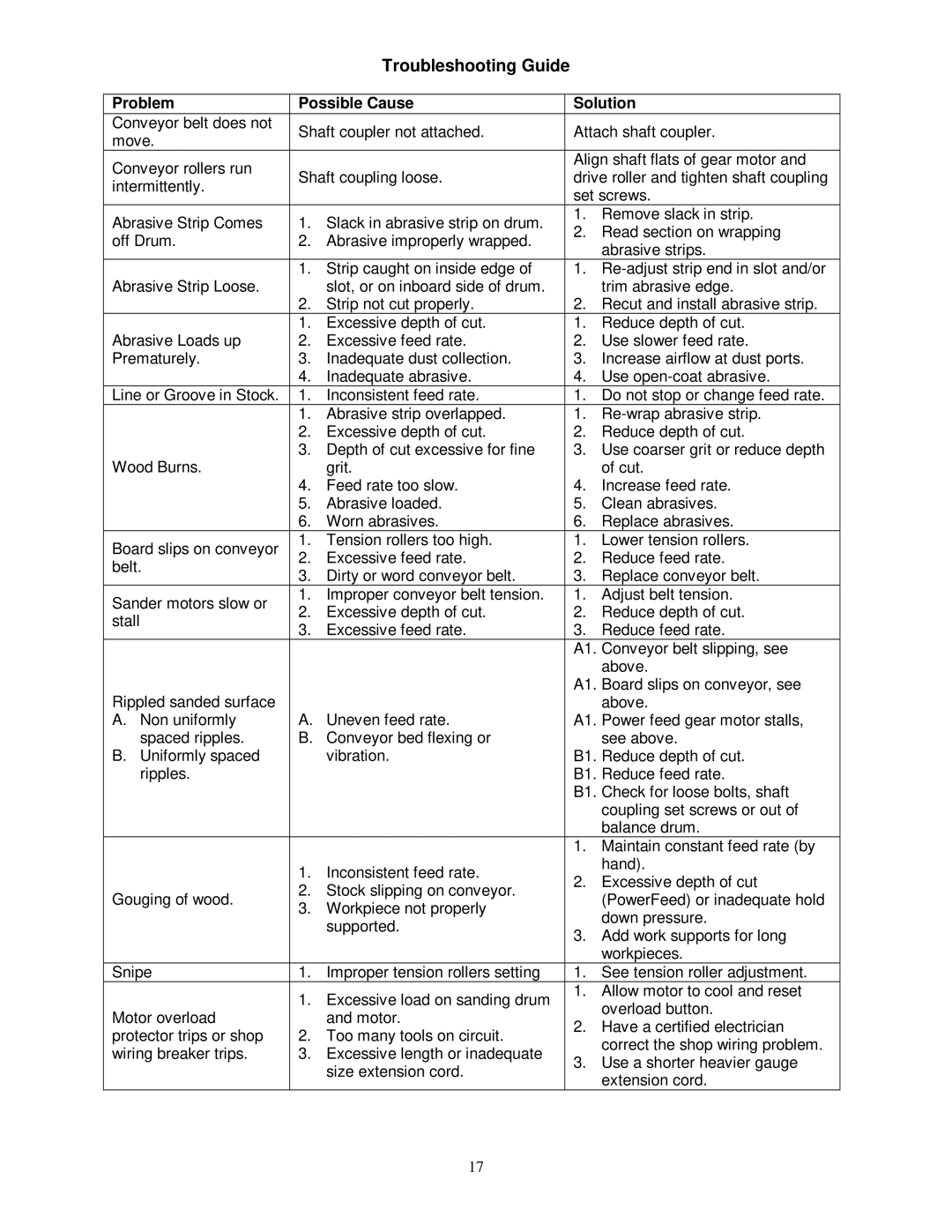

Troubleshooting Guide

Problem | Possible Cause | Solution | ||||

Conveyor belt does not | Shaft coupler not attached. | Attach shaft coupler. | ||||

move. | ||||||

|

|

|

| |||

Conveyor rollers run |

|

| Align shaft flats of gear motor and | |||

Shaft coupling loose. | drive roller and tighten shaft coupling | |||||

intermittently. | ||||||

|

| set screws. | ||||

|

|

|

| |||

Abrasive Strip Comes | 1. | Slack in abrasive strip on drum. | 1. | Remove slack in strip. | ||

2. | Read section on wrapping | |||||

off Drum. | 2. | Abrasive improperly wrapped. | ||||

| abrasive strips. | |||||

|

|

|

|

| ||

|

| 1. | Strip caught on inside edge of | 1. | ||

Abrasive Strip Loose. |

| slot, or on inboard side of drum. |

| trim abrasive edge. | ||

|

| 2. | Strip not cut properly. | 2. | Recut and install abrasive strip. | |

Abrasive Loads up | 1. | Excessive depth of cut. | 1. | Reduce depth of cut. | ||

2. | Excessive feed rate. | 2. | Use slower feed rate. | |||

Prematurely. | 3. | Inadequate dust collection. | 3. | Increase airflow at dust ports. | ||

|

| 4. | Inadequate abrasive. | 4. | Use | |

Line or Groove in Stock. | 1. | Inconsistent feed rate. | 1. | Do not stop or change feed rate. | ||

|

| 1. | Abrasive strip overlapped. | 1. | ||

|

| 2. | Excessive depth of cut. | 2. | Reduce depth of cut. | |

Wood Burns. | 3. | Depth of cut excessive for fine | 3. | Use coarser grit or reduce depth | ||

| grit. |

| of cut. | |||

|

| 4. | Feed rate too slow. | 4. | Increase feed rate. | |

|

| 5. | Abrasive loaded. | 5. | Clean abrasives. | |

|

| 6. | Worn abrasives. | 6. | Replace abrasives. | |

Board slips on conveyor | 1. | Tension rollers too high. | 1. | Lower tension rollers. | ||

2. | Excessive feed rate. | 2. | Reduce feed rate. | |||

belt. | ||||||

3. | Dirty or word conveyor belt. | 3. | Replace conveyor belt. | |||

|

| |||||

Sander motors slow or | 1. | Improper conveyor belt tension. | 1. | Adjust belt tension. | ||

2. | Excessive depth of cut. | 2. | Reduce depth of cut. | |||

stall |

| |||||

| 3. | Excessive feed rate. | 3. | Reduce feed rate. | ||

|

| |||||

|

|

|

| A1. | Conveyor belt slipping, see | |

|

|

|

|

| above. | |

Rippled sanded surface |

|

| A1. | Board slips on conveyor, see | ||

|

|

| above. | |||

A. | Non uniformly | A. | Uneven feed rate. | A1. | Power feed gear motor stalls, | |

| spaced ripples. | B. | Conveyor bed flexing or |

| see above. | |

B. | Uniformly spaced |

| vibration. | B1. | Reduce depth of cut. | |

| ripples. |

|

| B1. | Reduce feed rate. | |

|

|

|

| B1. | Check for loose bolts, shaft | |

|

|

|

|

| coupling set screws or out of | |

|

|

|

|

| balance drum. | |

|

|

|

| 1. | Maintain constant feed rate (by | |

|

| 1. | Inconsistent feed rate. |

| hand). | |

|

| 2. | Excessive depth of cut | |||

Gouging of wood. | 2. | Stock slipping on conveyor. | ||||

| (PowerFeed) or inadequate hold | |||||

3. | Workpiece not properly |

| ||||

|

|

| down pressure. | |||

|

|

| supported. |

| ||

|

|

| 3. | Add work supports for long | ||

|

|

|

| |||

|

|

|

|

| workpieces. | |

Snipe | 1. | Improper tension rollers setting | 1. | See tension roller adjustment. | ||

|

| 1. | Excessive load on sanding drum | 1. | Allow motor to cool and reset | |

Motor overload |

| overload button. | ||||

| and motor. |

| ||||

| 2. | Have a certified electrician | ||||

protector trips or shop | 2. | Too many tools on circuit. | ||||

| correct the shop wiring problem. | |||||

wiring breaker trips. | 3. | Excessive length or inadequate |

| |||

3. | Use a shorter heavier gauge | |||||

|

|

| size extension cord. | |||

|

|

|

| extension cord. | ||

|

|

|

|

| ||

17