ACPU024 THRU 060 specifications

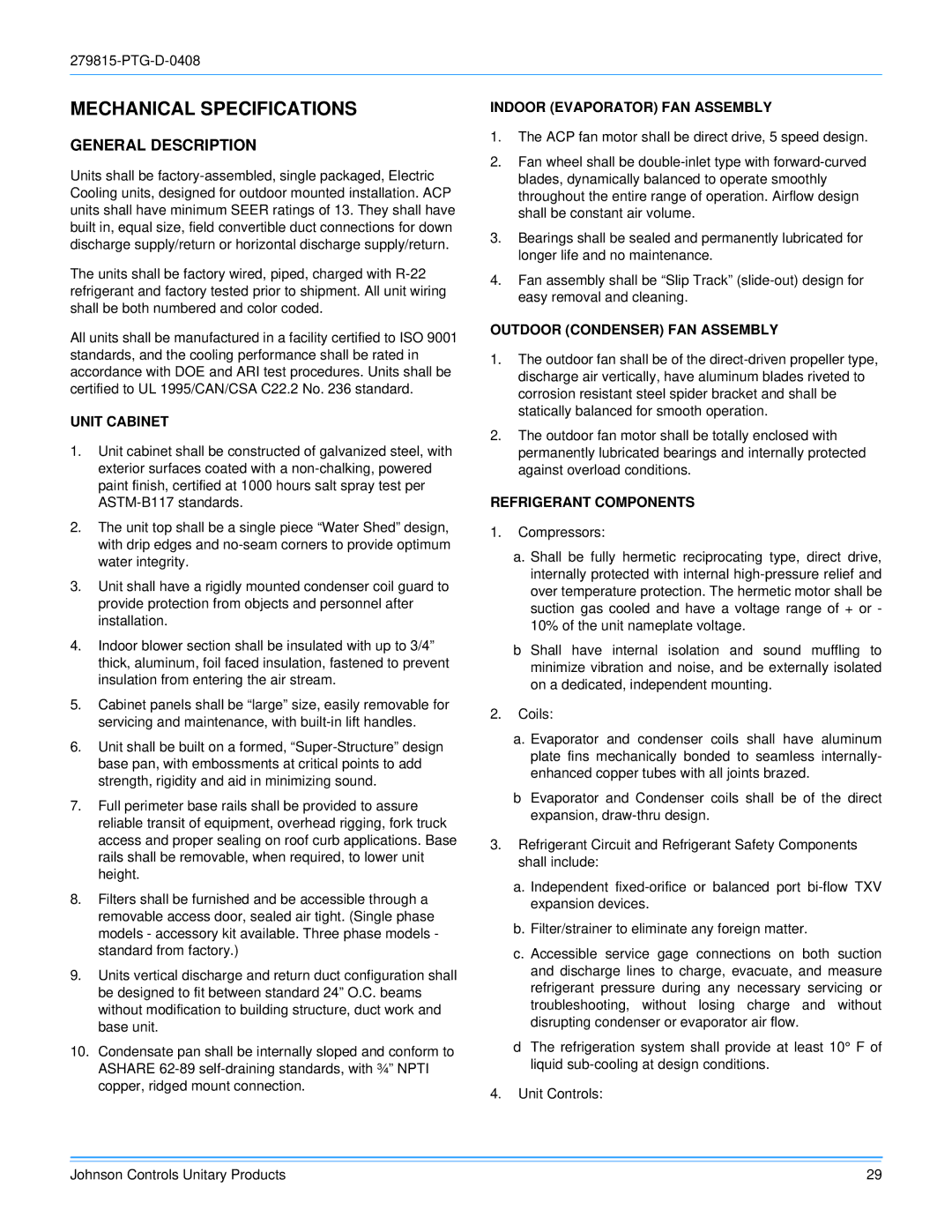

Johnson Controls ACPU024 THRU 060 is a series of advanced air conditioning units designed to deliver efficiency, reliability, and optimal performance in various commercial and industrial settings. These air conditioning units are part of Johnson Controls' commitment to providing innovative solutions that meet the growing demands for energy efficiency and sustainable practices within the HVAC industry.One of the standout features of the ACPU024 THRU 060 series is its exceptional energy efficiency. These units are equipped with high-efficiency scroll compressors and advanced coil designs that enhance heat exchange performance. This results in lower operating costs and reduced energy consumption, making the units a wise choice for businesses looking to minimize their environmental footprint while optimizing their operational expenses.

The ACPU models come with a wide range of capacities, from 024 to 060 tons, allowing for versatile application in settings ranging from offices to large commercial facilities. Additionally, they feature multiple airflow configurations, enabling customization to suit specific installation needs and enhance indoor air quality. This flexibility provides building managers and HVAC professionals with an ability to tailor the system to meet specific load requirements.

Technologically, the ACPU series incorporates smart controls and monitoring systems that give users real-time data on performance and energy usage. The user-friendly interface simplifies adjustments, scheduling, and diagnostics, making maintenance more straightforward and ensuring peak operation efficiency. The advanced controls are designed to integrate seamlessly with building management systems, promoting even higher levels of operational efficiency through automation.

Another important characteristic of the ACPU024 THRU 060 series is its design, tailored for durability and ease of installation. The units are constructed with weather-resistant materials, ensuring longevity even in challenging environments. Moreover, the modular design facilitates easy access to components for maintenance and repairs, reducing downtime and enhancing productivity.

In summary, Johnson Controls ACPU024 THRU 060 series is a leading choice for those seeking robust, energy-efficient air conditioning solutions. With its advanced technology, flexibility in application, and focus on sustainability, it stands out as a reliable choice for enhancing indoor comfort while also meeting regulatory energy standards.