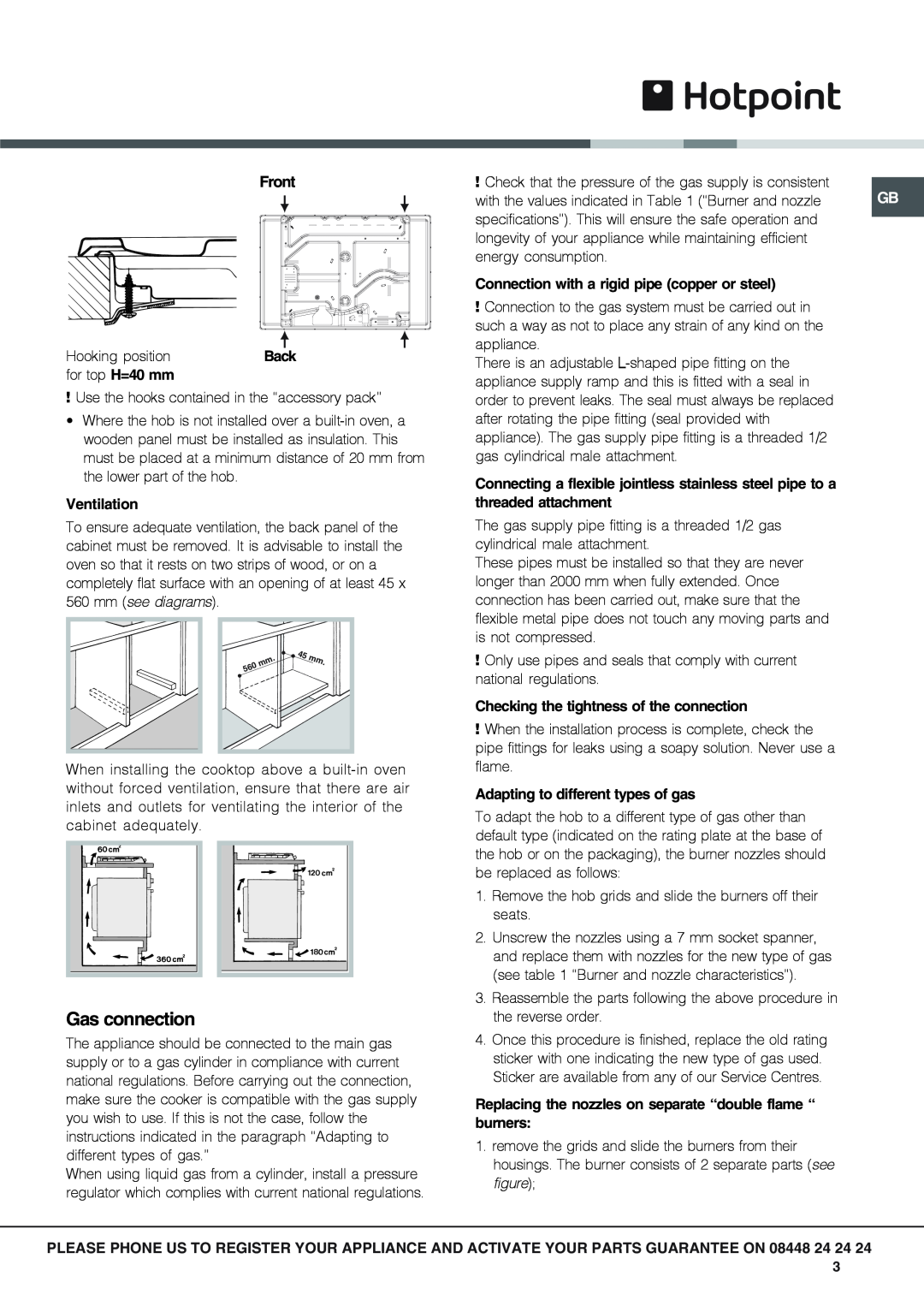

Hooking position for top H=40 mm

Front |

Back |

!Check that the pressure of the gas supply is consistent

with the values indicated in Table 1 (“Burner and nozzle | GB |

specifications”). This will ensure the safe operation and |

|

longevity of your appliance while maintaining efficient |

|

energy consumption. |

|

Connection with a rigid pipe (copper or steel)

! Connection to the gas system must be carried out in |

such a way as not to place any strain of any kind on the |

appliance. |

There is an adjustable |

appliance supply ramp and this is fitted with a seal in |

!Use the hooks contained in the “accessory pack”

•Where the hob is not installed over a

Ventilation

To ensure adequate ventilation, the back panel of the cabinet must be removed. It is advisable to install the oven so that it rests on two strips of wood, or on a completely flat surface with an opening of at least 45 x 560 mm (see diagrams).

. | 45 | m | m |

|

m |

|

| . | |

m |

|

|

| |

560 |

|

|

|

|

When installing the cooktop above a

Gas connection

The appliance should be connected to the main gas supply or to a gas cylinder in compliance with current national regulations. Before carrying out the connection, make sure the cooker is compatible with the gas supply you wish to use. If this is not the case, follow the instructions indicated in the paragraph “Adapting to different types of gas.”

When using liquid gas from a cylinder, install a pressure regulator which complies with current national regulations.

order to prevent leaks. The seal must always be replaced |

after rotating the pipe fitting (seal provided with |

appliance). The gas supply pipe fitting is a threaded 1/2 |

gas cylindrical male attachment. |

Connecting a flexible jointless stainless steel pipe to a threaded attachment

The gas supply pipe fitting is a threaded 1/2 gas cylindrical male attachment.

These pipes must be installed so that they are never longer than 2000 mm when fully extended. Once connection has been carried out, make sure that the flexible metal pipe does not touch any moving parts and is not compressed.

!Only use pipes and seals that comply with current national regulations.

Checking the tightness of the connection

!When the installation process is complete, check the pipe fittings for leaks using a soapy solution. Never use a flame.

Adapting to different types of gas

To adapt the hob to a different type of gas other than default type (indicated on the rating plate at the base of the hob or on the packaging), the burner nozzles should be replaced as follows:

1.Remove the hob grids and slide the burners off their seats.

2.Unscrew the nozzles using a 7 mm socket spanner, and replace them with nozzles for the new type of gas (see table 1 “Burner and nozzle characteristics”).

3.Reassemble the parts following the above procedure in the reverse order.

4.Once this procedure is finished, replace the old rating sticker with one indicating the new type of gas used. Sticker are available from any of our Service Centres.

Replacing the nozzles on separate “double flame “ burners:

1.remove the grids and slide the burners from their housings. The burner consists of 2 separate parts (see figure);

PLEASE PHONE US TO REGISTER YOUR APPLIANCE AND ACTIVATE YOUR PARTS GUARANTEE ON 08448 24 24 24

3