|

| R4795A | |

|

| OPERATION • TROUBLESHOOTING | |

|

| Operation | |

|

|

| |

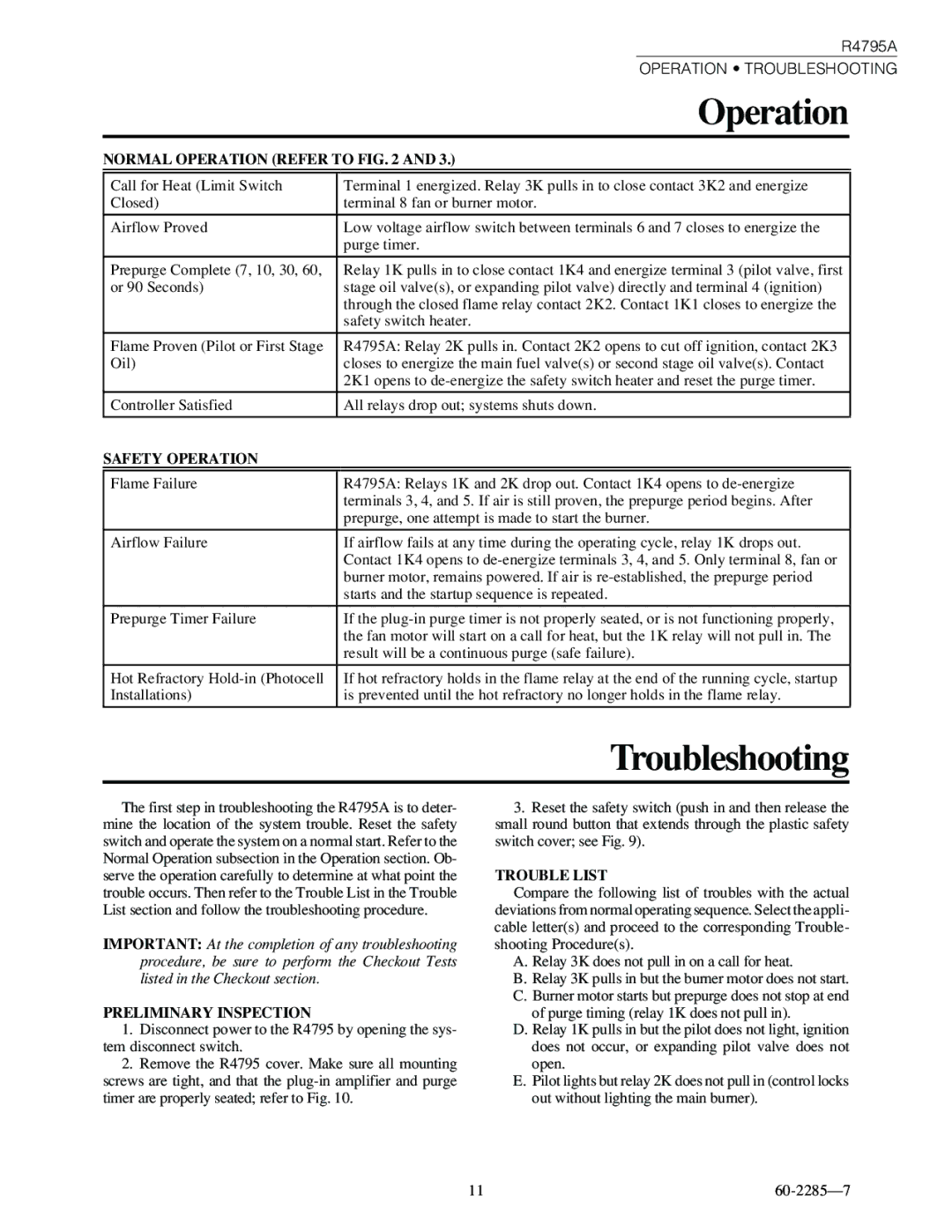

NORMAL OPERATION (REFER TO FIG. 2 AND 3.) |

| ||

|

| ||

Call for Heat (Limit Switch | Terminal 1 energized. Relay 3K pulls in to close contact 3K2 and energize |

| |

Closed) | terminal 8 fan or burner motor. |

| |

|

|

| |

Airflow Proved | Low voltage airflow switch between terminals 6 and 7 closes to energize the |

| |

| purge timer. |

| |

|

|

| |

Prepurge Complete (7, 10, 30, 60, | Relay 1K pulls in to close contact 1K4 and energize terminal 3 (pilot valve, first |

| |

or 90 Seconds) | stage oil valve(s), or expanding pilot valve) directly and terminal 4 (ignition) |

| |

| through the closed flame relay contact 2K2. Contact 1K1 closes to energize the |

| |

| safety switch heater. |

| |

|

|

| |

Flame Proven (Pilot or First Stage | R4795A: Relay 2K pulls in. Contact 2K2 opens to cut off ignition, contact 2K3 |

| |

Oil) | closes to energize the main fuel valve(s) or second stage oil valve(s). Contact |

| |

| 2K1 opens to |

| |

|

|

| |

Controller Satisfied | All relays drop out; systems shuts down. |

| |

|

|

|

|

SAFETY OPERATION |

|

|

|

|

| ||

Flame Failure | R4795A: Relays 1K and 2K drop out. Contact 1K4 opens to |

| |

| terminals 3, 4, and 5. If air is still proven, the prepurge period begins. After |

| |

| prepurge, one attempt is made to start the burner. |

| |

|

|

| |

Airflow Failure | If airflow fails at any time during the operating cycle, relay 1K drops out. |

| |

| Contact 1K4 opens to |

| |

| burner motor, remains powered. If air is |

| |

| starts and the startup sequence is repeated. |

| |

|

|

| |

Prepurge Timer Failure | If the |

| |

| the fan motor will start on a call for heat, but the 1K relay will not pull in. The |

| |

| result will be a continuous purge (safe failure). |

| |

|

|

| |

Hot Refractory | If hot refractory holds in the flame relay at the end of the running cycle, startup |

| |

Installations) | is prevented until the hot refractory no longer holds in the flame relay. |

| |

|

|

|

|

Troubleshooting

The first step in troubleshooting the R4795A is to deter- mine the location of the system trouble. Reset the safety switch and operate the system on a normal start. Refer to the Normal Operation subsection in the Operation section. Ob- serve the operation carefully to determine at what point the trouble occurs. Then refer to the Trouble List in the Trouble List section and follow the troubleshooting procedure.

IMPORTANT: At the completion of any troubleshooting procedure, be sure to perform the Checkout Tests listed in the Checkout section.

PRELIMINARY INSPECTION

1.Disconnect power to the R4795 by opening the sys- tem disconnect switch.

2.Remove the R4795 cover. Make sure all mounting screws are tight, and that the

3.Reset the safety switch (push in and then release the small round button that extends through the plastic safety switch cover; see Fig. 9).

TROUBLE LIST

Compare the following list of troubles with the actual deviations from normal operating sequence. Select the appli- cable letter(s) and proceed to the corresponding Trouble- shooting Procedure(s).

A. Relay 3K does not pull in on a call for heat.

B.Relay 3K pulls in but the burner motor does not start.

C.Burner motor starts but prepurge does not stop at end of purge timing (relay 1K does not pull in).

D.Relay 1K pulls in but the pilot does not light, ignition does not occur, or expanding pilot valve does not open.

E.Pilot lights but relay 2K does not pull in (control locks out without lighting the main burner).

11 |