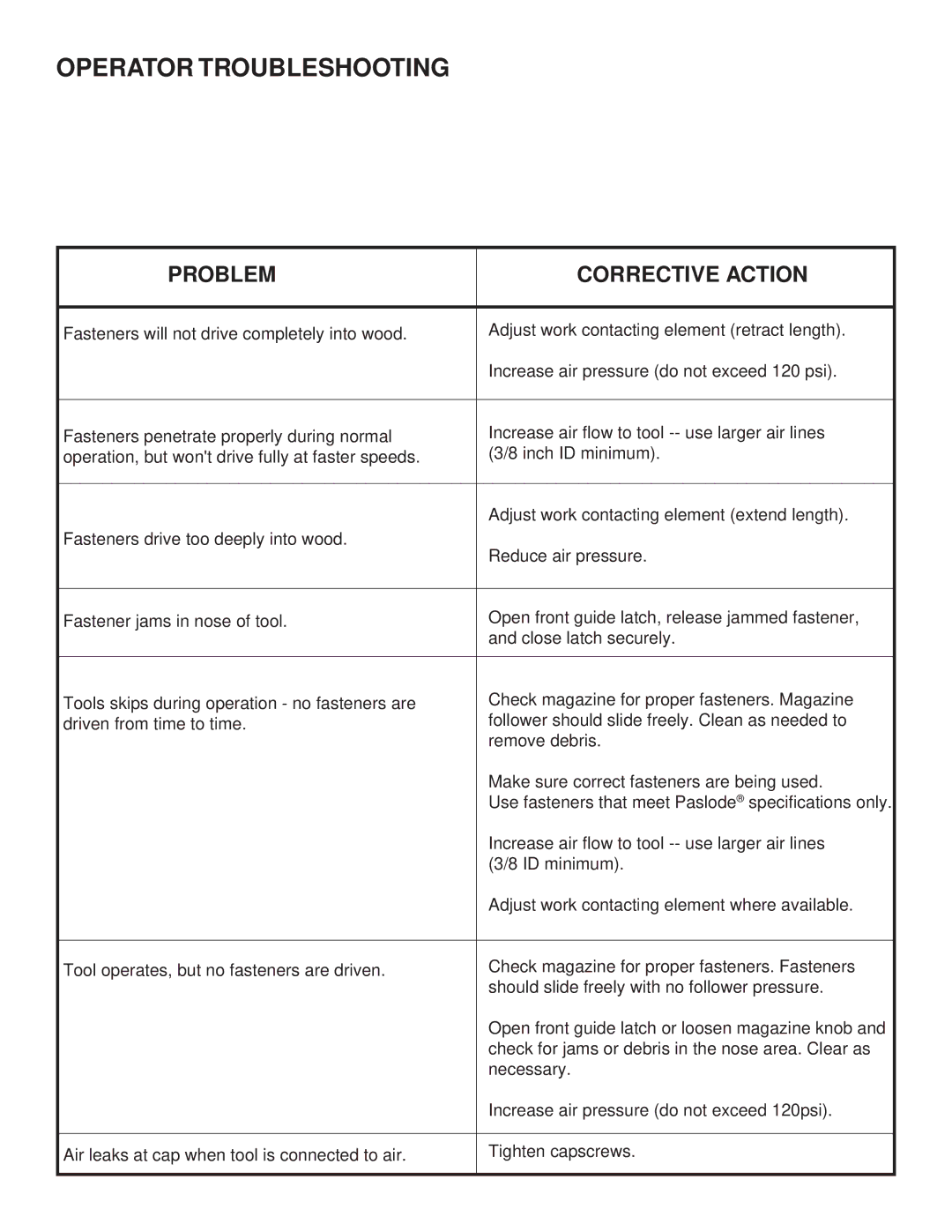

OPERATOR TROUBLESHOOTING

PROBLEM | CORRECTIVE ACTION |

|

|

Fasteners will not drive completely into wood. | Adjust work contacting element (retract length). |

| Increase air pressure (do not exceed 120 psi). |

|

|

Fasteners penetrate properly during normal | Increase air flow to tool |

operation, but won't drive fully at faster speeds. | (3/8 inch ID minimum). |

|

|

| Adjust work contacting element (extend length). |

Fasteners drive too deeply into wood. | Reduce air pressure. |

| |

|

|

Fastener jams in nose of tool. | Open front guide latch, release jammed fastener, |

| and close latch securely. |

|

|

Tools skips during operation - no fasteners are | Check magazine for proper fasteners. Magazine |

driven from time to time. | follower should slide freely. Clean as needed to |

| remove debris. |

| Make sure correct fasteners are being used. |

| Use fasteners that meet Paslode® specifications only. |

| Increase air flow to tool |

| (3/8 ID minimum). |

| Adjust work contacting element where available. |

|

|

Tool operates, but no fasteners are driven. | Check magazine for proper fasteners. Fasteners |

| should slide freely with no follower pressure. |

| Open front guide latch or loosen magazine knob and |

| check for jams or debris in the nose area. Clear as |

| necessary. |

| Increase air pressure (do not exceed 120psi). |

|

|

Air leaks at cap when tool is connected to air. | Tighten capscrews. |

|

|