Mighty Therm Volume Water Heater | Page 21 |

|

|

|

|

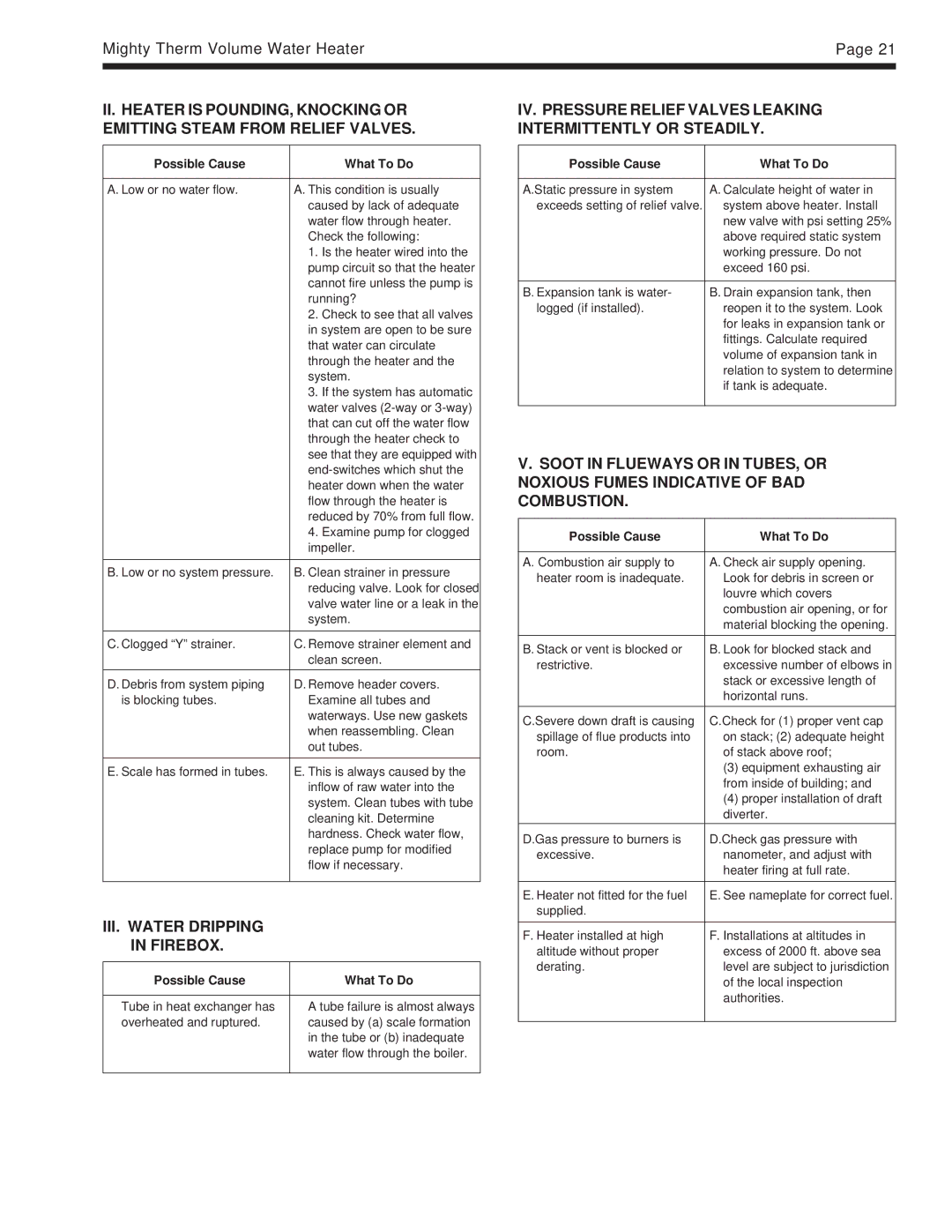

II.HEATER IS POUNDING, KNOCKING OR EMITTING STEAM FROM RELIEF VALVES.

Possible Cause | What To Do |

|

|

A. Low or no water flow. | A. This condition is usually |

| caused by lack of adequate |

| water flow through heater. |

| Check the following: |

| 1. Is the heater wired into the |

| pump circuit so that the heater |

| cannot fire unless the pump is |

| running? |

| 2. Check to see that all valves |

| in system are open to be sure |

| that water can circulate |

| through the heater and the |

| system. |

| 3. If the system has automatic |

| water valves |

| that can cut off the water flow |

| through the heater check to |

| see that they are equipped with |

| |

| heater down when the water |

| flow through the heater is |

| reduced by 70% from full flow. |

| 4. Examine pump for clogged |

| impeller. |

|

|

B. Low or no system pressure. | B. Clean strainer in pressure |

| reducing valve. Look for closed |

| valve water line or a leak in the |

| system. |

|

|

C. Clogged “Y” strainer. | C. Remove strainer element and |

| clean screen. |

|

|

D. Debris from system piping | D. Remove header covers. |

is blocking tubes. | Examine all tubes and |

| waterways. Use new gaskets |

| when reassembling. Clean |

| out tubes. |

|

|

E. Scale has formed in tubes. | E. This is always caused by the |

| inflow of raw water into the |

| system. Clean tubes with tube |

| cleaning kit. Determine |

| hardness. Check water flow, |

| replace pump for modified |

| flow if necessary. |

|

|

III. WATER DRIPPING

IN FIREBOX.

Possible Cause | What To Do |

|

|

Tube in heat exchanger has | A tube failure is almost always |

overheated and ruptured. | caused by (a) scale formation |

| in the tube or (b) inadequate |

| water flow through the boiler. |

|

|

IV. PRESSURE RELIEF VALVES LEAKING INTERMITTENTLY OR STEADILY.

Possible Cause | What To Do |

|

|

A.Static pressure in system | A. Calculate height of water in |

exceeds setting of relief valve. | system above heater. Install |

| new valve with psi setting 25% |

| above required static system |

| working pressure. Do not |

| exceed 160 psi. |

|

|

B. Expansion tank is water- | B. Drain expansion tank, then |

logged (if installed). | reopen it to the system. Look |

| for leaks in expansion tank or |

| fittings. Calculate required |

| volume of expansion tank in |

| relation to system to determine |

| if tank is adequate. |

|

|

V.SOOT IN FLUEWAYS OR IN TUBES, OR NOXIOUS FUMES INDICATIVE OF BAD COMBUSTION.

Possible Cause | What To Do |

|

|

A. Combustion air supply to | A. Check air supply opening. |

heater room is inadequate. | Look for debris in screen or |

| louvre which covers |

| combustion air opening, or for |

| material blocking the opening. |

|

|

B. Stack or vent is blocked or | B. Look for blocked stack and |

restrictive. | excessive number of elbows in |

| stack or excessive length of |

| horizontal runs. |

|

|

C.Severe down draft is causing | C.Check for (1) proper vent cap |

spillage of flue products into | on stack; (2) adequate height |

room. | of stack above roof; |

| (3) equipment exhausting air |

| from inside of building; and |

| (4) proper installation of draft |

| diverter. |

|

|

D.Gas pressure to burners is | D.Check gas pressure with |

excessive. | nanometer, and adjust with |

| heater firing at full rate. |

|

|

E. Heater not fitted for the fuel | E. See nameplate for correct fuel. |

supplied. |

|

|

|

F. Heater installed at high | F. Installations at altitudes in |

altitude without proper | excess of 2000 ft. above sea |

derating. | level are subject to jurisdiction |

| of the local inspection |

| authorities. |

|

|