Packing Replacement Procedures

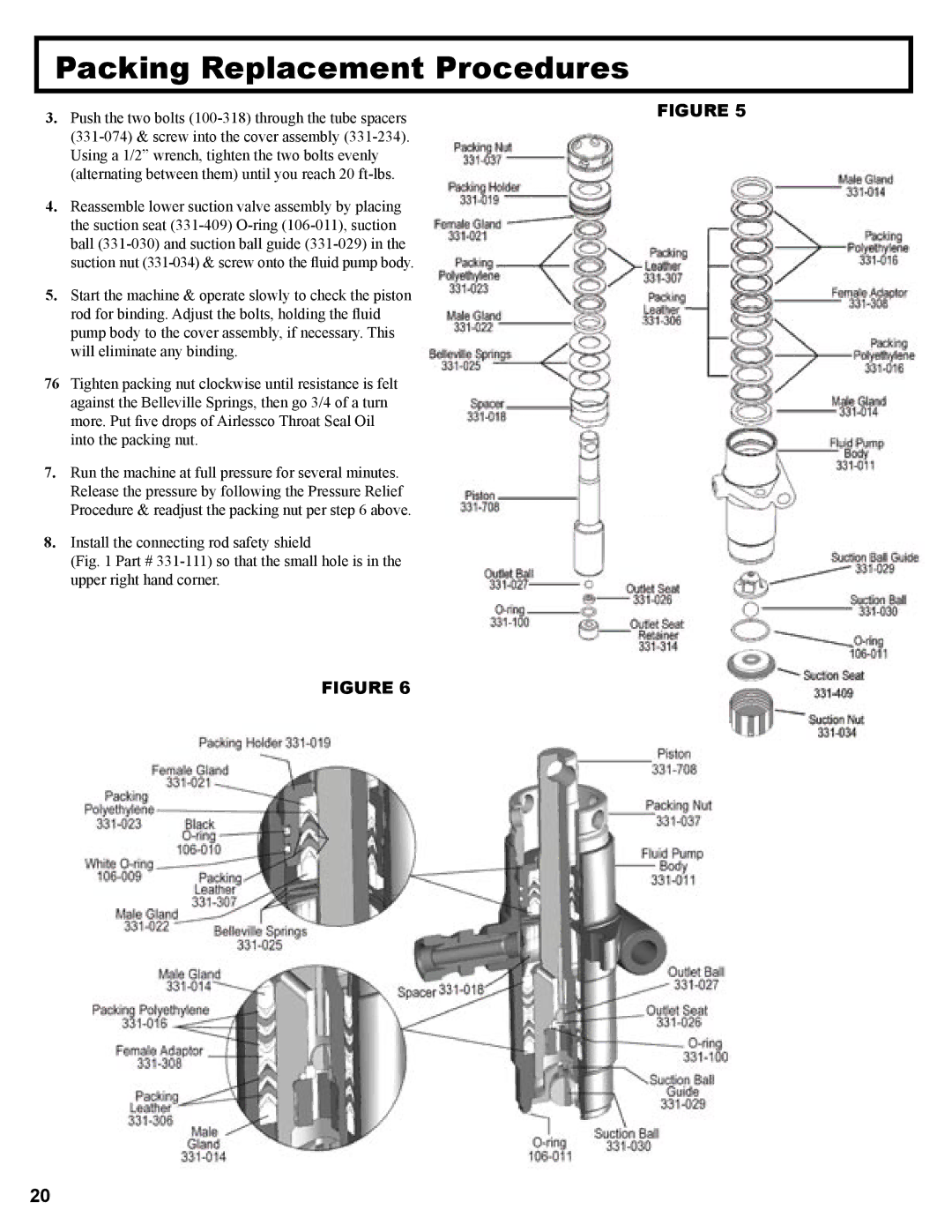

3. | Push the two bolts | FIGURE 5 |

|

4.Reassemble lower suction valve assembly by placing the suction seat

5.Start the machine & operate slowly to check the piston rod for binding. Adjust the bolts, holding the fluid pump body to the cover assembly, if necessary. This will eliminate any binding.

76Tighten packing nut clockwise until resistance is felt against the Belleville Springs, then go 3/4 of a turn more. Put five drops of Airlessco Throat Seal Oil into the packing nut.

7.Run the machine at full pressure for several minutes. Release the pressure by following the Pressure Relief Procedure & readjust the packing nut per step 6 above.

8.Install the connecting rod safety shield

(Fig. 1 Part # 331-111) so that the small hole is in the upper right hand corner.

FIGURE 6

20