Sharpening Chisel and Auger

The chisel and auger should be kept sharp for best performance. If cutting operations require excessive force, the chisel and/or auger are probably dull and should be sharpened. Blunt edges will give inaccurate mortises and can lead to overheating and breakage of chisel or auger. If chisel and auger are badly worn and become difficult to sharpen, they should be replaced.

Chisel

Sharpen the chisel with a mortise chisel cutter with the correct size pilot. (Pilot size will differ depending on the size of your chisel.) Two or three turns of the cutter in a carpenter’s brace chuck should be enough to sharpen the chisel, as shown in Figure 22.

Use a small, triangular, smooth file to relieve the inner corners of the chisel (Figure 23). Remove any burrs from the outside of the chisel with a fine oilstone.

Auger

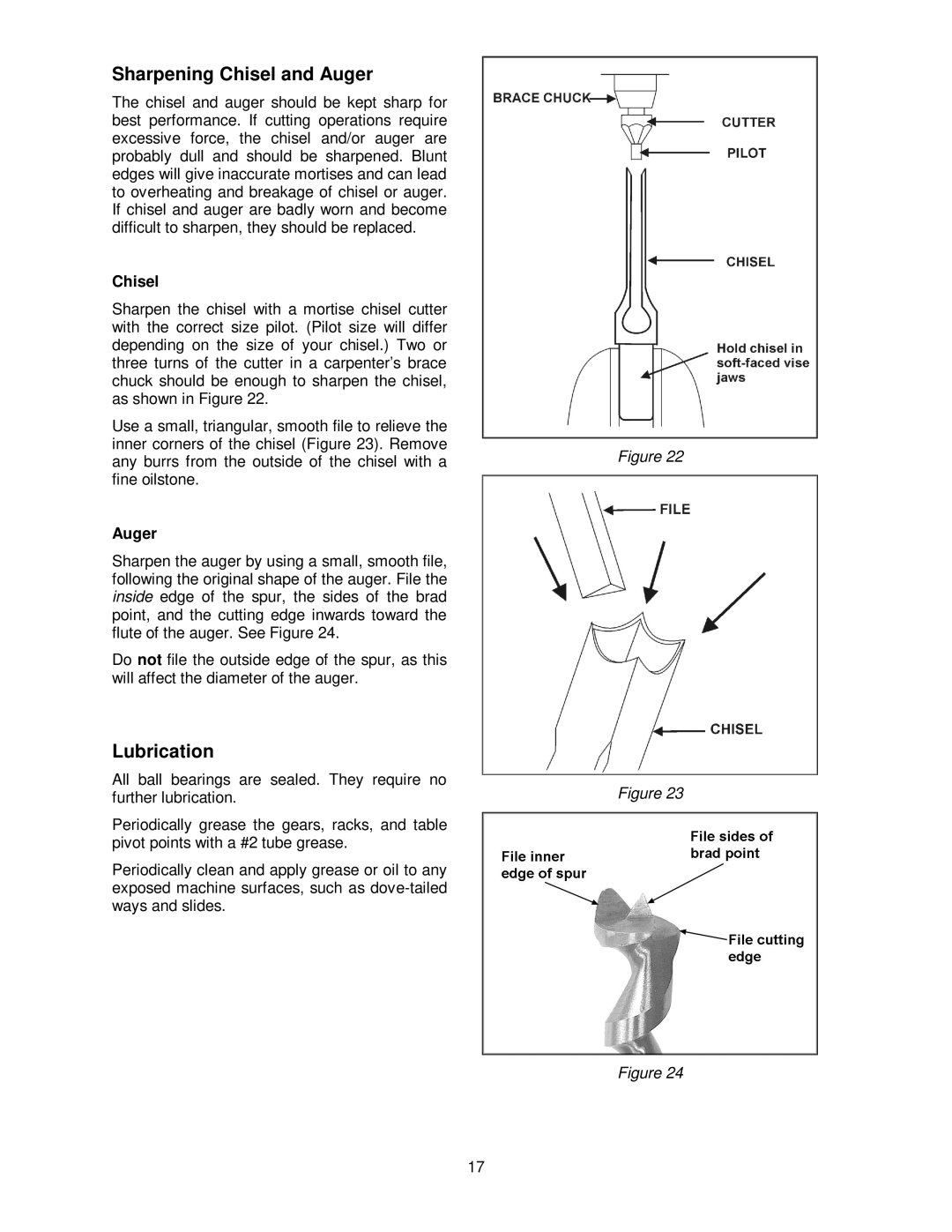

Sharpen the auger by using a small, smooth file, following the original shape of the auger. File the inside edge of the spur, the sides of the brad point, and the cutting edge inwards toward the flute of the auger. See Figure 24.

Do not file the outside edge of the spur, as this will affect the diameter of the auger.

Lubrication

All ball bearings are sealed. They require no further lubrication.

Periodically grease the gears, racks, and table pivot points with a #2 tube grease.

Periodically clean and apply grease or oil to any exposed machine surfaces, such as

Figure 22

Figure 23

Figure 24

17