R4795A

INSTALLATION

Installation

![]() CAUTION

CAUTION

1.Installer must be a trained, experienced, flame safeguard control service technician.

2.Disconnect power supply before beginning in- stallation to prevent electrical shock and equip- ment damage.

3.All wiring must comply with applicable local electrical codes, ordinances, and regulations.

4.Voltage and frequency of the power supply connected to this control must agree with those marked on the device.

5.Loads connected to the control terminals must not exceed those listed in the Specifications section.

6.All external timers must be Listed or Compo- nent Recognized by authorities having jurisdic- tion for the specific purpose for which they are used.

7.Some authorities having jurisdiction prohibit the wiring of any limit or operating contacts in series with the main fuel valve(s).

8.Perform all required checkout tests after instal- lation is complete.

Follow the burner manufacturer’s instructions, if sup- plied. Otherwise proceed as follows.

![]() CAUTION

CAUTION

Ultraviolet sensing tubes have a life expectancy of 40,000 hours of continuous use within the ambient temperature and voltage ratings. Worn out ultra- violet sensing tubes can result in failure of the sensing tube to properly discriminate between flame conditions.

For systems using R4795A with R7290 Amplifiers, use C7027, C7035 and C7044 Flame Detectors only on burners that cycle On and Off at least once every 24 hours. Appli- ances with burners that remain on for 24 hours continuously or longer should use the C7012E Flame Detector with the R7247C Amplifier or the C7076A Flame Detector with the R7476A Amplifier as the ultraviolet flame detection system.

LOCATION

Temperature

Install the R4795A where the surrounding temperatures remain within the Ambient Operating Temperature Ratings listed in the Specifications section.

Humidity

Install the R4795A where the relative humidity never reaches the saturation point. Condensation of moisture on the R4795A may cause enough leakage to short the flame signal to ground and prevent the burner from starting.

Vibration

Do not install the R4795A where it could be subject to excessive vibration. Vibration shortens the life of the elec- tronic and mechanical components.

Weather

The R4795A is not designed to be weathertight. If it is installed outdoors, use a suitable weathertight enclosure.

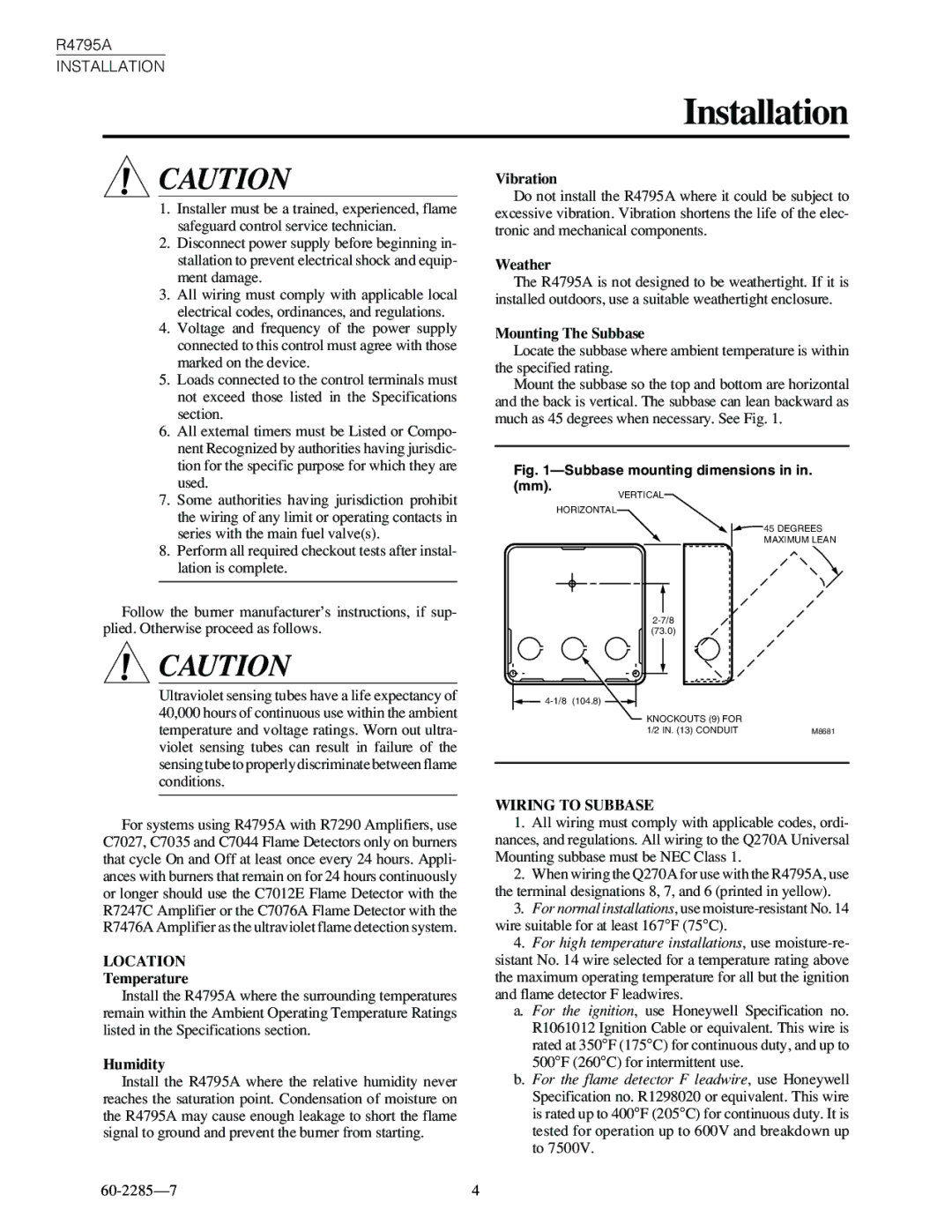

Mounting The Subbase

Locate the subbase where ambient temperature is within the specified rating.

Mount the subbase so the top and bottom are horizontal and the back is vertical. The subbase can lean backward as much as 45 degrees when necessary. See Fig. 1.

Fig. 1—Subbase mounting dimensions in in. (mm).

VERTICAL

HORIZONTAL

45 DEGREES MAXIMUM LEAN

(73.0)

![]()

KNOCKOUTS (9) FOR |

|

1/2 IN. (13) CONDUIT | M8681 |

WIRING TO SUBBASE

1.All wiring must comply with applicable codes, ordi- nances, and regulations. All wiring to the Q270A Universal Mounting subbase must be NEC Class 1.

2.When wiring the Q270A for use with the R4795A, use the terminal designations 8, 7, and 6 (printed in yellow).

3.For normal installations, use

4.For high temperature installations, use

a. For the ignition, use Honeywell Specification no. R1061012 Ignition Cable or equivalent. This wire is rated at 350°F (175°C) for continuous duty, and up to 500°F (260°C) for intermittent use.

b. For the flame detector F leadwire, use Honeywell Specification no. R1298020 or equivalent. This wire is rated up to 400°F (205°C) for continuous duty. It is tested for operation up to 600V and breakdown up to 7500V.

4 |