The main motor is rated at

Power is connected properly when rotating the

Conversion to 460 Volt Operation

![]() Disconnect machine from power source. Failure to do so may cause serious injury.

Disconnect machine from power source. Failure to do so may cause serious injury.

Main Motor: Change the wires according to the diagram on the outside of the motor junction box.

Transformer: Open electrical panel on rear of machine on the headstock side. Switch wire from 230V terminal to 460V terminal as outlined on the transformer.

Coolant Pump: Open access panel on the base at the tailstock end. Change wires in coolant pump junction box according to diagram on the outside of the junction box cover.

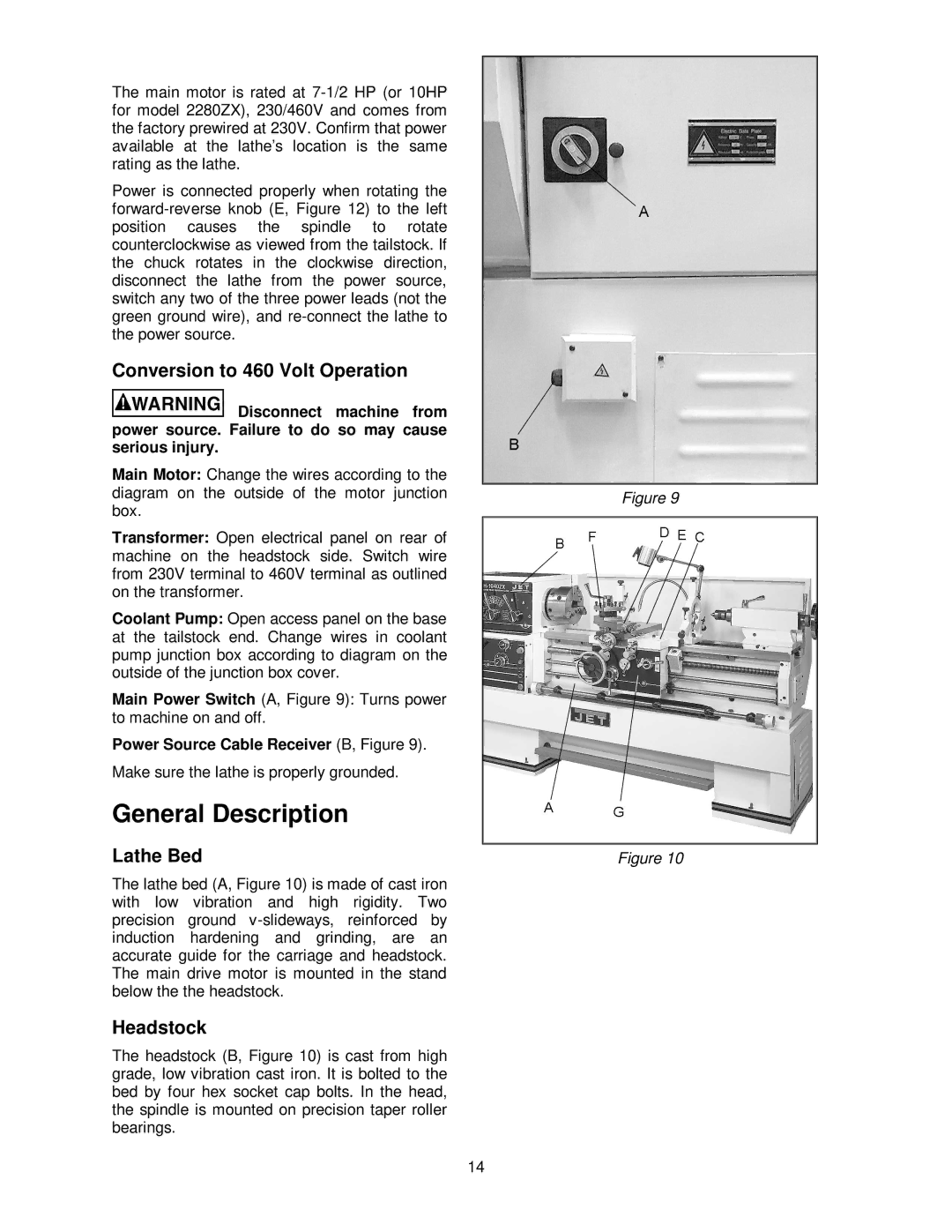

Main Power Switch (A, Figure 9): Turns power to machine on and off.

Power Source Cable Receiver (B, Figure 9).

Make sure the lathe is properly grounded.

General Description

Lathe Bed

The lathe bed (A, Figure 10) is made of cast iron with low vibration and high rigidity. Two precision ground

Headstock

The headstock (B, Figure 10) is cast from high grade, low vibration cast iron. It is bolted to the bed by four hex socket cap bolts. In the head, the spindle is mounted on precision taper roller bearings.

14

Figure 9

Figure 10