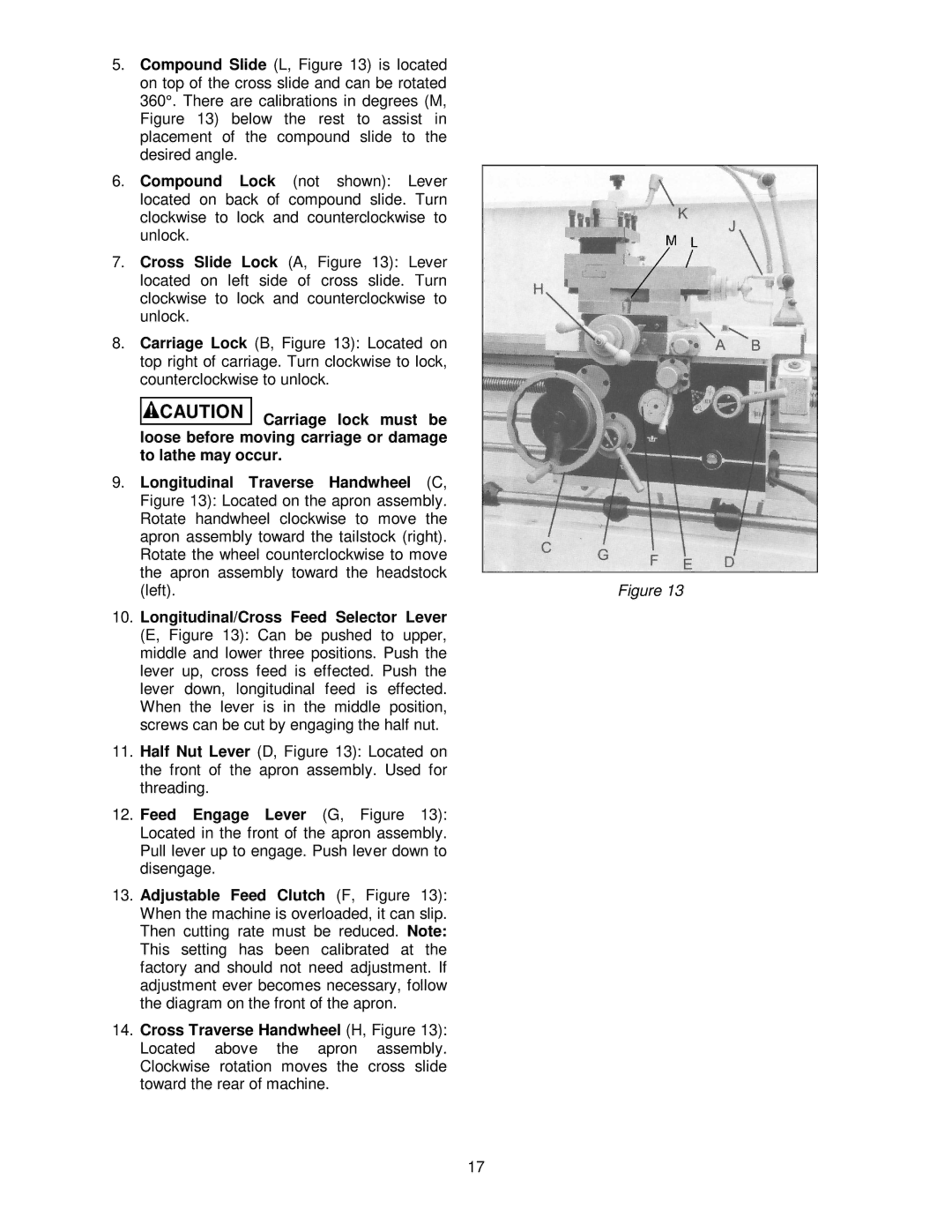

5.Compound Slide (L, Figure 13) is located on top of the cross slide and can be rotated 360°. There are calibrations in degrees (M, Figure 13) below the rest to assist in placement of the compound slide to the desired angle.

6.Compound Lock (not shown): Lever located on back of compound slide. Turn clockwise to lock and counterclockwise to unlock.

7.Cross Slide Lock (A, Figure 13): Lever located on left side of cross slide. Turn clockwise to lock and counterclockwise to unlock.

8.Carriage Lock (B, Figure 13): Located on top right of carriage. Turn clockwise to lock, counterclockwise to unlock.

![]() Carriage lock must be loose before moving carriage or damage to lathe may occur.

Carriage lock must be loose before moving carriage or damage to lathe may occur.

9.Longitudinal Traverse Handwheel (C, Figure 13): Located on the apron assembly. Rotate handwheel clockwise to move the apron assembly toward the tailstock (right). Rotate the wheel counterclockwise to move the apron assembly toward the headstock

(left). | Figure 13 |

10.Longitudinal/Cross Feed Selector Lever (E, Figure 13): Can be pushed to upper, middle and lower three positions. Push the lever up, cross feed is effected. Push the lever down, longitudinal feed is effected. When the lever is in the middle position, screws can be cut by engaging the half nut.

11.Half Nut Lever (D, Figure 13): Located on the front of the apron assembly. Used for threading.

12.Feed Engage Lever (G, Figure 13): Located in the front of the apron assembly. Pull lever up to engage. Push lever down to disengage.

13.Adjustable Feed Clutch (F, Figure 13): When the machine is overloaded, it can slip. Then cutting rate must be reduced. Note: This setting has been calibrated at the factory and should not need adjustment. If adjustment ever becomes necessary, follow the diagram on the front of the apron.

14.Cross Traverse Handwheel (H, Figure 13): Located above the apron assembly. Clockwise rotation moves the cross slide toward the rear of machine.

17