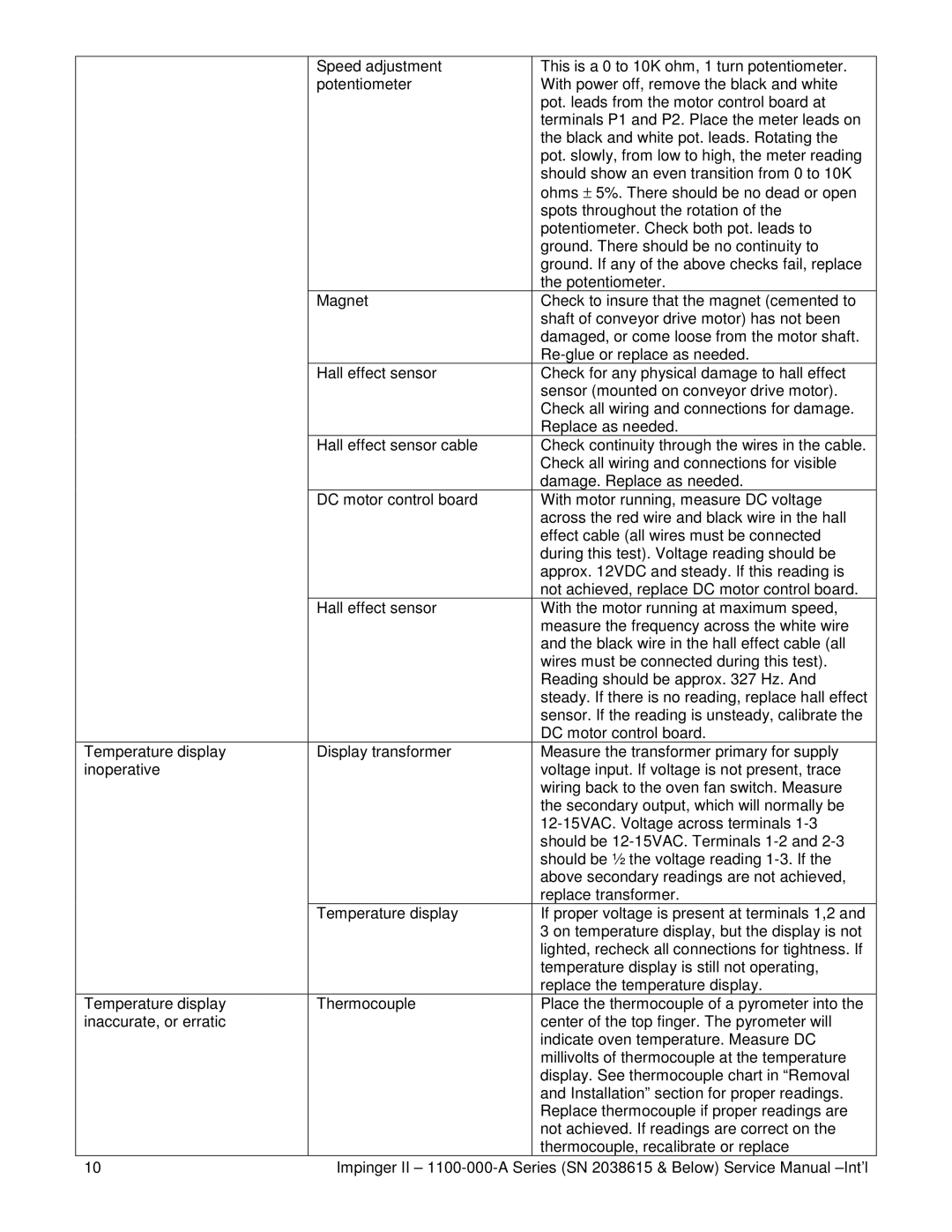

| Speed adjustment | This is a 0 to 10K ohm, 1 turn potentiometer. |

| potentiometer | With power off, remove the black and white |

|

| pot. leads from the motor control board at |

|

| terminals P1 and P2. Place the meter leads on |

|

| the black and white pot. leads. Rotating the |

|

| pot. slowly, from low to high, the meter reading |

|

| should show an even transition from 0 to 10K |

|

| ohms ± 5%. There should be no dead or open |

|

| spots throughout the rotation of the |

|

| potentiometer. Check both pot. leads to |

|

| ground. There should be no continuity to |

|

| ground. If any of the above checks fail, replace |

|

| the potentiometer. |

| Magnet | Check to insure that the magnet (cemented to |

|

| shaft of conveyor drive motor) has not been |

|

| damaged, or come loose from the motor shaft. |

|

| |

| Hall effect sensor | Check for any physical damage to hall effect |

|

| sensor (mounted on conveyor drive motor). |

|

| Check all wiring and connections for damage. |

|

| Replace as needed. |

| Hall effect sensor cable | Check continuity through the wires in the cable. |

|

| Check all wiring and connections for visible |

|

| damage. Replace as needed. |

| DC motor control board | With motor running, measure DC voltage |

|

| across the red wire and black wire in the hall |

|

| effect cable (all wires must be connected |

|

| during this test). Voltage reading should be |

|

| approx. 12VDC and steady. If this reading is |

|

| not achieved, replace DC motor control board. |

| Hall effect sensor | With the motor running at maximum speed, |

|

| measure the frequency across the white wire |

|

| and the black wire in the hall effect cable (all |

|

| wires must be connected during this test). |

|

| Reading should be approx. 327 Hz. And |

|

| steady. If there is no reading, replace hall effect |

|

| sensor. If the reading is unsteady, calibrate the |

|

| DC motor control board. |

Temperature display | Display transformer | Measure the transformer primary for supply |

inoperative |

| voltage input. If voltage is not present, trace |

|

| wiring back to the oven fan switch. Measure |

|

| the secondary output, which will normally be |

|

| |

|

| should be |

|

| should be ½ the voltage reading |

|

| above secondary readings are not achieved, |

|

| replace transformer. |

| Temperature display | If proper voltage is present at terminals 1,2 and |

|

| 3 on temperature display, but the display is not |

|

| lighted, recheck all connections for tightness. If |

|

| temperature display is still not operating, |

|

| replace the temperature display. |

Temperature display | Thermocouple | Place the thermocouple of a pyrometer into the |

inaccurate, or erratic |

| center of the top finger. The pyrometer will |

|

| indicate oven temperature. Measure DC |

|

| millivolts of thermocouple at the temperature |

|

| display. See thermocouple chart in “Removal |

|

| and Installation” section for proper readings. |

|

| Replace thermocouple if proper readings are |

|

| not achieved. If readings are correct on the |

|

| thermocouple, recalibrate or replace |

10 | Impinger II – |