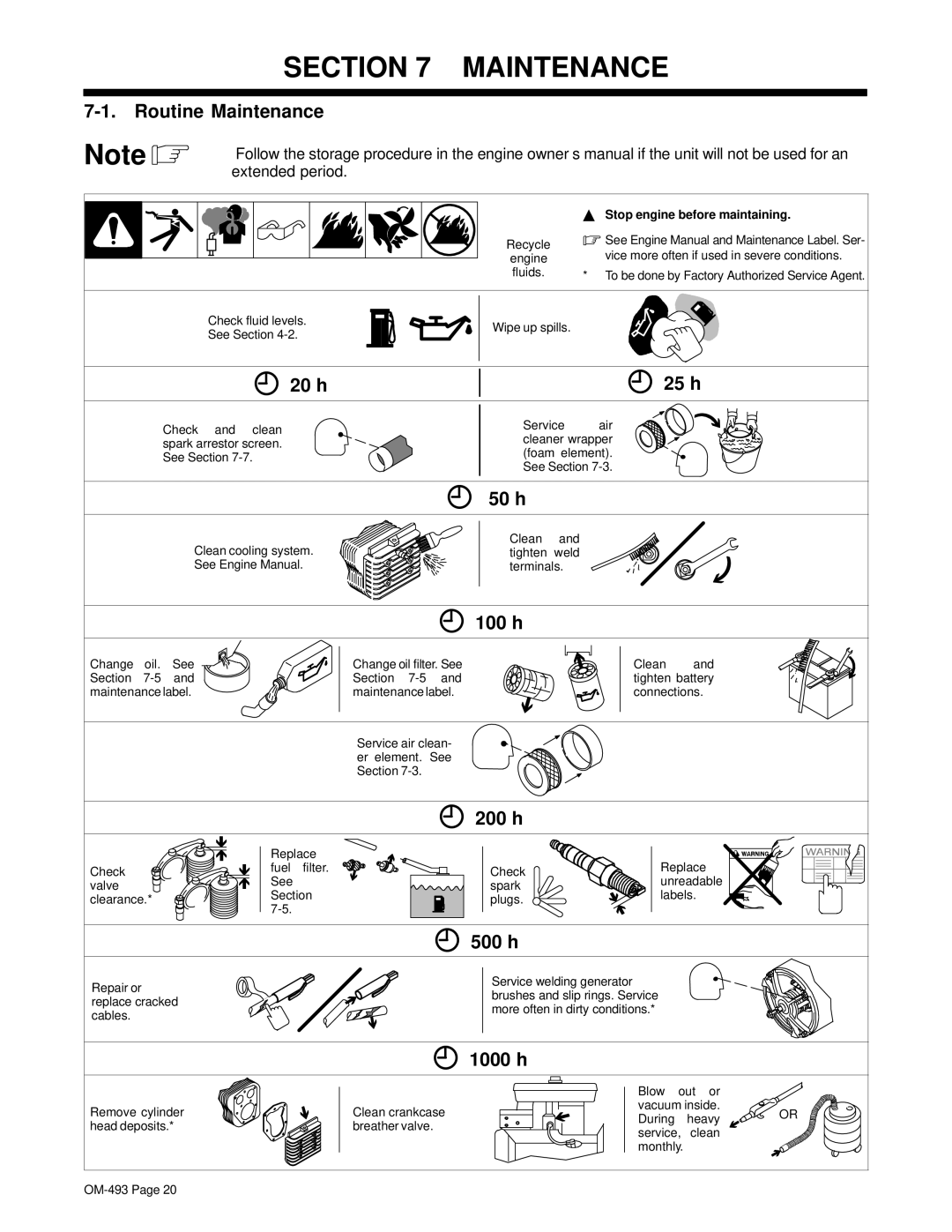

SECTION 7 – MAINTENANCE

7-1. Routine Maintenance

Note | Follow the storage procedure in the engine owner’s manual if the unit will not be used for an | |

| extended period. |

|

|

| Y Stop engine before maintaining. |

| Recycle | . See Engine Manual and Maintenance Label. Ser- |

| engine | vice more often if used in severe conditions. |

| fluids. | * To be done by Factory Authorized Service Agent. |

Check fluid levels. See Section

Wipe up spills.

20 h

20 h

25 h

25 h

Check and clean spark arrestor screen. See Section

Service air cleaner wrapper (foam element). See Section

50 h

Clean cooling system. See Engine Manual.

Clean and tighten weld terminals.

100 h

100 h

Change oil. See Section

Change oil filter. See | Clean | and |

Section | tighten battery | |

maintenance label. | connections. | |

Service air clean- er element. See Section

200 h

200 h

| Replace | |

Check | fuel filter. | |

See | ||

valve | ||

Section | ||

clearance.* | ||

|

Check spark plugs.

Replace |

unreadable |

labels. |

500 h

500 h

Repair or replace cracked cables.

Service welding generator brushes and slip rings. Service more often in dirty conditions.*

1000 h

1000 h

|

| Blow | out or |

| |

Remove cylinder | Clean crankcase | vacuum inside. | OR | ||

During | heavy | ||||

head deposits.* | breather valve. |

| |||

service, clean |

| ||||

|

|

| |||

monthly.