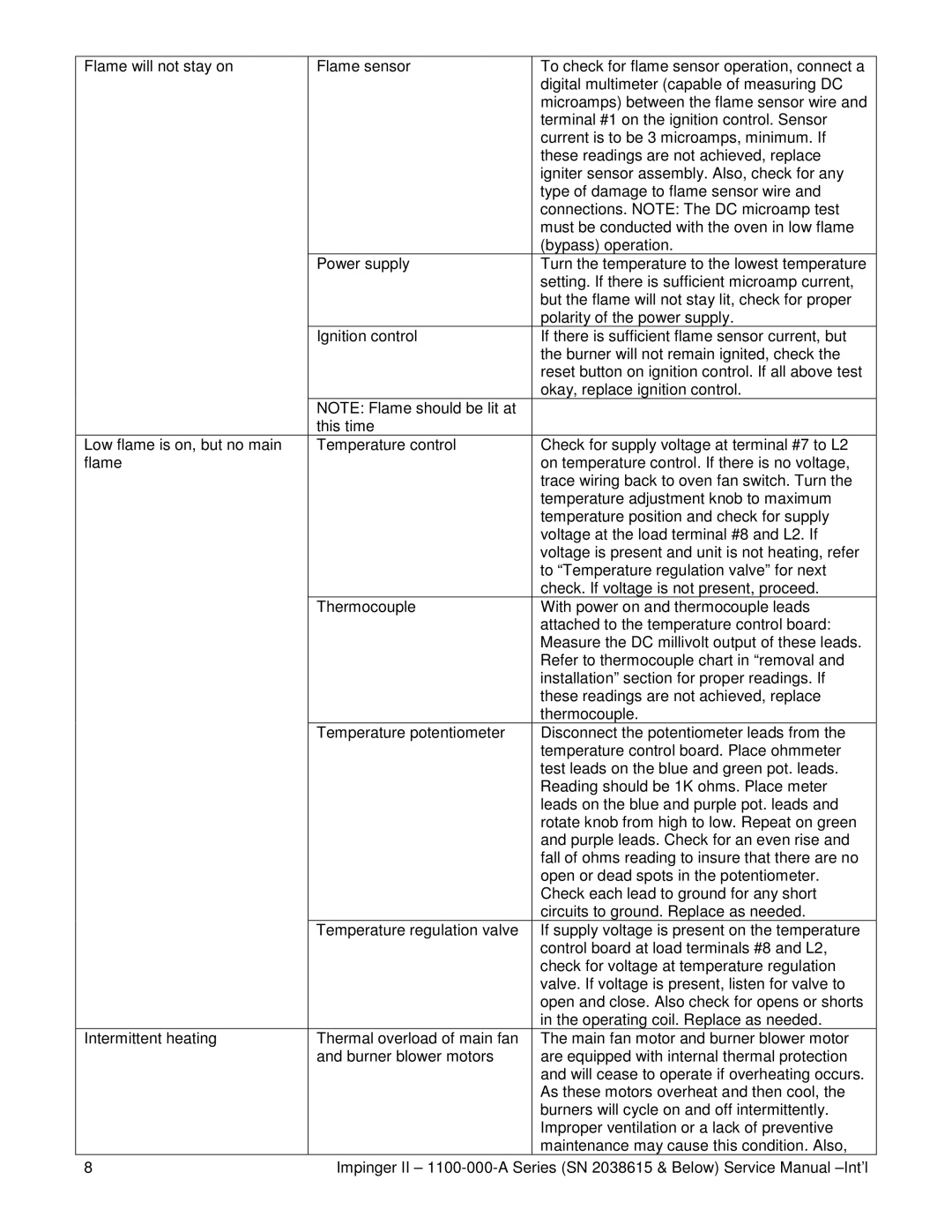

Flame will not stay on | Flame sensor | To check for flame sensor operation, connect a |

|

| digital multimeter (capable of measuring DC |

|

| microamps) between the flame sensor wire and |

|

| terminal #1 on the ignition control. Sensor |

|

| current is to be 3 microamps, minimum. If |

|

| these readings are not achieved, replace |

|

| igniter sensor assembly. Also, check for any |

|

| type of damage to flame sensor wire and |

|

| connections. NOTE: The DC microamp test |

|

| must be conducted with the oven in low flame |

|

| (bypass) operation. |

| Power supply | Turn the temperature to the lowest temperature |

|

| setting. If there is sufficient microamp current, |

|

| but the flame will not stay lit, check for proper |

|

| polarity of the power supply. |

| Ignition control | If there is sufficient flame sensor current, but |

|

| the burner will not remain ignited, check the |

|

| reset button on ignition control. If all above test |

|

| okay, replace ignition control. |

| NOTE: Flame should be lit at |

|

| this time |

|

Low flame is on, but no main | Temperature control | Check for supply voltage at terminal #7 to L2 |

flame |

| on temperature control. If there is no voltage, |

|

| trace wiring back to oven fan switch. Turn the |

|

| temperature adjustment knob to maximum |

|

| temperature position and check for supply |

|

| voltage at the load terminal #8 and L2. If |

|

| voltage is present and unit is not heating, refer |

|

| to “Temperature regulation valve” for next |

|

| check. If voltage is not present, proceed. |

| Thermocouple | With power on and thermocouple leads |

|

| attached to the temperature control board: |

|

| Measure the DC millivolt output of these leads. |

|

| Refer to thermocouple chart in “removal and |

|

| installation” section for proper readings. If |

|

| these readings are not achieved, replace |

|

| thermocouple. |

| Temperature potentiometer | Disconnect the potentiometer leads from the |

|

| temperature control board. Place ohmmeter |

|

| test leads on the blue and green pot. leads. |

|

| Reading should be 1K ohms. Place meter |

|

| leads on the blue and purple pot. leads and |

|

| rotate knob from high to low. Repeat on green |

|

| and purple leads. Check for an even rise and |

|

| fall of ohms reading to insure that there are no |

|

| open or dead spots in the potentiometer. |

|

| Check each lead to ground for any short |

|

| circuits to ground. Replace as needed. |

| Temperature regulation valve | If supply voltage is present on the temperature |

|

| control board at load terminals #8 and L2, |

|

| check for voltage at temperature regulation |

|

| valve. If voltage is present, listen for valve to |

|

| open and close. Also check for opens or shorts |

|

| in the operating coil. Replace as needed. |

Intermittent heating | Thermal overload of main fan | The main fan motor and burner blower motor |

| and burner blower motors | are equipped with internal thermal protection |

|

| and will cease to operate if overheating occurs. |

|

| As these motors overheat and then cool, the |

|

| burners will cycle on and off intermittently. |

|

| Improper ventilation or a lack of preventive |

|

| maintenance may cause this condition. Also, |

8 | Impinger II – | |