.A complete Parts List is available at www.MillerWelds.com

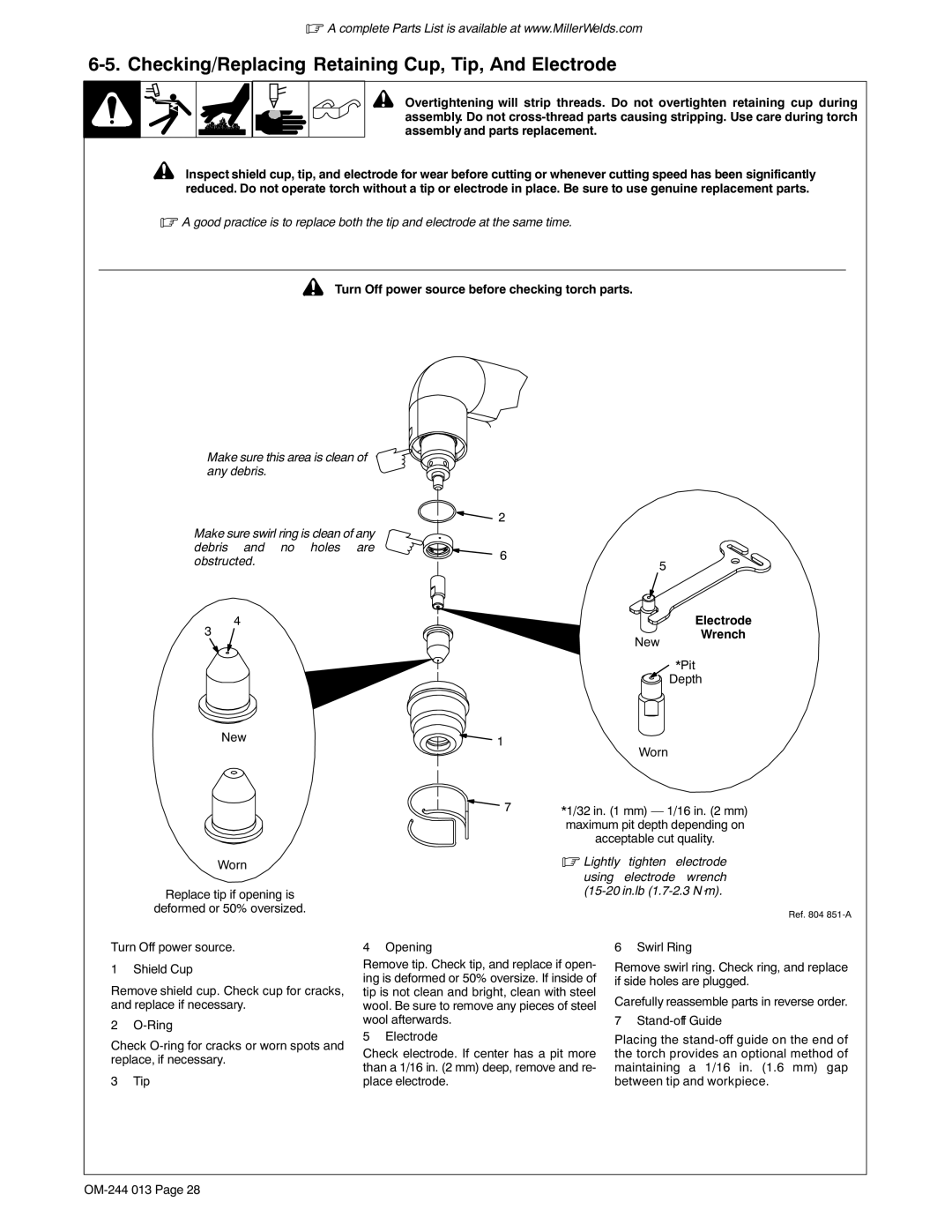

6-5. Checking/Replacing Retaining Cup, Tip, And Electrode

![]() ! Overtightening will strip threads. Do not overtighten retaining cup during assembly. Do not

! Overtightening will strip threads. Do not overtighten retaining cup during assembly. Do not

![]() ! Inspect shield cup, tip, and electrode for wear before cutting or whenever cutting speed has been significantly reduced. Do not operate torch without a tip or electrode in place. Be sure to use genuine replacement parts.

! Inspect shield cup, tip, and electrode for wear before cutting or whenever cutting speed has been significantly reduced. Do not operate torch without a tip or electrode in place. Be sure to use genuine replacement parts.

.A good practice is to replace both the tip and electrode at the same time.

! Turn Off power source before checking torch parts.

! Turn Off power source before checking torch parts.

Make sure this area is clean of any debris.

Make sure swirl ring is clean of any debris and no holes are obstructed.

![]() 2

2

6

5

4

3

New

Electrode Wrench

New

*Pit Depth

![]() 1

1

Worn

7*1/32 in. (1 mm) — 1/16 in. (2 mm) maximum pit depth depending on acceptable cut quality.

Worn

Replace tip if opening is

deformed or 50% oversized.

.Lightly tighten electrode using electrode wrench

Ref. 804

Turn Off power source.

1Shield Cup

Remove shield cup. Check cup for cracks, and replace if necessary.

2

Check

3Tip

4Opening

Remove tip. Check tip, and replace if open- ing is deformed or 50% oversize. If inside of tip is not clean and bright, clean with steel wool. Be sure to remove any pieces of steel wool afterwards.

5Electrode

Check electrode. If center has a pit more than a 1/16 in. (2 mm) deep, remove and re- place electrode.

6Swirl Ring

Remove swirl ring. Check ring, and replace if side holes are plugged.

Carefully reassemble parts in reverse order.

7

Placing the