LSM40ST-N-PV specifications

The Lennox Hearth LSM40ST-N-PV is a premium gas fireplace that combines elegance with advanced technology to create an unparalleled heating experience. Designed for both aesthetic appeal and functional efficiency, this model is perfect for homeowners seeking to enhance their living spaces while enjoying the warmth of a traditional fireplace.One of the standout features of the LSM40ST-N-PV is its sleek and contemporary design. The fireplace boasts a clean face, which allows for a larger viewing area, ensuring that the mesmerizing flames become the focal point of any room. Its glass front adds a modern touch, making it suitable for various interior styles, from classic to contemporary.

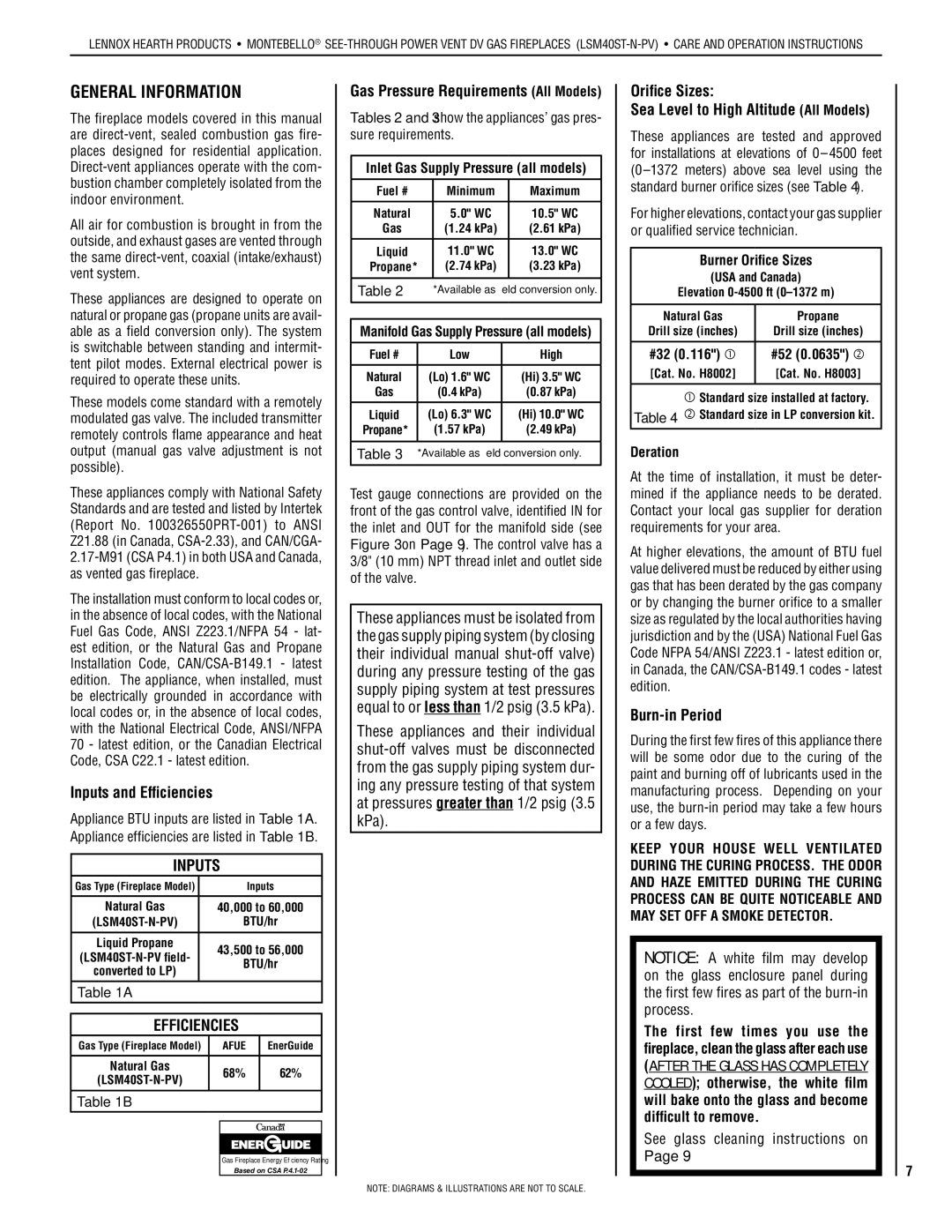

In terms of performance, this gas fireplace utilizes the latest innovations in venting technology, offering versatility for installation. The direct vent system draws air from outside for combustion, ensuring optimal efficiency while maintaining indoor air quality. This feature allows homeowners to enjoy a cozy fire without worrying about the impact on the surrounding environment.

The LSM40ST-N-PV is equipped with a powerful, multi-functional remote control, enabling users to adjust the flames, heat settings, and even the blower fan from the comfort of their couch. This user-friendly control system enhances the overall convenience and allows for a customized heating experience.

Another significant characteristic of the Lennox Hearth LSM40ST-N-PV is its high-efficiency rating. With minimal heat loss and effective distribution, this fireplace quickly warms up spaces, offering comfort even during the coldest months. The model also features an adjustable flame height, allowing homeowners to create the perfect ambiance, whether for a cozy evening or a festive gathering.

In terms of aesthetics, the fireplace can be fitted with a variety of decorative media options, such as glass, logs, or stones, catering to individual tastes and enhancing the visual appeal. Additionally, the unit operates quietly, ensuring that the crackle of flames is the only sound heard, promoting a peaceful environment.

Durability is also a key attribute of the LSM40ST-N-PV. Constructed from high-quality materials, it's built to last while requiring minimal maintenance. Easy installation and clear documentation mean that homeowners can enjoy their new fireplace with ease.

In summary, the Lennox Hearth LSM40ST-N-PV gas fireplace offers modern design, advanced technologies, and exceptional efficiency, making it a perfect addition to any home looking to elevate its comfort and style.