Stand Assembly (optional accessory)

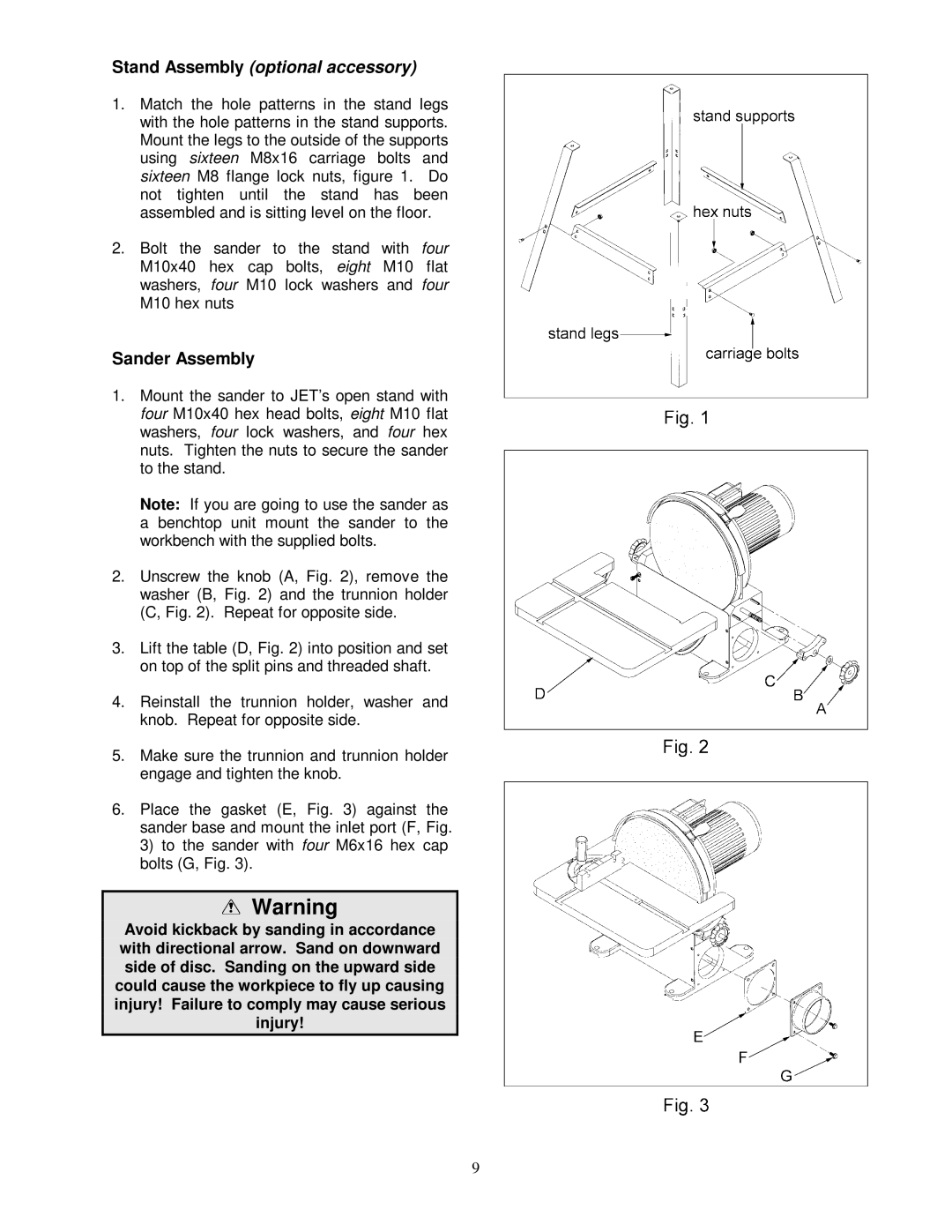

1.Match the hole patterns in the stand legs with the hole patterns in the stand supports. Mount the legs to the outside of the supports using sixteen M8x16 carriage bolts and sixteen M8 flange lock nuts, figure 1. Do not tighten until the stand has been assembled and is sitting level on the floor.

2.Bolt the sander to the stand with four M10x40 hex cap bolts, eight M10 flat washers, four M10 lock washers and four M10 hex nuts

Sander Assembly

1.Mount the sander to JET’s open stand with four M10x40 hex head bolts, eight M10 flat washers, four lock washers, and four hex nuts. Tighten the nuts to secure the sander to the stand.

Note: If you are going to use the sander as a benchtop unit mount the sander to the workbench with the supplied bolts.

2.Unscrew the knob (A, Fig. 2), remove the washer (B, Fig. 2) and the trunnion holder (C, Fig. 2). Repeat for opposite side.

3.Lift the table (D, Fig. 2) into position and set on top of the split pins and threaded shaft.

4.Reinstall the trunnion holder, washer and knob. Repeat for opposite side.

5.Make sure the trunnion and trunnion holder engage and tighten the knob.

6.Place the gasket (E, Fig. 3) against the sander base and mount the inlet port (F, Fig.

3)to the sander with four M6x16 hex cap bolts (G, Fig. 3).

Warning

Avoid kickback by sanding in accordance with directional arrow. Sand on downward side of disc. Sanding on the upward side could cause the workpiece to fly up causing injury! Failure to comply may cause serious injury!

9