Page

Thank You

Table of Contents

Quad Layout

Upper Range

Delete Recording

Start Recording

Delete Image

Delete All Images

Navigation Menu Tab

Views Menu Tab

Page

How Sonar Works

Series Introduction

DualBeam Plus Sonar

Peak to Peak measures power output at the highest points

Purchase for 917c Combo models only

QuadraBeam Plus Sonar

Universal Sonar

How GPS and Cartography Work

GPS uses a constellation of 24 satellites that

Multi-Media Card MMC/SD Slot

Software Updates Accessory Bus

Installation Overview

Installing the GPS Receiver if included

Control Head Installation

Basic installation tasks that you must perform include

Washer Gimbal Knob Gimbal Bracket

Gimbal Mounting the Control Head

Mounting Screws

Cables Routed Directly Beneath Mounting Bracket

Cables Routed Behind Mounting Bracket

Connecting the Control Head Power Cable to the Boat

Transducer Installation

Locating the transducer mounting location

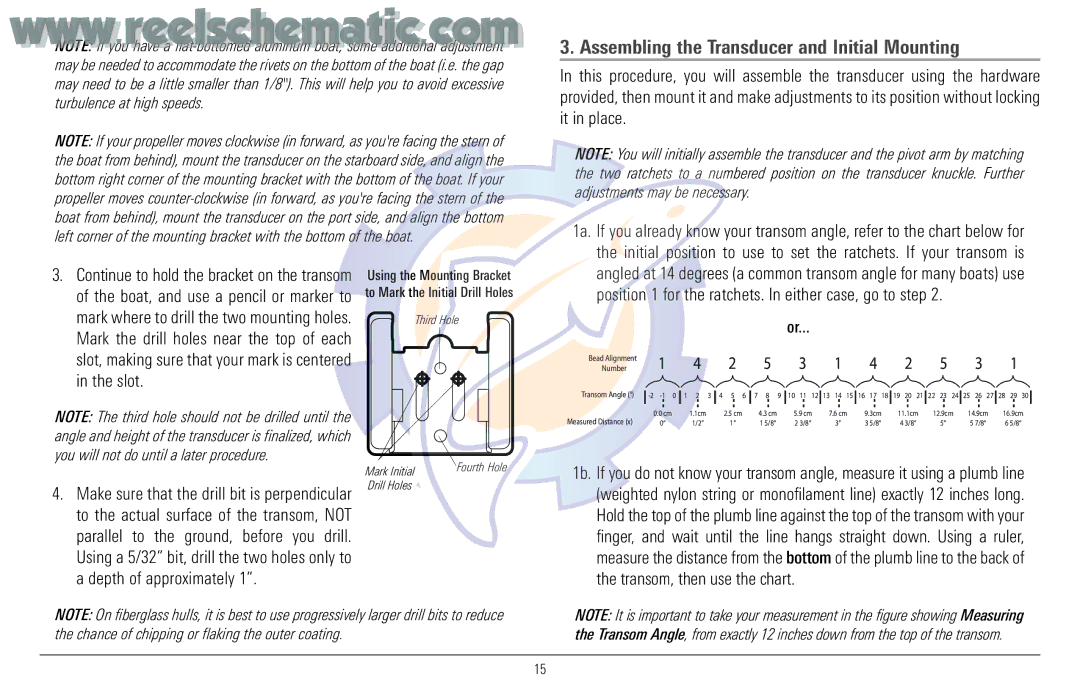

Transom Transducer Installation

Level

Preparing the Mounting Location

Assembling the Transducer and Initial Mounting

Knuckle

Mounting the Assembly to the Transom

Seam aligned with boat hull

Routing the Cable

Screw

Connecting the Cable

Test and Finish the Installation

Correctly,

Inside the Hull Transducer Installation

Determine the transducer mounting location

Trial installation

Permanently mount the transducer

Route the cable

Are included with the bracket

Trolling Motor Transducer Installation

If you have… Then use

GPS Receiver Installation

Trolling Motor Transducer Options

Abrasion

Stem Mounting with an Existing 1 14 Thread Stem

Follow these steps to stem mount the GPS receiver

No Access Under Mounting Location

Access Under Mounting Location

Finish Routing the Cable Check GPS Receiver Operation

To test the installation

Testing the System Installation

Powering Up the Control Head

Getting Started Using Your 900 Series

Triplog

What’s On the Sonar Display

Bottom Presentation

Understanding Sonar History

Real Time Sonar RTS Window

Key Functions

POWER/LIGHT Key

Menu Key

View Key

Exit Key

View Preset keys

WAY Cursor Control Key

Goto Key has multiple functions, depending on the situation

Info Key

Mark Key

Goto Key

Views and Readouts

Zoom +/- Keys

Views

Sonar View

Sonar View

Sonar Zoom View

Sonar Zoom View

Split Sonar View

Split Sonar View

Snapshot and Recording View

Page

Recording Slider Bar

Recording Playback

Only with QuadraBeam Plus transducer

Side Beam View

555

Bird’s Eye View

Bird’s Eye View

Chart/Bird’s Eye Combo View

Chart/Bird’s Eye Combo View

Chart/Chart Combo View

Chart/Chart Combo View

Chart View with Active Cursor

Chart View

Chart/Sonar Combo View

Chart/Sonar Combo View

Viewing Cartography

Chart Orientation

Navigation

Waypoints, Routes and Tracks

Waypoints, Routes and Tracks

Save, Edit, or Delete a Waypoint

Add a Waypoint Target or Trolling Grid

Navigate to a Waypoint or Position

Save, Edit or Delete a Route

Edit, Delete or Hide Saved Tracks

Save or Clear a Current Track

MOB Navigation

Man Overboard MOB Navigation

Com

Normal Simulator System Status

Start-Up Options Menu

Up Options menu

System Status

Exit Normal operation by powering your 900 Series off

Normal Operation

Simulator

Self Test

Accessory Test

GPS Diagnostic View

Active Side

Sonar X-Press Menu

Sensitivity

Split Position

Advanced Sonar, Split Sonar Active Sonar Side Views only

Upper Range

Lower Range

With QuadraBeam Plus Transducer, Side Beam View only

Chart Speed

Quad Layout

Sonar Colors

Cancel Navigation

Bottom Lock

Bottom Range

Navigation X-Press Menu

Only with an active cursor on a waypoint

Chart or Combo view only

Waypoint Name

Cursor to Waypoint

Skip Next Waypoint

Save Current Track

Clear Current Track

Save Current Route

Remove Grid

Cancel MOB Navigation

To Cancel MOB Navigation

Remove Target

Most recently-created waypoint

Optional-purchase MMC/SD Card, Snapshot Recording View only

Start Recording

Stop Recording

Snapshot and Recording View only

To delete an image

Delete Image

Delete All Images

Delete All Recordings

Delete Recording

To specify playback speed

Pings Per Second

Playback Speed

Sonar Menu Tab

Stop Playback

Transducer will be displayed on the screen

Beam Select

Fish ID+

Fish ID Sensitivity

Zoom Width

Bottom View

Optional-purchase for

To change the 455 kHz Sensitivity setting

KHz Sensitivity

Advanced

Depth Lines

Surface Clutter

Max Depth

Noise Filter

Color Bar

Water Type

Transducer Select

Navigation Menu Tab

Temperature Graph

Sonar View only, with Temperature input

Saved Tracks

Current Track

Waypoints Submenu contains the following menu choices

Waypoints

Routes

North Reference

Track Min Distance

Trolling Grid Rotation

Trackpoint Interval

Export All Nav Data

Track Color Range

Map Datum

Course Projection Line

Delete All Nav Data

Continuous Navigation Mode

Chart Menu Tab

Continuous Navigation Mode allows you to

Map Borders

Chart Detail Level

Shaded Depth

Lat/Lon Grid

Spot Soundings

Navaids on Birds Eye View

Set Map Offset

Set Simulation Position

Clear Map Offset

Alarms Menu Tab

Low Battery Alarm

Depth Alarm

Fish ID Alarm

Temp Alarm

Aux Temp Alarm

Off Course Alarm

Arrival Alarm

Alarm Tone

Drift Alarm

International only

Setup Menu Tab

Units Depth

Units Temp

Language

User Mode

Units Distance

Units Speed

Select Readouts

Triplog Reset

Restore Defaults

Off Triplog Position Voltage Aux. Temperature

Page

Temp Offset

Depth Offset

Aux Temp Offset

Position Format

Speed Calibration

Local Time Zone

Daylight Saving Time

Advanced, International only

Time Format

Date Format

Nmea Output

Digits Format

Views Menu Tab

Following views are available

Using Screen Snapshot

Accessories Menu Tab

To turn Screen Snapshot on or off

Series Doesn’t Power Up

Troubleshooting

Control head loses power at high speeds

Display Problems

Finding the Cause of Noise

Humminbird Service Policy

Year Limited Warranty

Returning Your Unit for Service

Series include

Series Accessories

Page

Specifications

Glossary

123

Com Atic

Receiver See Transmitter

Com Atic

Sonar Terms

Glossary GPS & Navigation Terms

129

Glossary GPS & Navigation Terms

Glossary GPS & Navigation Terms

Glossary GPS & Navigation Terms

Contact Humminbird