|

|

|

|

|

|

|

|

|

|

|

| Installation and Operations Manual | |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

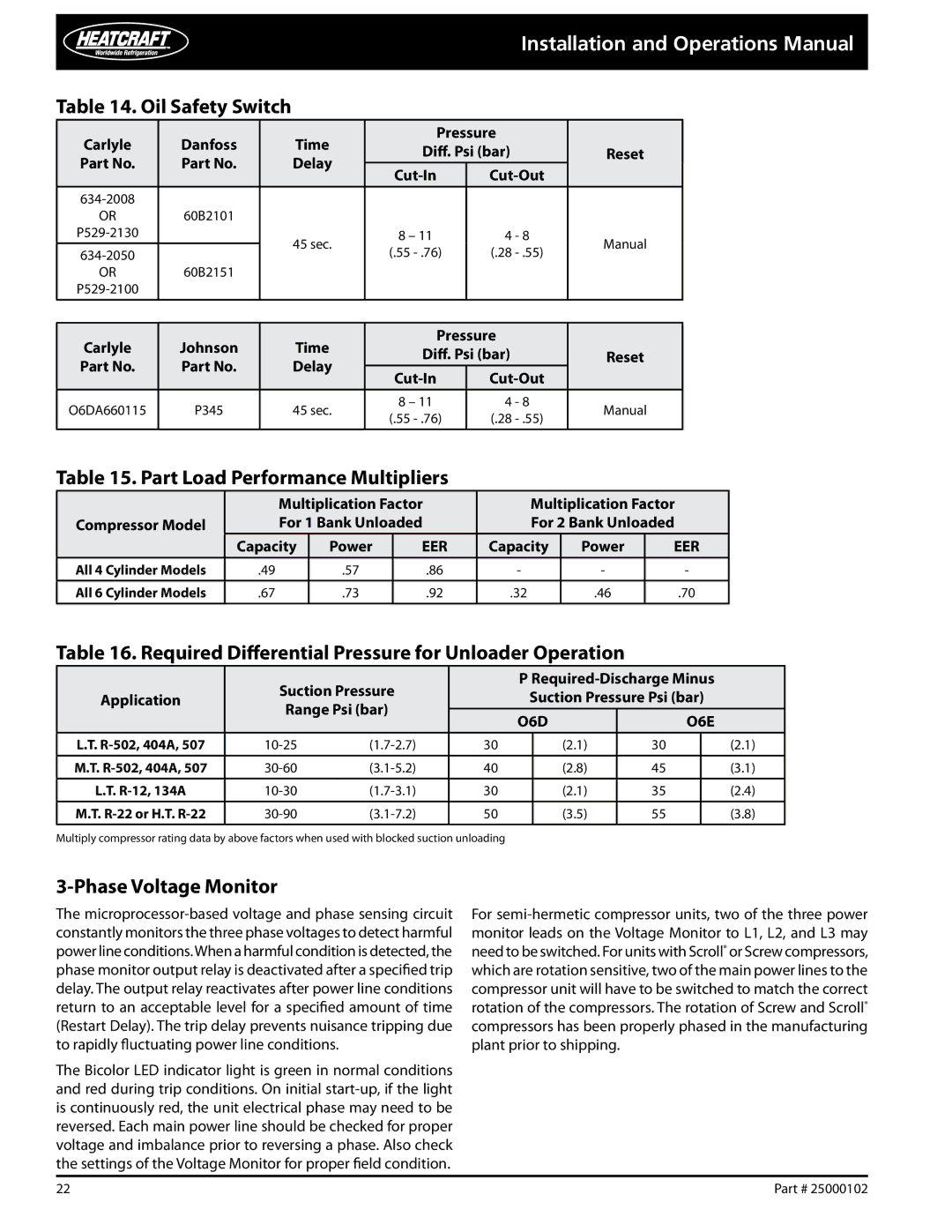

Table 14. Oil Safety Switch |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

Carlyle | Danfoss |

| Time |

|

|

| Pressure |

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

| Diff. Psi (bar) |

| Reset |

|

|

|

|

|

| |||||||||||

Part No. | Part No. |

| Delay |

|

|

|

|

|

|

|

|

| |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

OR | 60B2101 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

| 45 sec. |

|

| 8 – 11 | 4 - 8 |

|

| Manual |

|

|

|

|

|

| |||||||

|

|

|

| (.55 |

| (.28 |

|

|

|

|

|

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

OR | 60B2151 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

Carlyle | Johnson |

| Time |

|

|

| Pressure |

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

| Diff. Psi (bar) |

| Reset |

|

|

|

|

|

| |||||||||||

Part No. | Part No. |

| Delay |

|

|

|

|

|

|

|

|

| |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

O6DA660115 | P345 |

| 45 sec. |

|

| 8 – 11 | 4 - 8 |

|

| Manual |

|

|

|

|

|

| |||||||

|

| (.55 |

| (.28 |

|

|

|

|

|

|

| ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

Table 15. Part Load Performance Multipliers |

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||

|

|

|

| Multiplication Factor |

| Multiplication Factor |

|

| |||||||||||||||

Compressor Model |

|

| For 1 Bank Unloaded |

| For 2 Bank Unloaded |

|

| ||||||||||||||||

|

| Capacity |

| Power |

| EER |

| Capacity |

| Power |

|

| EER |

|

| ||||||||

All 4 Cylinder Models |

| .49 |

| .57 |

|

| .86 |

|

| - |

| - |

|

|

| - |

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

All 6 Cylinder Models |

| .67 |

| .73 |

|

| .92 |

|

| .32 |

| .46 |

|

|

| .70 |

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||

Table 16. Required Differential Pressure for Unloader Operation |

|

|

|

|

|

| |||||||||||||||||

|

|

|

| Suction Pressure |

|

| P |

| |||||||||||||||

Application |

|

|

|

| Suction Pressure Psi (bar) |

| |||||||||||||||||

|

| Range Psi (bar) |

|

|

|

|

| ||||||||||||||||

|

|

|

|

|

|

|

| O6D |

|

|

|

|

|

| O6E |

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

L.T. |

|

|

| 30 |

| (2.1) |

|

| 30 |

| (2.1) |

| |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||

M.T. |

|

|

| 40 |

| (2.8) |

|

| 45 |

| (3.1) |

| |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||

L.T. |

|

|

| 30 |

| (2.1) |

|

| 35 |

| (2.4) |

| |||||||||||

M.T. |

|

|

| 50 |

| (3.5) |

|

| 55 |

| (3.8) |

| |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Multiply compressor rating data by above factors when used with blocked suction unloading

3-Phase Voltage Monitor

The

The Bicolor LED indicator light is green in normal conditions and red during trip conditions. On initial

For

22 | Part # 25000102 |