Connecting Sander to a Dust Collector

Dust collection is necessary for all drum sanders. The Performax

JET offers a variety of Dust Collectors and Air Filtration Units that will work nicely with your new sander. Contact your local distributor for more information.

Depth Gauge

The depth gauge indicates the distance from the bottom of the drum to the top of the conveyor.

1.Lower the drum, with sandpaper installed, until it touches the conveyor.

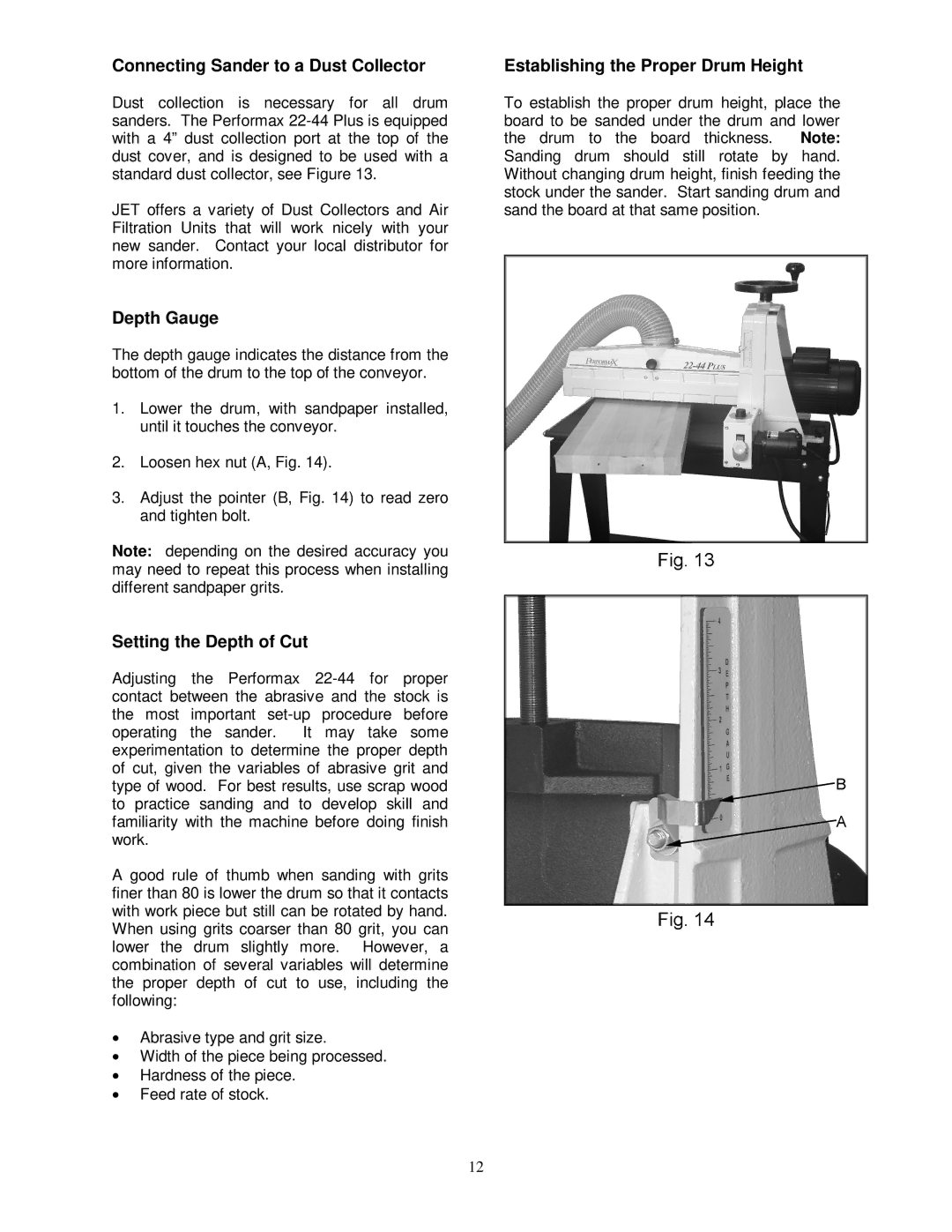

2.Loosen hex nut (A, Fig. 14).

3.Adjust the pointer (B, Fig. 14) to read zero and tighten bolt.

Note: depending on the desired accuracy you may need to repeat this process when installing different sandpaper grits.

Setting the Depth of Cut

Adjusting the Performax

A good rule of thumb when sanding with grits finer than 80 is lower the drum so that it contacts with work piece but still can be rotated by hand. When using grits coarser than 80 grit, you can lower the drum slightly more. However, a combination of several variables will determine the proper depth of cut to use, including the following:

•Abrasive type and grit size.

•Width of the piece being processed.

•Hardness of the piece.

•Feed rate of stock.

Establishing the Proper Drum Height

To establish the proper drum height, place the board to be sanded under the drum and lower the drum to the board thickness. Note: Sanding drum should still rotate by hand. Without changing drum height, finish feeding the stock under the sander. Start sanding drum and sand the board at that same position.

12