Electrical Control Board Replacement

1.Remove electrical cover.

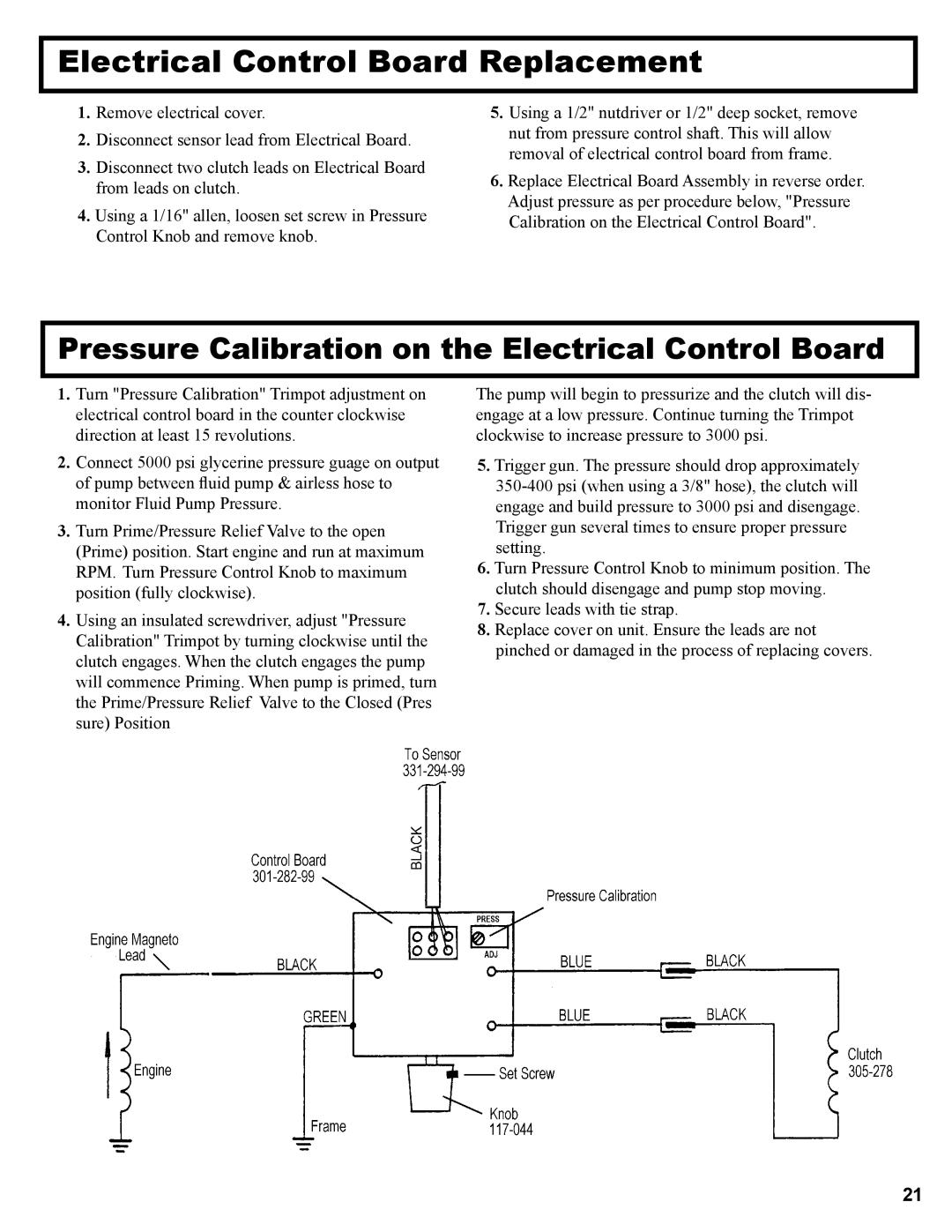

2.Disconnect sensor lead from Electrical Board.

3.Disconnect two clutch leads on Electrical Board from leads on clutch.

4.Using a 1/16" allen, loosen set screw in Pressure Control Knob and remove knob.

5.Using a 1/2" nutdriver or 1/2" deep socket, remove nut from pressure control shaft. This will allow removal of electrical control board from frame.

6.Replace Electrical Board Assembly in reverse order. Adjust pressure as per procedure below, "Pressure Calibration on the Electrical Control Board".

Pressure Calibration on the Electrical Control Board

1.Turn "Pressure Calibration" Trimpot adjustment on electrical control board in the counter clockwise direction at least 15 revolutions.

2.Connect 5000 psi glycerine pressure guage on output of pump between fluid pump & airless hose to monitor Fluid Pump Pressure.

3.Turn Prime/Pressure Relief Valve to the open (Prime) position. Start engine and run at maximum RPM. Turn Pressure Control Knob to maximum position (fully clockwise).

4.Using an insulated screwdriver, adjust "Pressure Calibration" Trimpot by turning clockwise until the clutch engages. When the clutch engages the pump will commence Priming. When pump is primed, turn the Prime/Pressure Relief Valve to the Closed (Pres sure) Position

The pump will begin to pressurize and the clutch will dis- engage at a low pressure. Continue turning the Trimpot clockwise to increase pressure to 3000 psi.

5.Trigger gun. The pressure should drop approximately

6.Turn Pressure Control Knob to minimum position. The clutch should disengage and pump stop moving.

7.Secure leads with tie strap.

8.Replace cover on unit. Ensure the leads are not pinched or damaged in the process of replacing covers.

21