Engineering Design Guide | HBH/V SERIES | Heat Controller, Inc. |

HBH & HBV COMPACT Horizontal & Vertical HFC-410a Units

Entering Water Temperature Range: 20 - 120°F

Horizontal Water Source Heat Pump |

|

| Vertical Water Source Heat Pump | |||||||||

Sizes |

|

|

|

|

|

|

| Sizes |

|

| ||

|

|

|

|

|

|

|

|

| 006 |

|

|

|

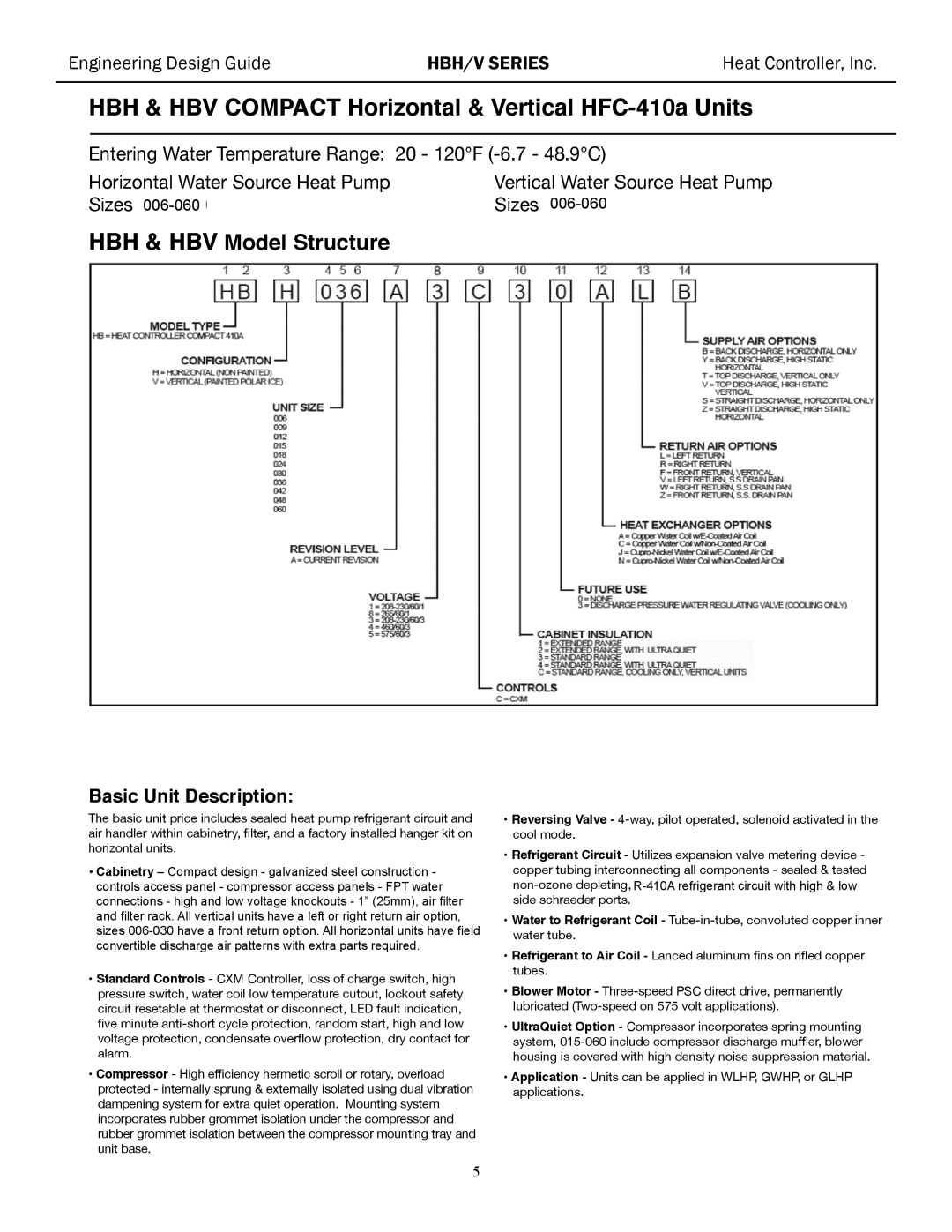

HBH & HBV Model Structure |

|

|

|

|

|

|

| |||||

1 | 2 | 3 | 4 | 5 | 6 | 7 | 9 | 10 | 11 | 12 | 13 | 14 |

H B H 0 3 6 A 3 C 3 0 A L B

MODEL TYPE

HB = HEAT CONTROLLER COMPACT 410A

CONFIGURATION

H = HORIZONTAL (NON PAINTED) }

V = VERTICAL (PAINTED POLAR ICE)

UNIT SIZE

015 - 1,8

018 - 1,8

024 - 1,3,4,8

030 - 1,3,4,8 Voltage Code

036 - 1,3,4,8

042 - 1,3,4,5

048 - 1,3,4,5

060 - 1,3,4,5

SUPPLY AIR OPTIONS

B = BACK DISCHARGE, HORIZONTAL ONLY Y = BACK DISCHARGE, HIGH STATIC

HORIZONTAL 018 - 060

T = TOP DISCHARGE, VERTICAL ONLY V = TOP DISCHARGE, HIGH STATIC

VERTICAL 018 - 060

S = STRAIGHT DISCHARGE, HORIZONTAL ONLY Z = STRAIGHT DISCHARGE, HIGH STATIC

HORIZONTAL 018 - 060

RETURN AIR OPTIONS

L = LEFT RETURN

R = RIGHT RETURN

F = FRONT RETURN, VERTICAL

V = LEFT RETURN, S.S DRAIN PAN W = RIGHT RETURN, S.S DRAIN PAN

Z = FRONT RETURN, S.S. DRAIN PAN

REVISION LEVEL

A = CURRENT REVISION FOR SIZES 006 - 060

VOLTAGE

1 =

8 = 265/60/1

3 =

4 = 460/60/3

5 = 575/60/3

Basic Unit Description:

HEAT EXCHANGER OPTIONS

A = Copper Water Coil

C = Copper Water Coil

J =

N =

FUTURE USE

0 = NONE

3 = DISCHARGE PRESSURE WATER REGULATING VALVE (COOLING ONLY) NOTAVAILABLE ON UNIT SIZES 006, 009 AND 012

CABINET INSULATION

3 = STANDARD RANGE

4 = STANDARD RANGE, WITH ULTRA QUIET

C = STANDARD RANGE, COOLING ONLY, VERTICAL UNITS

CONTROLS

C = CXM

The basic unit price includes sealed heat pump refrigerant circuit and air handler within cabinetry, lter, and a factory installed hanger kit on horizontal units.

•Cabinetry

•Standard Controls - CXM Controller, loss of charge switch, high pressure switch, water coil low temperature cutout, lockout safety circuit resetable at thermostat or disconnect, LED fault indication, ve minute

•Compressor - High efciency hermetic scroll or rotary, overload protected - internally sprung & externally isolated using dual vibration dampening system for extra quiet operation. Mounting system incorporates rubber grommet isolation under the compressor and rubber grommet isolation between the compressor mounting tray and unit base.

•Reversing Valve -

•Refrigerant Circuit - Utilizes expansion valve metering device - copper tubing interconnecting all components - sealed & tested

•Water to Refrigerant Coil -

•Refrigerant to Air Coil - Lanced aluminum ns on ried copper tubes.

•Blower Motor -

•UltraQuiet Option - Compressor incorporates spring mounting system,

•Application - Units can be applied in WLHP, GWHP, or GLHP applications.

5