including chimney cap).

Availability of combustion air: A source of air (oxygen) is necessary in order for combustion to take place. It is impor- tant to realize that whatever combustion air is consumed by the fire must be replaced. If you are using room air, the air is replaced via air leakage that occurs around windows and under doors, etc. However, in most newly constructed houses, mobile homes, or even existing homes that are fitted with tightly sealed doors and windows, the area from which the combustion air is taken is relatively air tight. In these cases, an outside air source must be made available to feed combustion air from outside the home into the stove. An Outside Air Kit is available for the Cumberland Gap as an option, Part

2 ft Min (61cm) |

3 ft Min |

(91cm) |

10 ft Min |

(305cm) |

Figure 11A

FLUE SYSTEMS

There are two separate and different parts to a flue system: the chimney connector and the chimney itself.

A.Single wall connector or stove pipe. This must be at least 24 gauge mild steel or 26 gauge blue steel. The sections must be attached to the stove and to each other with the crimped (male) end pointing toward the stove. See Figure 11B. All joints, including the connection at the stove collar, should be secured with three sheet metal screws. Make sure to follow the minimum clear- ances to combustibles as set out on pages

B.

CRIMPED | FLUE |

END | GAS |

TOWARDS | DIRECTION |

STOVE |

|

Figure 11B - Chimney Connector

September 1, 2008 | Page 11 |