|

|

| Installation and Operations Manual | ||

|

|

| |||

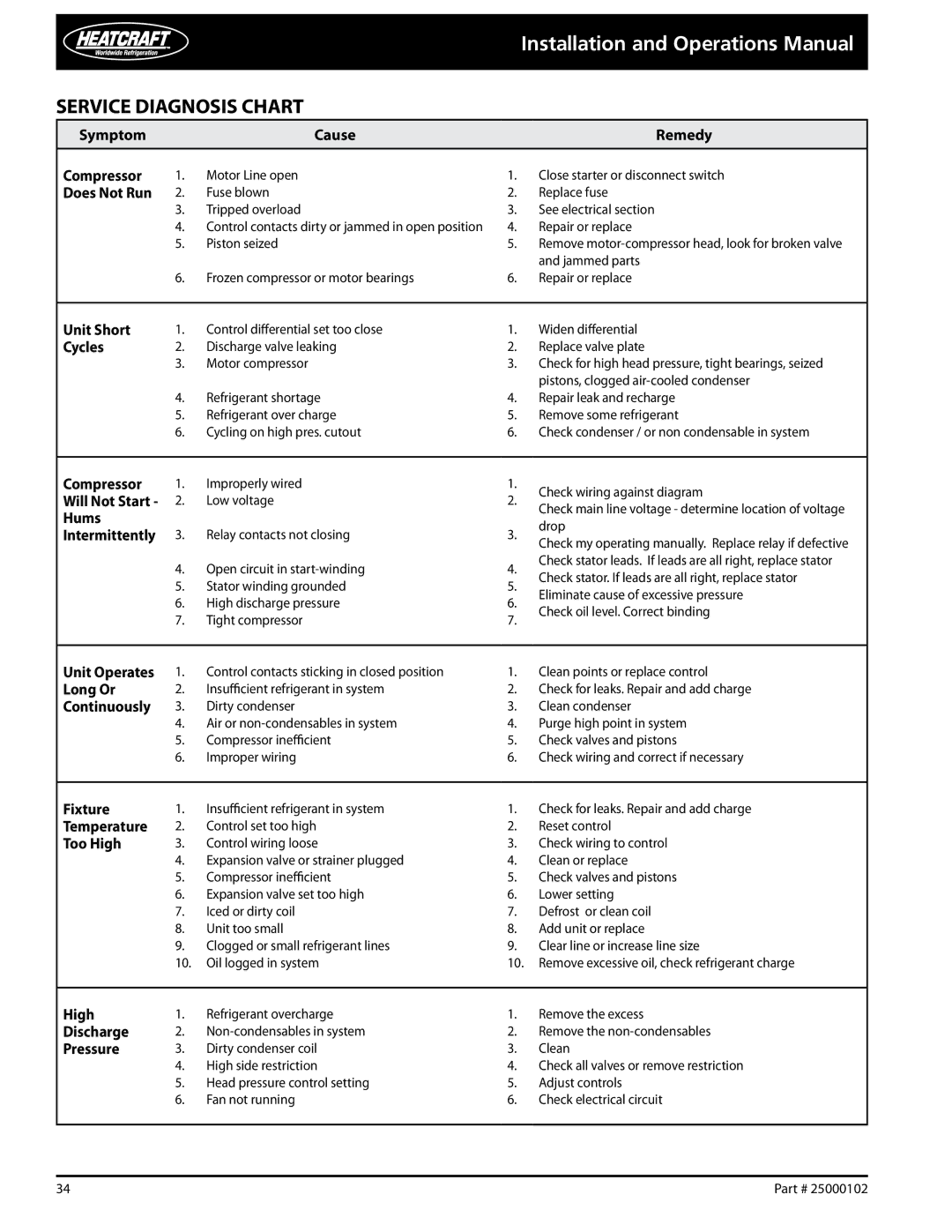

SERVICE DIAGNOSIS CHART |

|

| |||

Symptom |

| Cause |

| Remedy | |

|

|

|

|

| |

Compressor | 1. | Motor Line open | 1. | Close starter or disconnect switch | |

Does Not Run | 2. | Fuse blown | 2. | Replace fuse | |

| 3. | Tripped overload | 3. | See electrical section | |

| 4. | Control contacts dirty or jammed in open position | 4. | Repair or replace | |

| 5. | Piston seized | 5. | Remove | |

|

|

|

| and jammed parts | |

| 6. | Frozen compressor or motor bearings | 6. | Repair or replace | |

|

|

|

|

| |

Unit Short | 1. | Control differential set too close | 1. | Widen differential | |

Cycles | 2. | Discharge valve leaking | 2. | Replace valve plate | |

| 3. | Motor compressor | 3. | Check for high head pressure, tight bearings, seized | |

|

|

|

| pistons, clogged | |

| 4. | Refrigerant shortage | 4. | Repair leak and recharge | |

| 5. | Refrigerant over charge | 5. | Remove some refrigerant | |

| 6. | Cycling on high pres. cutout | 6. | Check condenser / or non condensable in system | |

|

|

|

|

| |

Compressor | 1. | Improperly wired | 1. | Check wiring against diagram | |

Will Not Start - | 2. | Low voltage | 2. | ||

Check main line voltage - determine location of voltage | |||||

Hums |

|

|

| ||

|

|

| drop | ||

Intermittently | 3. | Relay contacts not closing | 3. | ||

Check my operating manually. Replace relay if defective | |||||

|

|

|

| ||

| 4. | Open circuit in | 4. | Check stator leads. If leads are all right, replace stator | |

| Check stator. If leads are all right, replace stator | ||||

| 5. | Stator winding grounded | 5. | ||

| Eliminate cause of excessive pressure | ||||

| 6. | High discharge pressure | 6. | ||

| Check oil level. Correct binding | ||||

| 7. | Tight compressor | 7. | ||

|

| ||||

|

|

|

|

| |

Unit Operates | 1. | Control contacts sticking in closed position | 1. | Clean points or replace control | |

Long Or | 2. | Insufficient refrigerant in system | 2. | Check for leaks. Repair and add charge | |

Continuously | 3. | Dirty condenser | 3. | Clean condenser | |

| 4. | Air or | 4. | Purge high point in system | |

| 5. | Compressor inefficient | 5. | Check valves and pistons | |

| 6. | Improper wiring | 6. | Check wiring and correct if necessary | |

|

|

|

|

| |

Fixture | 1. | Insufficient refrigerant in system | 1. | Check for leaks. Repair and add charge | |

Temperature | 2. | Control set too high | 2. | Reset control | |

Too High | 3. | Control wiring loose | 3. | Check wiring to control | |

| 4. | Expansion valve or strainer plugged | 4. | Clean or replace | |

| 5. | Compressor inefficient | 5. | Check valves and pistons | |

| 6. | Expansion valve set too high | 6. | Lower setting | |

| 7. | Iced or dirty coil | 7. | Defrost or clean coil | |

| 8. | Unit too small | 8. | Add unit or replace | |

| 9. | Clogged or small refrigerant lines | 9. | Clear line or increase line size | |

| 10. | Oil logged in system | 10. | Remove excessive oil, check refrigerant charge | |

|

|

|

|

| |

High | 1. | Refrigerant overcharge | 1. | Remove the excess | |

Discharge | 2. | 2. | Remove the | ||

Pressure | 3. | Dirty condenser coil | 3. | Clean | |

| 4. | High side restriction | 4. | Check all valves or remove restriction | |

| 5. | Head pressure control setting | 5. | Adjust controls | |

| 6. | Fan not running | 6. | Check electrical circuit | |

|

|

|

|

| |

34 | Part # 25000102 |