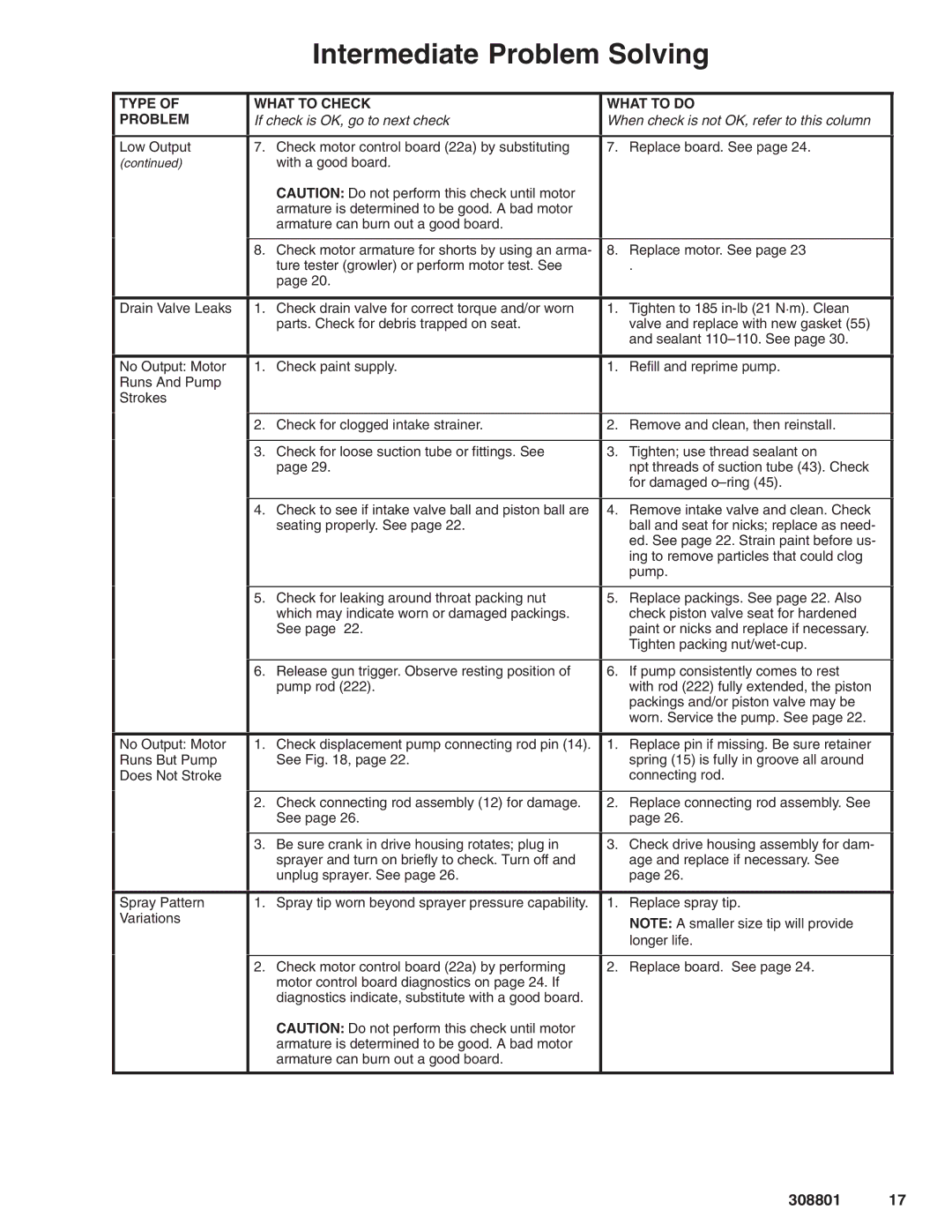

Intermediate Problem Solving

TYPE OF | WHAT TO CHECK | WHAT TO DO |

PROBLEM | If check is OK, go to next check | When check is not OK, refer to this column |

|

|

|

Low Output | 7. Check motor control board (22a) by substituting | 7. Replace board. See page 24. |

(continued) | with a good board. |

|

| CAUTION: Do not perform this check until motor |

|

| armature is determined to be good. A bad motor |

|

| armature can burn out a good board. |

|

|

|

|

8.Check motor armature for shorts by using an arma- ture tester (growler) or perform motor test. See page 20.

8.Replace motor. See page 23

.

Drain Valve Leaks | 1. | Check drain valve for correct torque and/or worn | 1. | Tighten to 185 |

|

| parts. Check for debris trapped on seat. |

| valve and replace with new gasket (55) |

|

|

|

| and sealant |

|

|

|

|

|

No Output: Motor | 1. | Check paint supply. | 1. | Refill and reprime pump. |

Runs And Pump |

|

|

|

|

Strokes |

|

|

|

|

|

|

|

|

|

| 2. | Check for clogged intake strainer. | 2. | Remove and clean, then reinstall. |

|

|

|

|

|

| 3. | Check for loose suction tube or fittings. See | 3. | Tighten; use thread sealant on |

|

| page 29. |

| npt threads of suction tube (43). Check |

|

|

|

| for damaged |

|

|

|

|

|

| 4. | Check to see if intake valve ball and piston ball are | 4. | Remove intake valve and clean. Check |

|

| seating properly. See page 22. |

| ball and seat for nicks; replace as need- |

|

|

|

| ed. See page 22. Strain paint before us- |

|

|

|

| ing to remove particles that could clog |

|

|

|

| pump. |

|

|

|

|

|

| 5. | Check for leaking around throat packing nut | 5. | Replace packings. See page 22. Also |

|

| which may indicate worn or damaged packings. |

| check piston valve seat for hardened |

|

| See page 22. |

| paint or nicks and replace if necessary. |

|

|

|

| Tighten packing |

|

|

|

|

|

| 6. | Release gun trigger. Observe resting position of | 6. | If pump consistently comes to rest |

|

| pump rod (222). |

| with rod (222) fully extended, the piston |

|

|

|

| packings and/or piston valve may be |

|

|

|

| worn. Service the pump. See page 22. |

|

|

|

|

|

No Output: Motor | 1. | Check displacement pump connecting rod pin (14). | 1. | Replace pin if missing. Be sure retainer |

Runs But Pump |

| See Fig. 18, page 22. |

| spring (15) is fully in groove all around |

Does Not Stroke |

|

|

| connecting rod. |

|

|

|

|

|

| 2. | Check connecting rod assembly (12) for damage. | 2. | Replace connecting rod assembly. See |

|

| See page 26. |

| page 26. |

|

|

|

|

|

| 3. | Be sure crank in drive housing rotates; plug in | 3. | Check drive housing assembly for dam- |

|

| sprayer and turn on briefly to check. Turn off and |

| age and replace if necessary. See |

|

| unplug sprayer. See page 26. |

| page 26. |

|

|

|

|

|

Spray Pattern | 1. | Spray tip worn beyond sprayer pressure capability. | 1. | Replace spray tip. |

Variations |

|

|

| NOTE: A smaller size tip will provide |

|

|

|

| |

|

|

|

| longer life. |

|

|

|

|

|

2.Check motor control board (22a) by performing motor control board diagnostics on page 24. If diagnostics indicate, substitute with a good board.

CAUTION: Do not perform this check until motor armature is determined to be good. A bad motor armature can burn out a good board.

2. Replace board. See page 24.

308801 17