INSTALLATION |

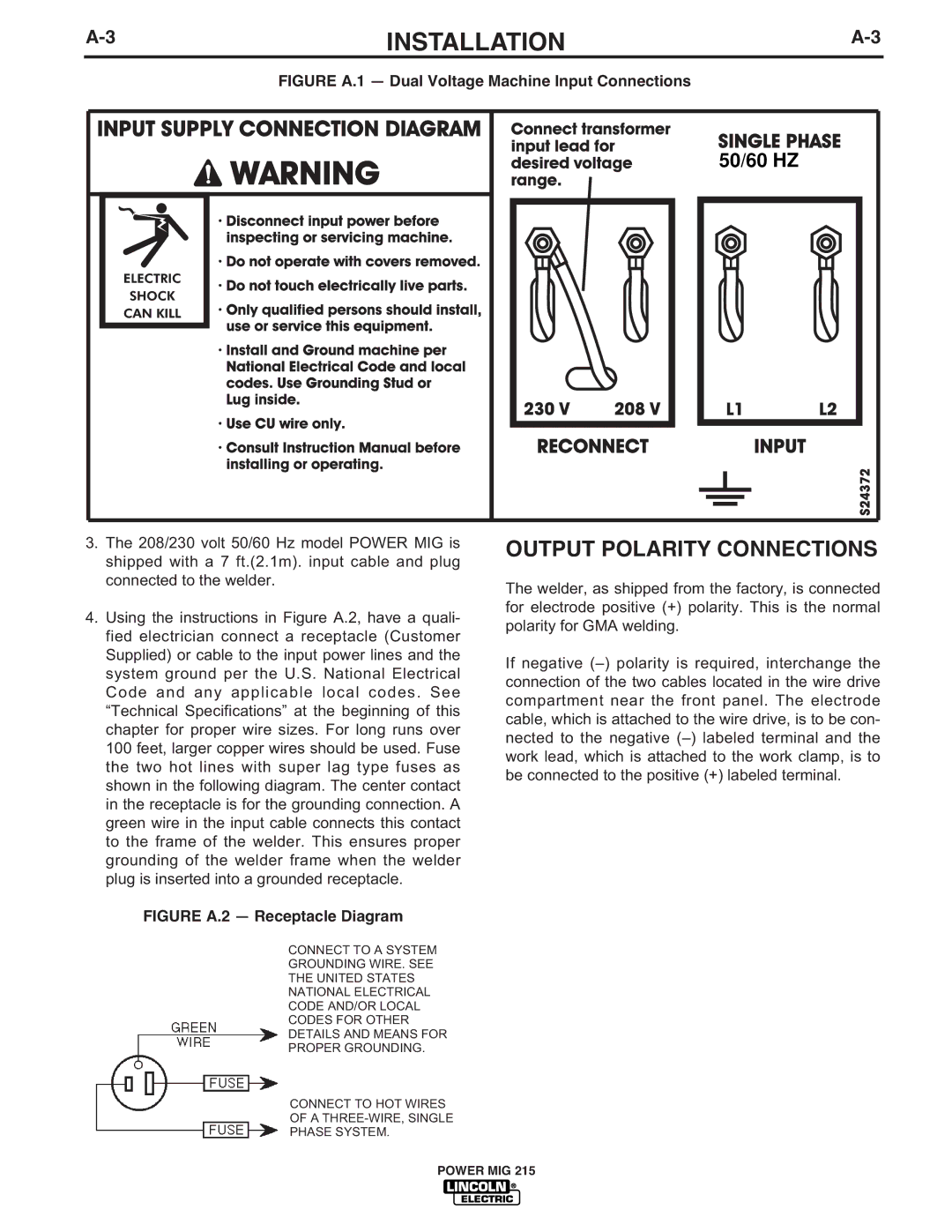

FIGURE A.1 — Dual Voltage Machine Input Connections

50/60 HZ |

3.The 208/230 volt 50/60 Hz model POWER MIG is shipped with a 7 ft.(2.1m). input cable and plug connected to the welder.

4.Using the instructions in Figure A.2, have a quali- fied electrician connect a receptacle (Customer Supplied) or cable to the input power lines and the system ground per the U.S. National Electrical Code and any applicable local codes. See “Technical Specifications” at the beginning of this chapter for proper wire sizes. For long runs over 100 feet, larger copper wires should be used. Fuse the two hot lines with super lag type fuses as shown in the following diagram. The center contact in the receptacle is for the grounding connection. A green wire in the input cable connects this contact to the frame of the welder. This ensures proper grounding of the welder frame when the welder plug is inserted into a grounded receptacle.

OUTPUT POLARITY CONNECTIONS

The welder, as shipped from the factory, is connected for electrode positive (+) polarity. This is the normal polarity for GMA welding.

If negative

FIGURE A.2 — Receptacle Diagram

CONNECT TO A SYSTEM

GROUNDING WIRE. SEE

THE UNITED STATES

NATIONAL ELECTRICAL

CODE AND/OR LOCAL

CODES FOR OTHER

DETAILS AND MEANS FOR

PROPER GROUNDING.

CONNECT TO HOT WIRES

OF A

PHASE SYSTEM.

POWER MIG 215