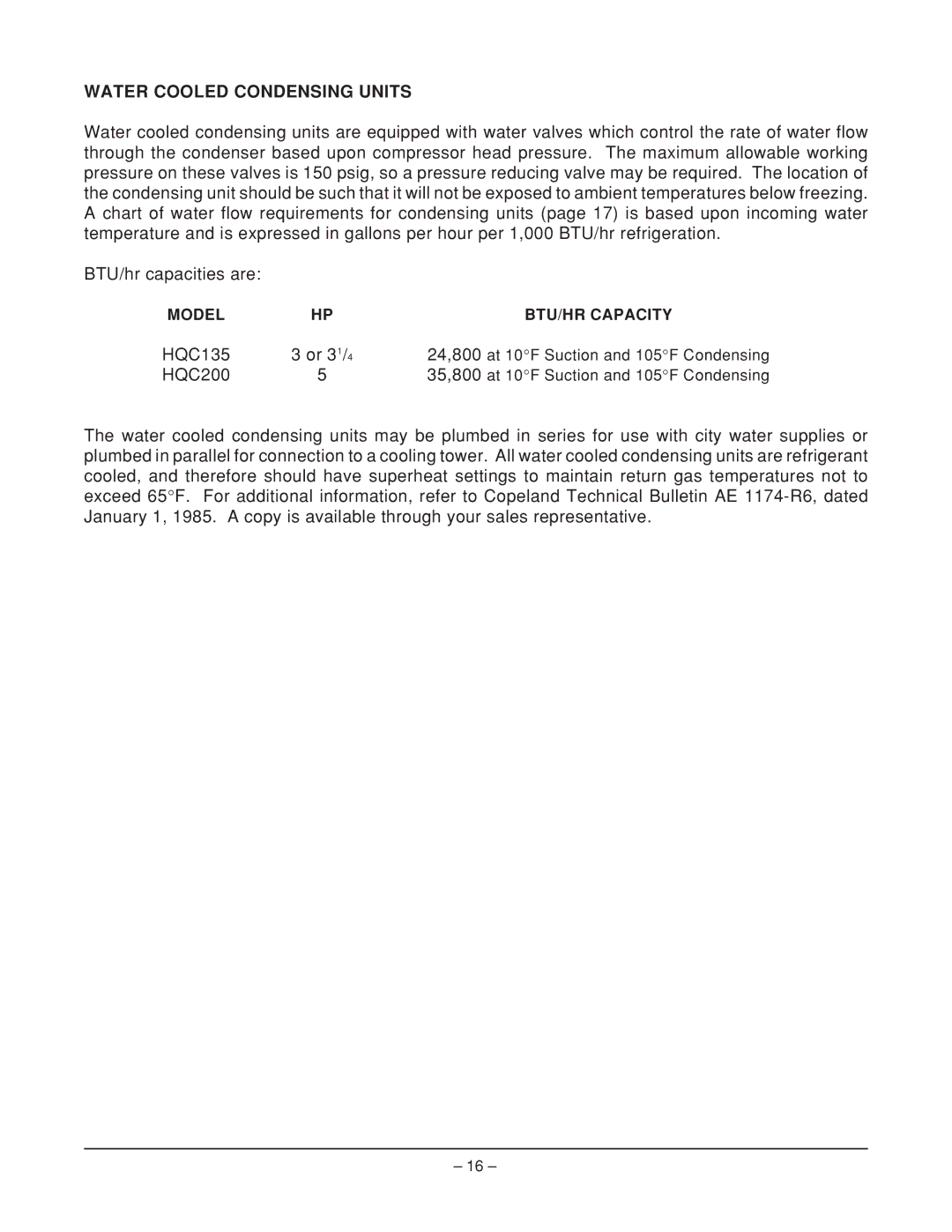

HQC200, ML-124070, ML-124069, HQC135 specifications

Hobart, a name synonymous with quality and innovation in food preparation equipment, boasts a diverse line of products designed for the industrial kitchen. Among their offerings are the HQC135, ML-124069, ML-124070, and HQC200, each engineered to meet the demanding needs of a commercial kitchen.The HQC135 is a dynamic countertop food processor that excels in versatility and efficiency. Designed for both small and large-scale operations, it features a powerful motor capable of handling various food items, from fresh vegetables to nuts and meats. Its precision cutting blades are crafted from high-quality stainless steel, ensuring durability and optimal performance. The intuitive control panel allows users to adjust settings for speed and time, making it facile to achieve the desired texture and consistency.

Next, the ML-124069 and ML-124070 are collaborative models specializing in food storage solutions. These models are characterized by their robust construction, designed to withstand the rigors of daily use in commercial kitchens. Both models come equipped with advanced temperature control systems, ensuring that perishable goods are maintained at optimal conditions. Their user-friendly interfaces include digital displays that provide real-time monitoring, allowing chefs to manage inventory efficiently and safely.

The HQC200 stands out in Hobart's lineup as an exemplary mixer with high-capacity capabilities suited for large batch production. This model integrates cutting-edge technology, including a planetary mixing mechanism that ensures thorough mixing and blending of ingredients. Its ergonomic design includes a tilt-back head for easy access to the mixing bowl and a variety of available attachments to accommodate different mixing requirements—from kneading dough to whipping cream. The HQC200 is also equipped with a safety interlock system, ensuring safe operation at all times.

Collectively, these models reflect Hobart's commitment to quality, innovation, and ease of use, making them essential components for any commercial kitchen. The emphasis on user-friendly interfaces, advanced technology, and superior materials not only enhances efficiency but also delivers excellent results, meeting the rigorous demands of food service professionals. Whether you require food processing, storage, or mixing solutions, Hobart's range provides the functionality and reliability that helps to elevate culinary operations to new heights.