Installation and Operations Manual

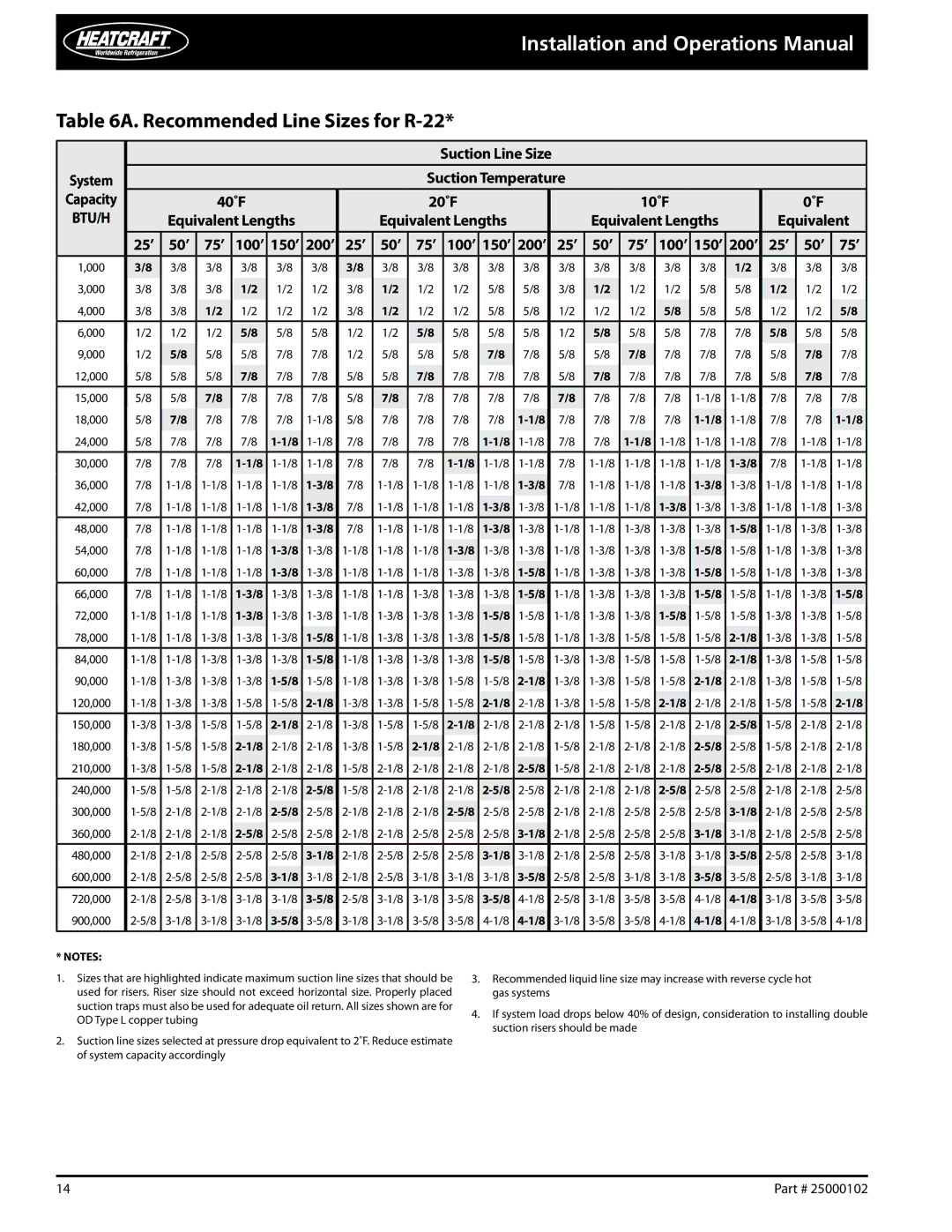

Table 6A. Recommended Line Sizes for R-22*

|

|

|

|

|

|

|

|

|

| Suction Line Size |

|

|

|

|

|

|

|

|

| ||||

System |

|

|

|

|

|

|

|

| Suction Temperature |

|

|

|

|

|

|

|

| ||||||

Capacity |

|

| 40˚F |

|

|

|

| 20˚F |

|

|

|

|

| 10˚F |

|

|

| 0˚F |

| ||||

BTU/H |

| Equivalent Lengths |

|

| Equivalent Lengths |

|

|

| Equivalent Lengths |

| Equivalent | ||||||||||||

| 25’ | 50’ | 75’ | 100’ | 150’ | 200’ | 25’ | 50’ | 75’ |

| 100’ | 150’ | 200’ |

| 25’ | 50’ | 75’ | 100’ | 150’ | 200’ | 25’ | 50’ | 75’ |

1,000 | 3/8 | 3/8 | 3/8 | 3/8 | 3/8 | 3/8 | 3/8 | 3/8 | 3/8 |

| 3/8 | 3/8 | 3/8 |

| 3/8 | 3/8 | 3/8 | 3/8 | 3/8 | 1/2 | 3/8 | 3/8 | 3/8 |

3,000 | 3/8 | 3/8 | 3/8 | 1/2 | 1/2 | 1/2 | 3/8 | 1/2 | 1/2 |

| 1/2 | 5/8 | 5/8 |

| 3/8 | 1/2 | 1/2 | 1/2 | 5/8 | 5/8 | 1/2 | 1/2 | 1/2 |

4,000 | 3/8 | 3/8 | 1/2 | 1/2 | 1/2 | 1/2 | 3/8 | 1/2 | 1/2 |

| 1/2 | 5/8 | 5/8 |

| 1/2 | 1/2 | 1/2 | 5/8 | 5/8 | 5/8 | 1/2 | 1/2 | 5/8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6,000 | 1/2 | 1/2 | 1/2 | 5/8 | 5/8 | 5/8 | 1/2 | 1/2 | 5/8 |

| 5/8 | 5/8 | 5/8 |

| 1/2 | 5/8 | 5/8 | 5/8 | 7/8 | 7/8 | 5/8 | 5/8 | 5/8 |

9,000 | 1/2 | 5/8 | 5/8 | 5/8 | 7/8 | 7/8 | 1/2 | 5/8 | 5/8 |

| 5/8 | 7/8 | 7/8 |

| 5/8 | 5/8 | 7/8 | 7/8 | 7/8 | 7/8 | 5/8 | 7/8 | 7/8 |

12,000 | 5/8 | 5/8 | 5/8 | 7/8 | 7/8 | 7/8 | 5/8 | 5/8 | 7/8 |

| 7/8 | 7/8 | 7/8 |

| 5/8 | 7/8 | 7/8 | 7/8 | 7/8 | 7/8 | 5/8 | 7/8 | 7/8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15,000 | 5/8 | 5/8 | 7/8 | 7/8 | 7/8 | 7/8 | 5/8 | 7/8 | 7/8 |

| 7/8 | 7/8 | 7/8 |

| 7/8 | 7/8 | 7/8 | 7/8 | 7/8 | 7/8 | 7/8 | ||

18,000 | 5/8 | 7/8 | 7/8 | 7/8 | 7/8 | 5/8 | 7/8 | 7/8 |

| 7/8 | 7/8 |

| 7/8 | 7/8 | 7/8 | 7/8 | 7/8 | 7/8 | |||||

24,000 | 5/8 | 7/8 | 7/8 | 7/8 | 7/8 | 7/8 | 7/8 |

| 7/8 |

| 7/8 | 7/8 | 7/8 | ||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

30,000 | 7/8 | 7/8 | 7/8 | 7/8 | 7/8 | 7/8 |

|

| 7/8 | 7/8 | |||||||||||||

36,000 | 7/8 | 7/8 |

|

| 7/8 | ||||||||||||||||||

42,000 | 7/8 | 7/8 |

|

| |||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

48,000 | 7/8 | 7/8 |

|

| |||||||||||||||||||

54,000 | 7/8 |

|

| ||||||||||||||||||||

60,000 | 7/8 |

|

| ||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

66,000 | 7/8 |

|

| ||||||||||||||||||||

72,000 |

|

| |||||||||||||||||||||

78,000 |

|

| |||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

84,000 |

|

| |||||||||||||||||||||

90,000 |

|

| |||||||||||||||||||||

120,000 |

|

| |||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

150,000 |

|

| |||||||||||||||||||||

180,000 |

|

| |||||||||||||||||||||

210,000 |

|

| |||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

240,000 |

|

| |||||||||||||||||||||

300,000 |

|

| |||||||||||||||||||||

360,000 |

|

| |||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

480,000 |

|

| |||||||||||||||||||||

600,000 |

|

| |||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

720,000 |

|

| |||||||||||||||||||||

900,000 |

|

| |||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

* NOTES:

1.Sizes that are highlighted indicate maximum suction line sizes that should be used for risers. Riser size should not exceed horizontal size. Properly placed suction traps must also be used for adequate oil return. All sizes shown are for OD Type L copper tubing

2.Suction line sizes selected at pressure drop equivalent to 2˚F. Reduce estimate of system capacity accordingly

3.Recommended liquid line size may increase with reverse cycle hot gas systems

4.If system load drops below 40% of design, consideration to installing double suction risers should be made

14 | Part # 25000102 |