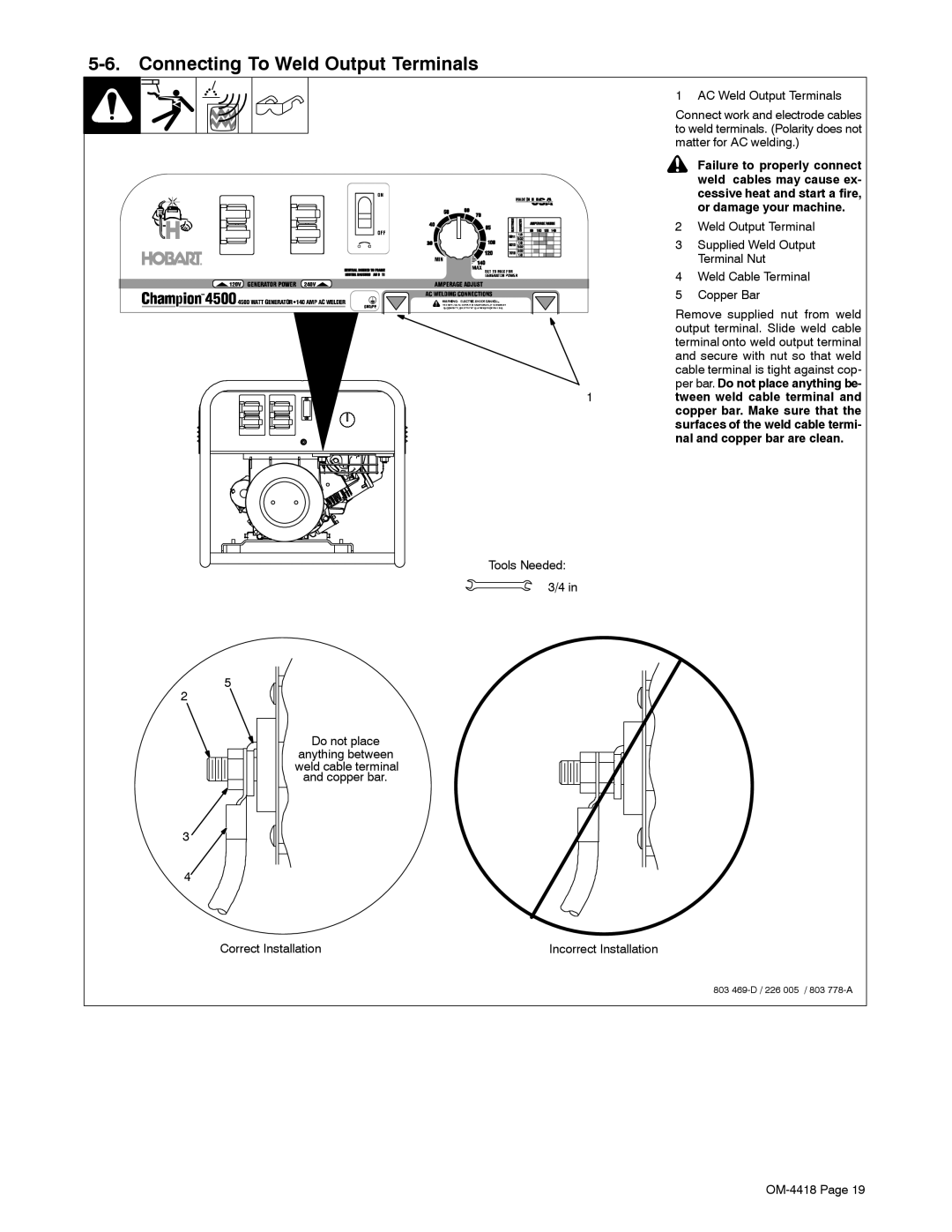

5-6. Connecting To Weld Output Terminals

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1 | AC Weld Output Terminals |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Connect work and electrode cables | |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| to weld terminals. (Polarity does not | |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| matter for AC welding.) | |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ! | Failure to properly connect |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| weld cables may cause ex- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| cessive heat and start a fire, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| or damage your machine. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 2 | Weld Output Terminal |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 3 | Supplied Weld Output |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Terminal Nut |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 4 | Weld Cable Terminal |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 5 | Copper Bar |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Remove supplied nut from weld | |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| output terminal. Slide weld cable | |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| terminal onto weld output terminal | |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| and secure with nut so that weld | |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| cable terminal is tight against cop- | |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| per bar. Do not place anything be- | |

1 | tween weld cable terminal and | ||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| copper bar. Make sure that the | |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| surfaces of the weld cable termi- | |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| nal and copper bar are clean. | |

Tools Needed: 3/4 in

5

2

Do not place anything between weld cable terminal and copper bar.

3

4

Correct Installation | Incorrect Installation |

803