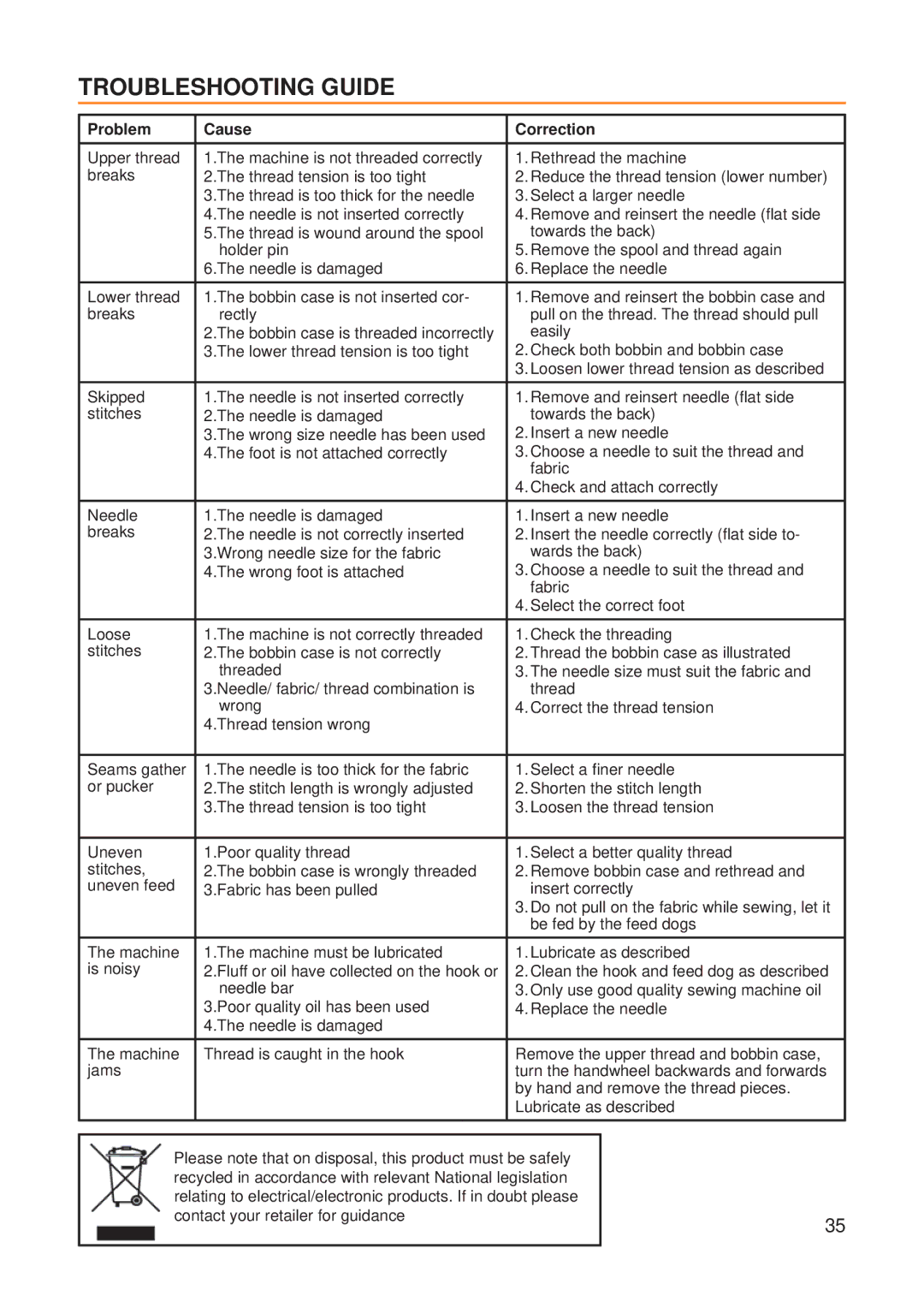

TROUBLESHOOTING GUIDE

Problem | Cause | Correction |

|

|

|

Upper thread | 1.The machine is not threaded correctly | 1. Rethread the machine |

breaks | 2.The thread tension is too tight | 2. Reduce the thread tension (lower number) |

| 3.The thread is too thick for the needle | 3. Select a larger needle |

| 4.The needle is not inserted correctly | 4. Remove and reinsert the needle (flat side |

| 5.The thread is wound around the spool | towards the back) |

| holder pin | 5. Remove the spool and thread again |

| 6.The needle is damaged | 6. Replace the needle |

|

|

|

Lower thread | 1.The bobbin case is not inserted cor- | 1. Remove and reinsert the bobbin case and |

breaks | rectly | pull on the thread. The thread should pull |

| 2.The bobbin case is threaded incorrectly | easily |

| 3.The lower thread tension is too tight | 2. Check both bobbin and bobbin case |

|

| 3. Loosen lower thread tension as described |

|

|

|

Skipped | 1.The needle is not inserted correctly | 1. Remove and reinsert needle (flat side |

stitches | 2.The needle is damaged | towards the back) |

| 3.The wrong size needle has been used | 2. Insert a new needle |

| 4.The foot is not attached correctly | 3. Choose a needle to suit the thread and |

|

| fabric |

|

| 4. Check and attach correctly |

|

|

|

Needle | 1.The needle is damaged | 1. Insert a new needle |

breaks | 2.The needle is not correctly inserted | 2. Insert the needle correctly (flat side to- |

| 3.Wrong needle size for the fabric | wards the back) |

| 4.The wrong foot is attached | 3. Choose a needle to suit the thread and |

|

| fabric |

|

| 4. Select the correct foot |

|

|

|

Loose | 1.The machine is not correctly threaded | 1. Check the threading |

stitches | 2.The bobbin case is not correctly | 2. Thread the bobbin case as illustrated |

| threaded | 3. The needle size must suit the fabric and |

| 3.Needle/ fabric/ thread combination is | thread |

| wrong | 4. Correct the thread tension |

| 4.Thread tension wrong |

|

|

|

|

Seams gather | 1.The needle is too thick for the fabric | 1. Select a finer needle |

or pucker | 2.The stitch length is wrongly adjusted | 2. Shorten the stitch length |

| 3.The thread tension is too tight | 3. Loosen the thread tension |

|

|

|

Uneven | 1.Poor quality thread | 1. Select a better quality thread |

stitches, | 2.The bobbin case is wrongly threaded | 2. Remove bobbin case and rethread and |

uneven feed | 3.Fabric has been pulled | insert correctly |

|

| 3. Do not pull on the fabric while sewing, let it |

|

| be fed by the feed dogs |

|

|

|

The machine | 1.The machine must be lubricated | 1. Lubricate as described |

is noisy | 2.Fluff or oil have collected on the hook or | 2. Clean the hook and feed dog as described |

| needle bar | 3. Only use good quality sewing machine oil |

| 3.Poor quality oil has been used | 4. Replace the needle |

| 4.The needle is damaged |

|

|

|

|

The machine | Thread is caught in the hook | Remove the upper thread and bobbin case, |

jams |

| turn the handwheel backwards and forwards |

|

| by hand and remove the thread pieces. |

|

| Lubricate as described |

|

|

|

Please note that on disposal, this product must be safely recycled in accordance with relevant National legislation relating to electrical/electronic products. If in doubt please contact your retailer for guidance

35