Drain oil completely and refill after the first three months of operation. Then, change oil in the apron annually. Pull knob (C, Figure

5)on the

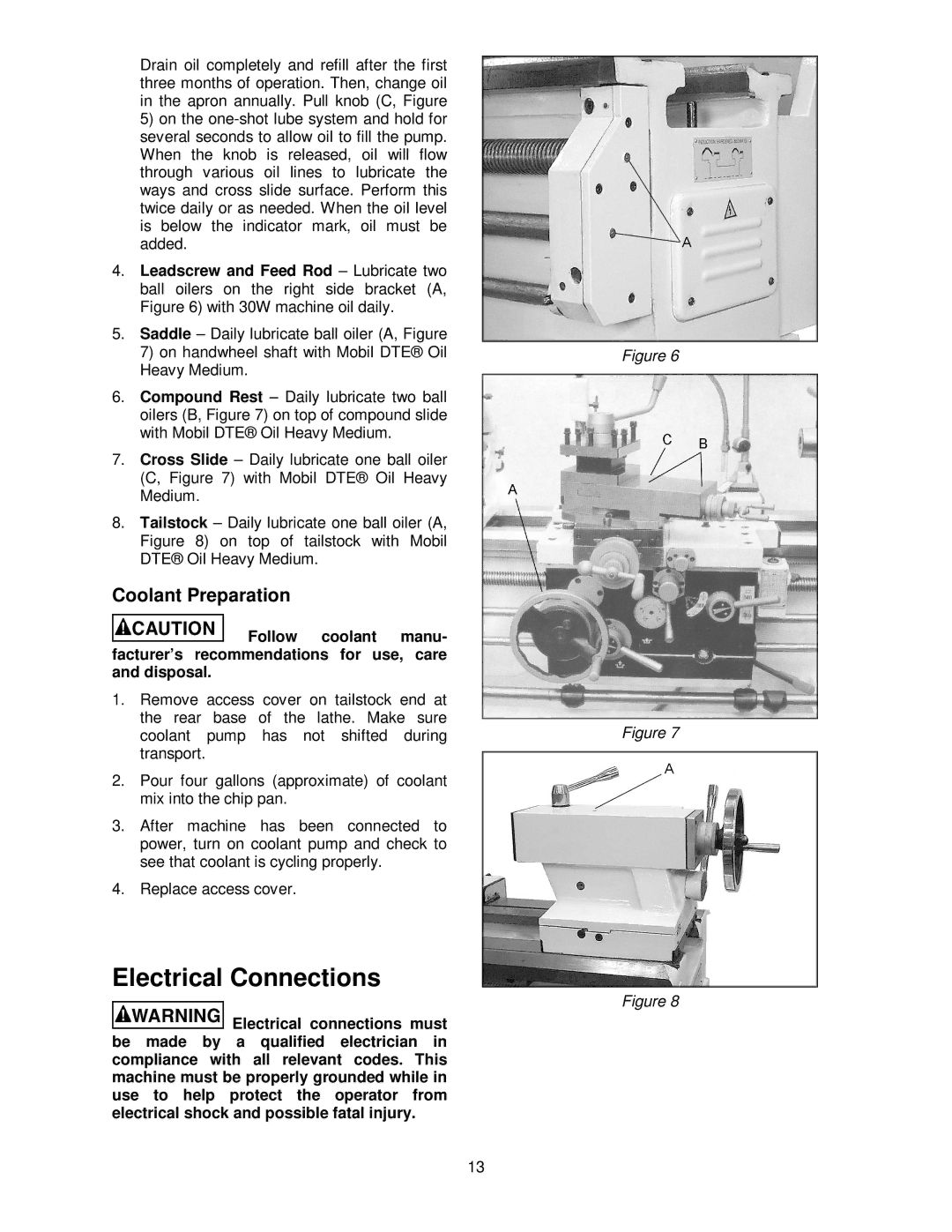

4.Leadscrew and Feed Rod – Lubricate two ball oilers on the right side bracket (A, Figure 6) with 30W machine oil daily.

5.Saddle – Daily lubricate ball oiler (A, Figure

7)on handwheel shaft with Mobil DTE® Oil Heavy Medium.

6.Compound Rest – Daily lubricate two ball oilers (B, Figure 7) on top of compound slide with Mobil DTE® Oil Heavy Medium.

7.Cross Slide – Daily lubricate one ball oiler (C, Figure 7) with Mobil DTE® Oil Heavy Medium.

8.Tailstock – Daily lubricate one ball oiler (A, Figure 8) on top of tailstock with Mobil DTE® Oil Heavy Medium.

Coolant Preparation

![]() Follow coolant manu- facturer’s recommendations for use, care and disposal.

Follow coolant manu- facturer’s recommendations for use, care and disposal.

1.Remove access cover on tailstock end at the rear base of the lathe. Make sure coolant pump has not shifted during transport.

2.Pour four gallons (approximate) of coolant mix into the chip pan.

3.After machine has been connected to power, turn on coolant pump and check to see that coolant is cycling properly.

4.Replace access cover.

Electrical Connections

![]() Electrical connections must be made by a qualified electrician in compliance with all relevant codes. This machine must be properly grounded while in use to help protect the operator from electrical shock and possible fatal injury.

Electrical connections must be made by a qualified electrician in compliance with all relevant codes. This machine must be properly grounded while in use to help protect the operator from electrical shock and possible fatal injury.

Figure 6

Figure 7

Figure 8

13