Item | Description | Initial |

|

|

|

|

|

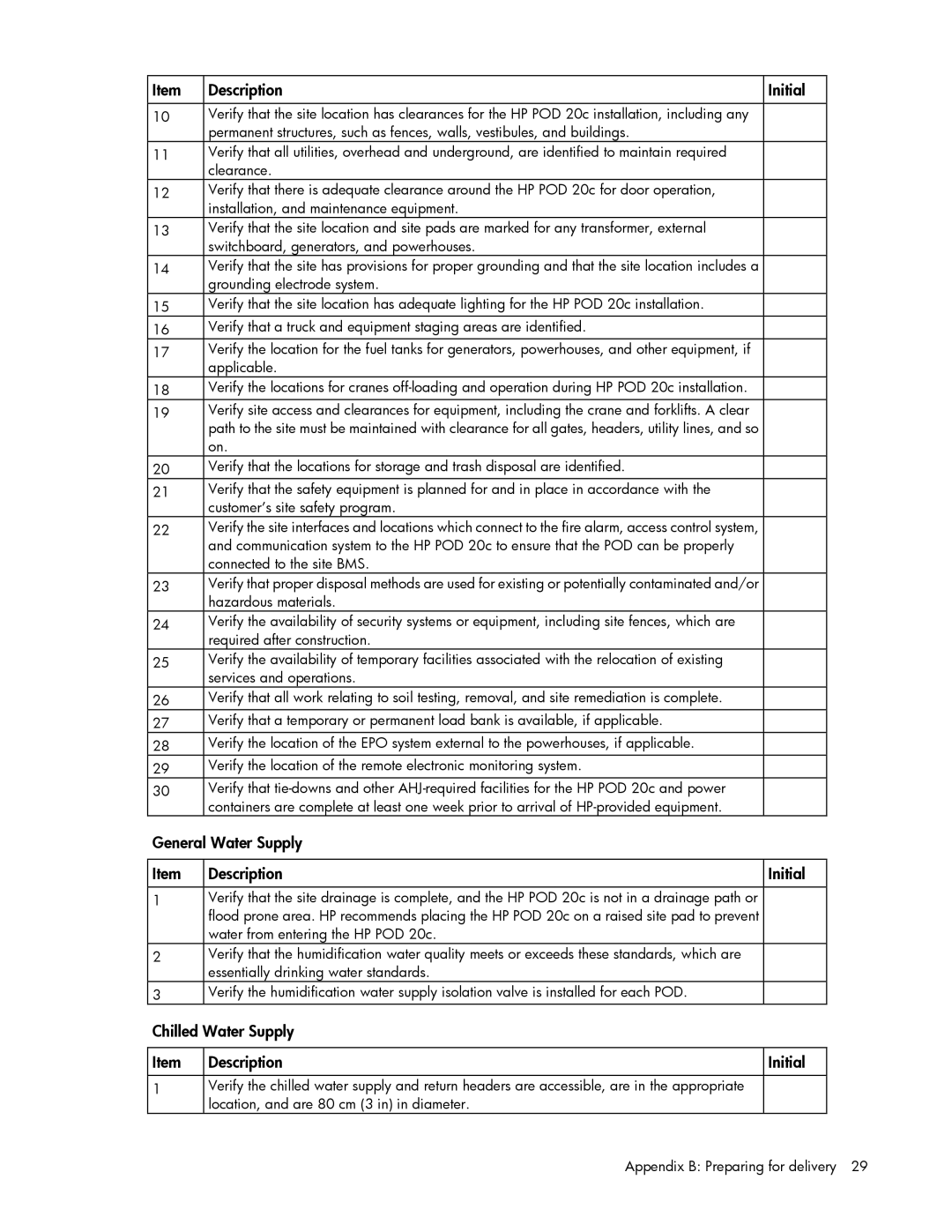

10 | Verify that the site location has clearances for the HP POD 20c installation, including any |

|

|

| permanent structures, such as fences, walls, vestibules, and buildings. |

|

|

11 | Verify that all utilities, overhead and underground, are identified to maintain required |

|

|

| clearance. |

|

|

12 | Verify that there is adequate clearance around the HP POD 20c for door operation, |

|

|

| installation, and maintenance equipment. |

|

|

13 | Verify that the site location and site pads are marked for any transformer, external |

|

|

| switchboard, generators, and powerhouses. |

|

|

14 | Verify that the site has provisions for proper grounding and that the site location includes a |

|

|

| grounding electrode system. |

|

|

15 | Verify that the site location has adequate lighting for the HP POD 20c installation. |

|

|

16 | Verify that a truck and equipment staging areas are identified. |

|

|

17 | Verify the location for the fuel tanks for generators, powerhouses, and other equipment, if |

|

|

| applicable. |

|

|

18 | Verify the locations for cranes |

|

|

19 | Verify site access and clearances for equipment, including the crane and forklifts. A clear |

|

|

| path to the site must be maintained with clearance for all gates, headers, utility lines, and so |

|

|

| on. |

|

|

20 | Verify that the locations for storage and trash disposal are identified. |

|

|

21 | Verify that the safety equipment is planned for and in place in accordance with the |

|

|

| customer’s site safety program. |

|

|

22 | Verify the site interfaces and locations which connect to the fire alarm, access control system, |

|

|

| and communication system to the HP POD 20c to ensure that the POD can be properly |

|

|

| connected to the site BMS. |

|

|

23 | Verify that proper disposal methods are used for existing or potentially contaminated and/or |

|

|

| hazardous materials. |

|

|

24 | Verify the availability of security systems or equipment, including site fences, which are |

|

|

| required after construction. |

|

|

25 | Verify the availability of temporary facilities associated with the relocation of existing |

|

|

| services and operations. |

|

|

26 | Verify that all work relating to soil testing, removal, and site remediation is complete. |

|

|

27 | Verify that a temporary or permanent load bank is available, if applicable. |

|

|

28 | Verify the location of the EPO system external to the powerhouses, if applicable. |

|

|

29 | Verify the location of the remote electronic monitoring system. |

|

|

30 | Verify that |

|

|

| containers are complete at least one week prior to arrival of |

|

|

General Water Supply |

|

| |

|

|

| |

Item | Description | Initial |

|

|

|

|

|

1 | Verify that the site drainage is complete, and the HP POD 20c is not in a drainage path or |

|

|

| flood prone area. HP recommends placing the HP POD 20c on a raised site pad to prevent |

|

|

| water from entering the HP POD 20c. |

|

|

2 | Verify that the humidification water quality meets or exceeds these standards, which are |

|

|

| essentially drinking water standards. |

|

|

3 | Verify the humidification water supply isolation valve is installed for each POD. |

|

|

Chilled Water Supply |

|

| |

|

|

| |

Item | Description | Initial |

|

|

|

|

|

1 | Verify the chilled water supply and return headers are accessible, are in the appropriate |

|

|

| location, and are 80 cm (3 in) in diameter. |

|

|

| Appendix B: Preparing for delivery 29 | ||

Page 29

Image 29