Setup

![]() WARNING

WARNING

If you supply your own hoses and spray gun, be sure the hoses are electrically conductive, that the gun has a tip guard, and that each part is rated for at least 3000 psi (210 bar, 21 MPa) Working Pres- sure. This is to reduce the risk of serious injury caused by static sparking, fluid injection or over– pressurization and rupture of the hose or gun.

![]() CAUTION

CAUTION

To avoid damaging the pressure control, which may result in poor equipment performance and compo- nent damage, follow these precautions:

DDo not allow material to freeze in sprayer.

DUse nylon spray hose at least 50 ft (15 m) long.

DDo not use wire braid hose.

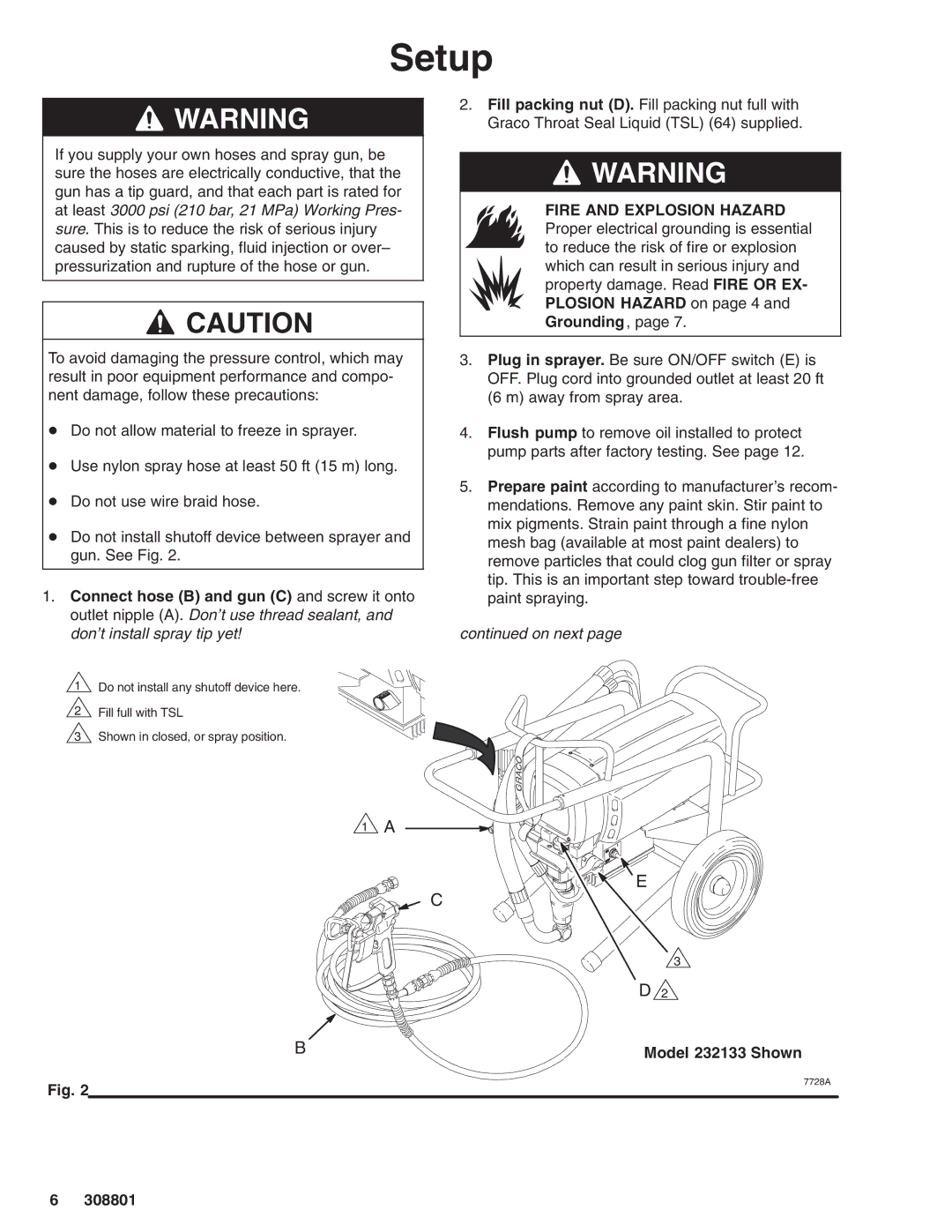

DDo not install shutoff device between sprayer and gun. See Fig. 2.

1.Connect hose (B) and gun (C) and screw it onto outlet nipple (A). Don’t use thread sealant, and don’t install spray tip yet!

2.Fill packing nut (D). Fill packing nut full with Graco Throat Seal Liquid (TSL) (64) supplied.

![]() WARNING

WARNING

FIRE AND EXPLOSION HAZARD Proper electrical grounding is essential to reduce the risk of fire or explosion which can result in serious injury and property damage. Read FIRE OR EX- PLOSION HAZARD on page 4 and Grounding , page 7.

3.Plug in sprayer. Be sure ON/OFF switch (E) is OFF. Plug cord into grounded outlet at least 20 ft (6 m) away from spray area.

4.Flush pump to remove oil installed to protect pump parts after factory testing. See page 12.

5.Prepare paint according to manufacturer’s recom- mendations. Remove any paint skin. Stir paint to mix pigments. Strain paint through a fine nylon mesh bag (available at most paint dealers) to remove particles that could clog gun filter or spray tip. This is an important step toward

continued on next page

1 Do not install any shutoff device here.

2Fill full with TSL

3 Shown in closed, or spray position.

1 A

E

C

3

D 2

B | Model 232133 Shown |

Fig. 2

7728A

6308801