TOOL OPERATION - continued

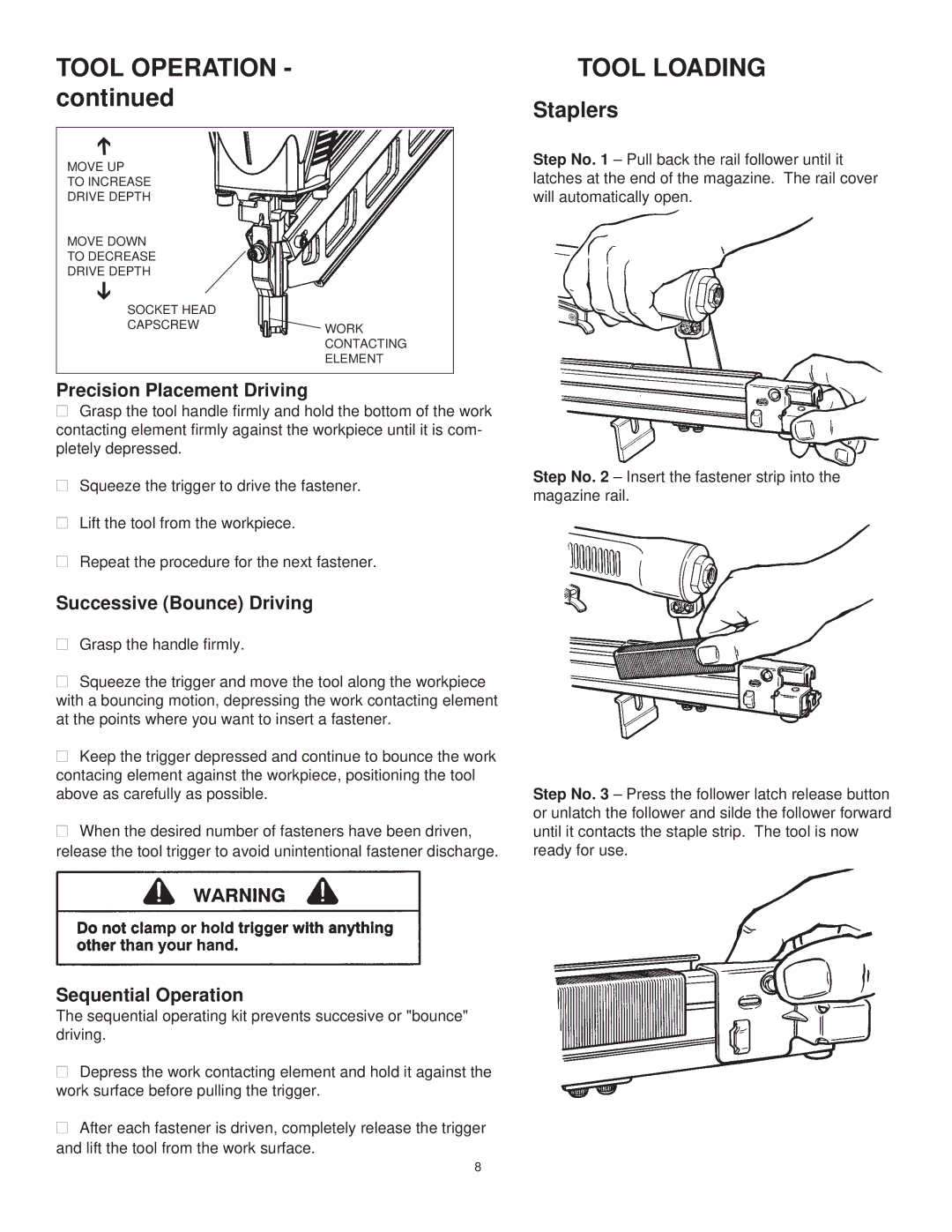

MOVE UP

TO INCREASE

DRIVE DEPTH

MOVE DOWN

TO DECREASE

DRIVE DEPTH

➔

SOCKET HEAD

CAPSCREWWORK

CONTACTING

ELEMENT

Precision Placement Driving

■Grasp the tool handle firmly and hold the bottom of the work contacting element firmly against the workpiece until it is com- pletely depressed.

■Squeeze the trigger to drive the fastener.

■Lift the tool from the workpiece.

■Repeat the procedure for the next fastener.

Successive (Bounce) Driving

■Grasp the handle firmly.

■Squeeze the trigger and move the tool along the workpiece with a bouncing motion, depressing the work contacting element at the points where you want to insert a fastener.

■Keep the trigger depressed and continue to bounce the work contacing element against the workpiece, positioning the tool above as carefully as possible.

■When the desired number of fasteners have been driven,

release the tool trigger to avoid unintentional fastener discharge.

TOOL LOADING

Staplers

Step No. 1 – Pull back the rail follower until it latches at the end of the magazine. The rail cover will automatically open.

Step No. 2 – Insert the fastener strip into the magazine rail.

Step No. 3 – Press the follower latch release button or unlatch the follower and silde the follower forward until it contacts the staple strip. The tool is now ready for use.

Sequential Operation

The sequential operating kit prevents succesive or "bounce" driving.

■Depress the work contacting element and hold it against the work surface before pulling the trigger.

■After each fastener is driven, completely release the trigger and lift the tool from the work surface.

8