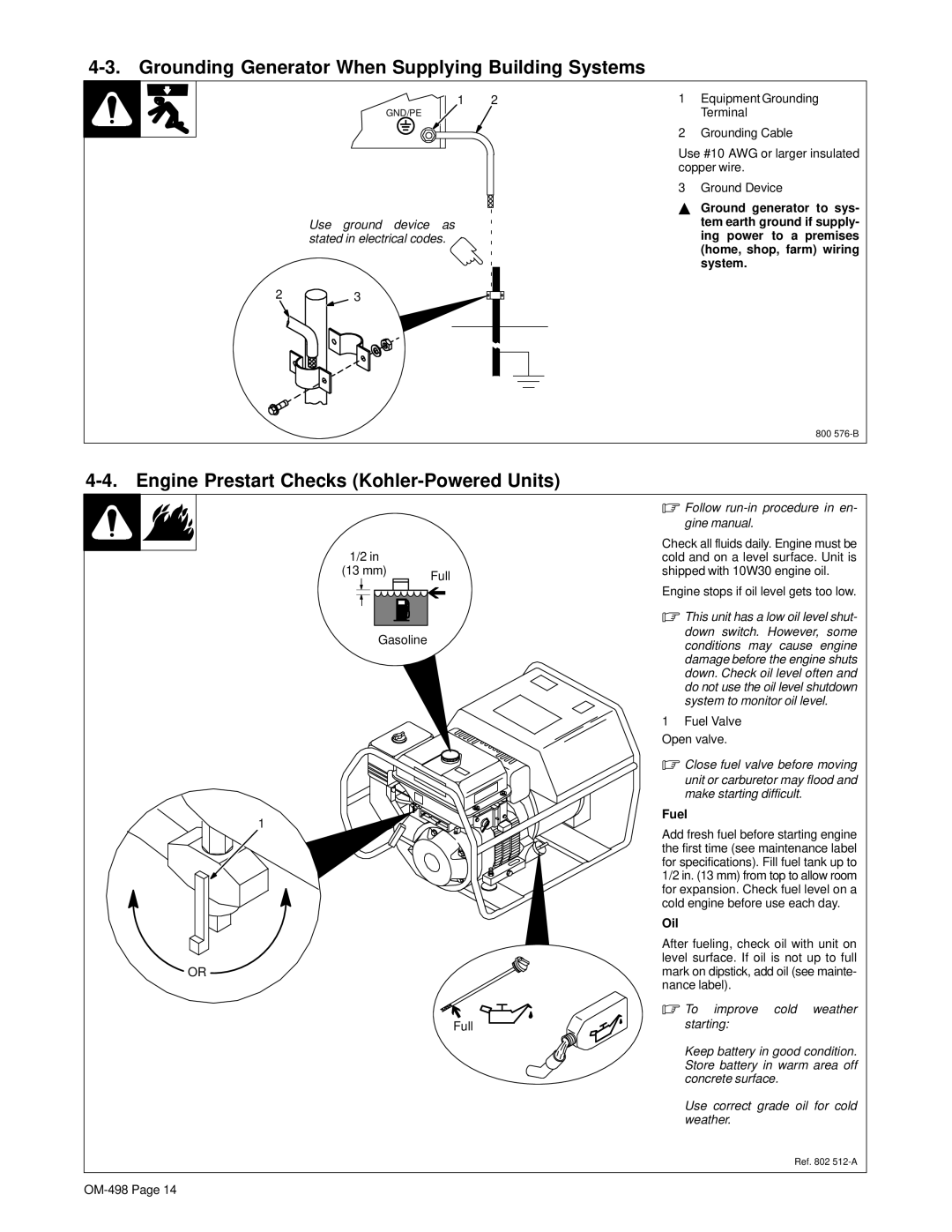

4-3. Grounding Generator When Supplying Building Systems

1 2

GND/PE

Use ground device as stated in electrical codes.

23

1Equipment Grounding Terminal

2Grounding Cable

Use #10 AWG or larger insulated copper wire.

3 Ground Device

YGround generator to sys- tem earth ground if supply- ing power to a premises (home, shop, farm) wiring system.

800

|

|

|

| |

|

| . Follow | ||

|

|

| gine manual. |

|

1/2 in |

| Check all fluids daily. Engine must be | ||

| cold and on a level surface. Unit is | |||

(13 mm) | Full | shipped with 10W30 engine oil. | ||

|

|

|

| |

|

| Engine stops if oil level gets too low. | ||

|

| . This unit has a low oil level shut- | ||

Gasoline |

|

| down switch. However, | some |

|

| conditions may cause | engine | |

|

|

| ||

|

|

| damage before the engine shuts | |

|

|

| down. Check oil level often and | |

|

|

| do not use the oil level shutdown | |

|

|

| system to monitor oil level. | |

|

| 1 | Fuel Valve |

|

|

| Open valve. |

| |

|

| . Close fuel valve before moving | ||

|

|

| unit or carburetor may flood and | |

|

|

| make starting difficult. |

|

1 |

| Fuel |

| |

| Add fresh fuel before starting engine | |||

|

| |||

|

| the first time (see maintenance label | ||

|

| for specifications). Fill fuel tank up to | ||

|

| 1/2 in. (13 mm) from top to allow room | ||

|

| for expansion. Check fuel level on a | ||

|

| cold engine before use each day. | ||

|

| Oil |

|

|

|

| After fueling, check oil with unit on | ||

|

| level surface. If oil is not up to full | ||

OR |

| mark on dipstick, add oil (see mainte- | ||

|

| nance label). |

| |

|

| . To improve cold weather | ||

| Full |

| starting: |

|

|

|

| Keep battery in good condition. | |

|

|

| Store battery in warm area off | |

|

|

| concrete surface. |

|

|

|

| Use correct grade oil for cold | |

|

|

| weather. |

|

|

|

| Ref. 802 | |

|

|

|

| |