Motor Brushes

NOTE: Replace brushes when worn to about 12.5 mm (0.5 in.). Always check both brushes. Brush Repair Kit 236967 is available for motor brush repair.

NOTE: Replacement brushes may last only half as long as the original ones. To maximize brush life, break in new brushes by operating the sprayer with no load as instructed in this procedure.

NOTE: To minimize down time, and for best sprayer performance, check motor brushes and clean trans- ducer (see page 28) whenever pump is repacked.

![]() WARNING

WARNING

INJECTION HAZARD

To reduce the risk of serious injury, when instructed to relieve pressure, follow the Pressure Relief Procedure on page 8.

1.Unplug sprayer.

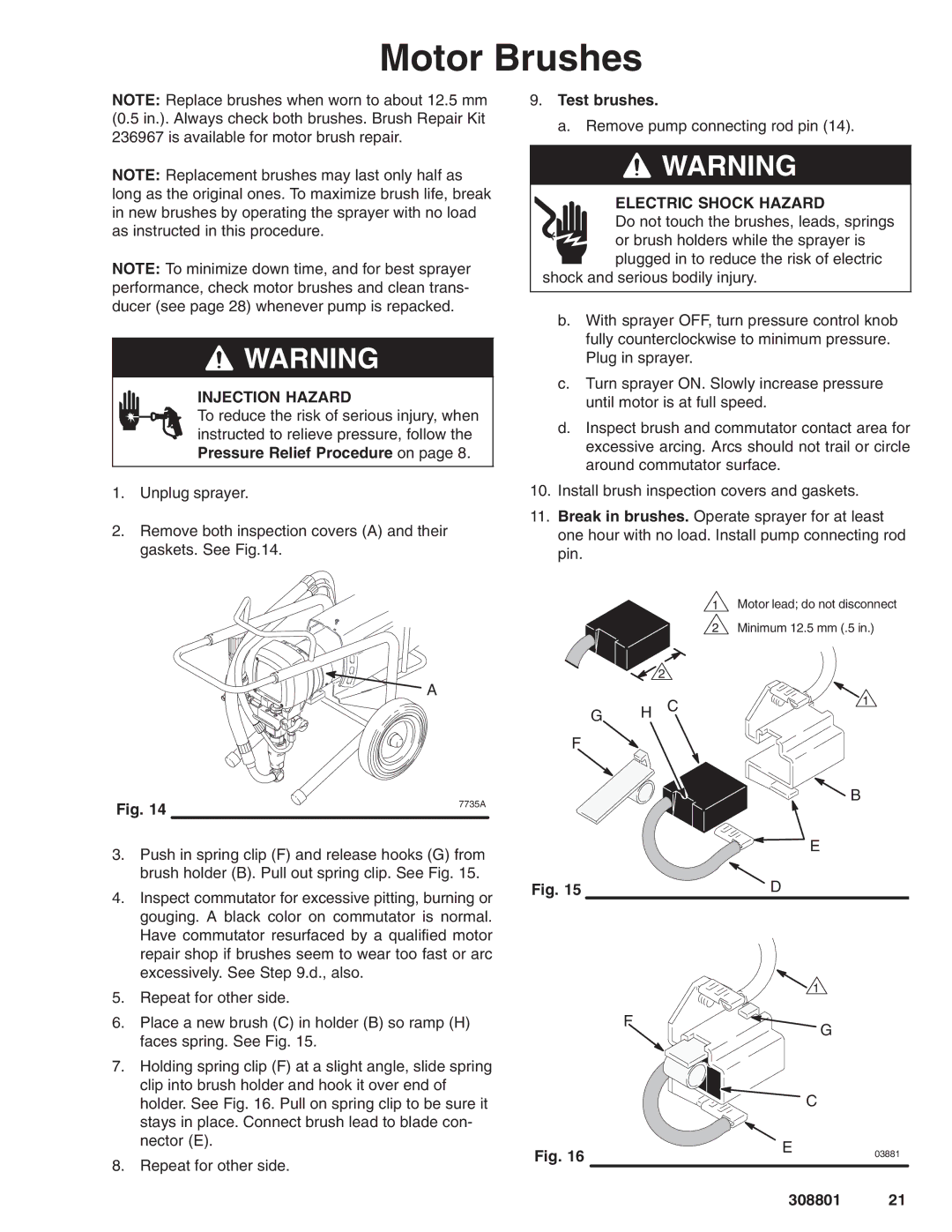

2.Remove both inspection covers (A) and their gaskets. See Fig.14.

A

Fig. 14 | 7735A |

|

3.Push in spring clip (F) and release hooks (G) from brush holder (B). Pull out spring clip. See Fig. 15.

4.Inspect commutator for excessive pitting, burning or gouging. A black color on commutator is normal. Have commutator resurfaced by a qualified motor repair shop if brushes seem to wear too fast or arc excessively. See Step 9.d., also.

5.Repeat for other side.

6.Place a new brush (C) in holder (B) so ramp (H) faces spring. See Fig. 15.

7.Holding spring clip (F) at a slight angle, slide spring clip into brush holder and hook it over end of holder. See Fig. 16. Pull on spring clip to be sure it stays in place. Connect brush lead to blade con- nector (E).

8.Repeat for other side.

9.Test brushes.

a. Remove pump connecting rod pin (14).

![]() WARNING

WARNING

ELECTRIC SHOCK HAZARD

Do not touch the brushes, leads, springs or brush holders while the sprayer is plugged in to reduce the risk of electric

shock and serious bodily injury.

b.With sprayer OFF, turn pressure control knob fully counterclockwise to minimum pressure. Plug in sprayer.

c.Turn sprayer ON. Slowly increase pressure until motor is at full speed.

d.Inspect brush and commutator contact area for excessive arcing. Arcs should not trail or circle around commutator surface.

10.Install brush inspection covers and gaskets.

11.Break in brushes. Operate sprayer for at least one hour with no load. Install pump connecting rod pin.

1Motor lead; do not disconnect

2Minimum 12.5 mm (.5 in.)

|

| 2 |

|

| H | C | 1 |

G |

| ||

|

| ||

F |

|

|

|

|

|

| B |

|

|

| E |

Fig. 15 |

|

| D |

|

| 1 |

|

| F | G |

|

|

|

| |

|

| C |

|

Fig. 16 |

| E | 03881 |

|

|

| |

|

| 308801 | 21 |