AIR SYSTEMS

For

•Air hoses are not longer than 150 feet.

•The air system is lubricated regularly.

•A regular maintenance program is followed.

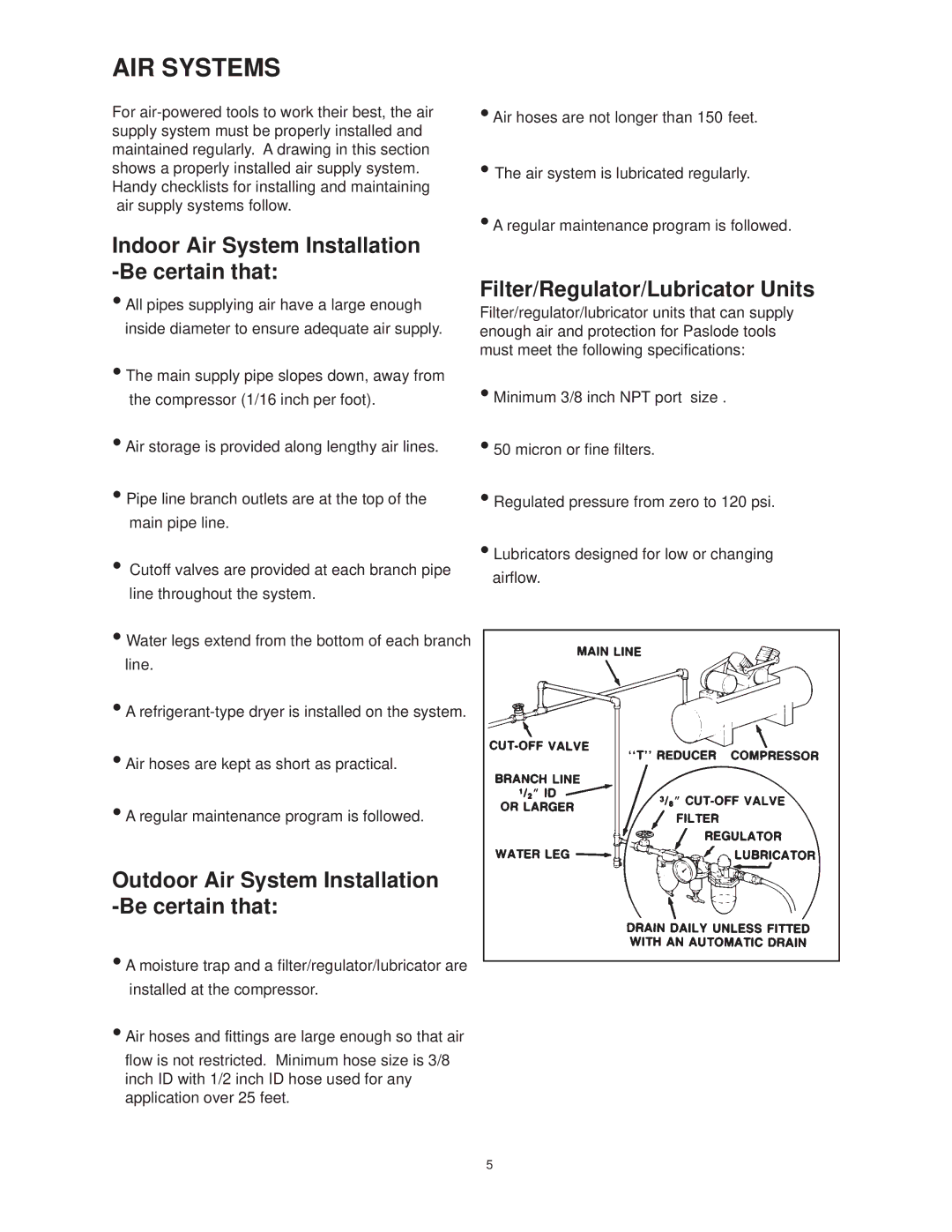

Indoor Air System Installation -Be certain that:

•All pipes supplying air have a large enough inside diameter to ensure adequate air supply.

•The main supply pipe slopes down, away from the compressor (1/16 inch per foot).

•Air storage is provided along lengthy air lines.

•Pipe line branch outlets are at the top of the main pipe line.

•Cutoff valves are provided at each branch pipe line throughout the system.

•Water legs extend from the bottom of each branch line.

•A

•Air hoses are kept as short as practical.

•A regular maintenance program is followed.

Outdoor Air System Installation

Filter/Regulator/Lubricator Units

Filter/regulator/lubricator units that can supply enough air and protection for Paslode tools must meet the following specifications:

•Minimum 3/8 inch NPT port size .

•50 micron or fine filters.

•Regulated pressure from zero to 120 psi.

•Lubricators designed for low or changing airflow.

•

•

A moisture trap and a filter/regulator/lubricator are

installed at the compressor.

Air hoses and fittings are large enough so that air

flow is not restricted. Minimum hose size is 3/8 inch ID with 1/2 inch ID hose used for any application over 25 feet.

5