Parallel Compressor Systems

Sight Glass & Moisture Indicator

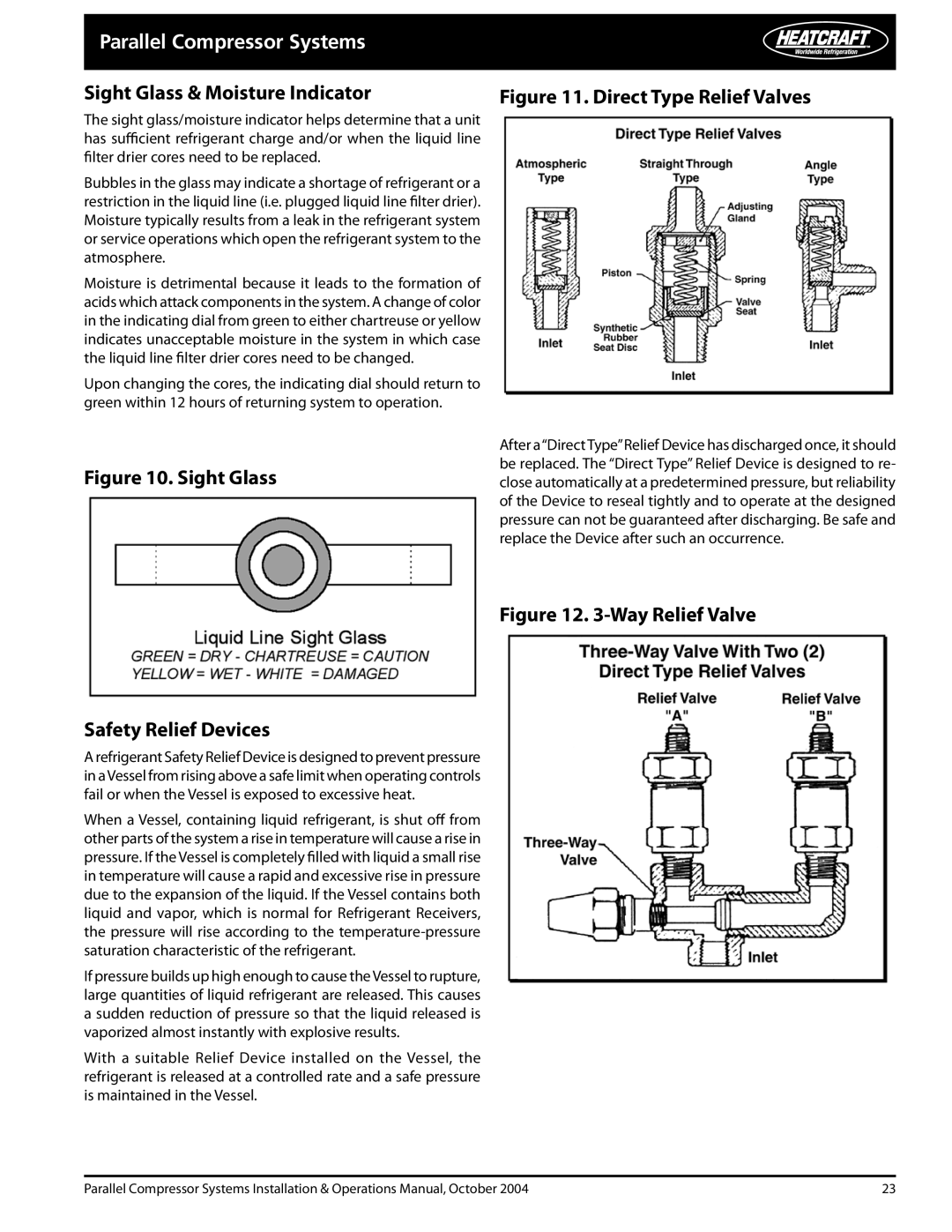

The sight glass/moisture indicator helps determine that a unit has sufficient refrigerant charge and/or when the liquid line filter drier cores need to be replaced.

Bubbles in the glass may indicate a shortage of refrigerant or a restriction in the liquid line (i.e. plugged liquid line filter drier). Moisture typically results from a leak in the refrigerant system or service operations which open the refrigerant system to the atmosphere.

Moisture is detrimental because it leads to the formation of acids which attack components in the system. A change of color in the indicating dial from green to either chartreuse or yellow indicates unacceptable moisture in the system in which case the liquid line filter drier cores need to be changed.

Upon changing the cores, the indicating dial should return to green within 12 hours of returning system to operation.

Figure 10. Sight Glass

Safety Relief Devices

A refrigerant Safety Relief Device is designed to prevent pressure in a Vessel from rising above a safe limit when operating controls fail or when the Vessel is exposed to excessive heat.

When a Vessel, containing liquid refrigerant, is shut off from other parts of the system a rise in temperature will cause a rise in pressure. If the Vessel is completely filled with liquid a small rise in temperature will cause a rapid and excessive rise in pressure due to the expansion of the liquid. If the Vessel contains both liquid and vapor, which is normal for Refrigerant Receivers, the pressure will rise according to the

If pressure builds up high enough to cause the Vessel to rupture, large quantities of liquid refrigerant are released. This causes a sudden reduction of pressure so that the liquid released is vaporized almost instantly with explosive results.

With a suitable Relief Device installed on the Vessel, the refrigerant is released at a controlled rate and a safe pressure is maintained in the Vessel.

Figure 11. Direct Type Relief Valves

After a“Direct Type”Relief Device has discharged once, it should be replaced. The “Direct Type” Relief Device is designed to re- close automatically at a predetermined pressure, but reliability of the Device to reseal tightly and to operate at the designed pressure can not be guaranteed after discharging. Be safe and replace the Device after such an occurrence.

Figure 12. 3-Way Relief Valve

Parallel Compressor Systems Installation & Operations Manual, October 2004 | 23 |