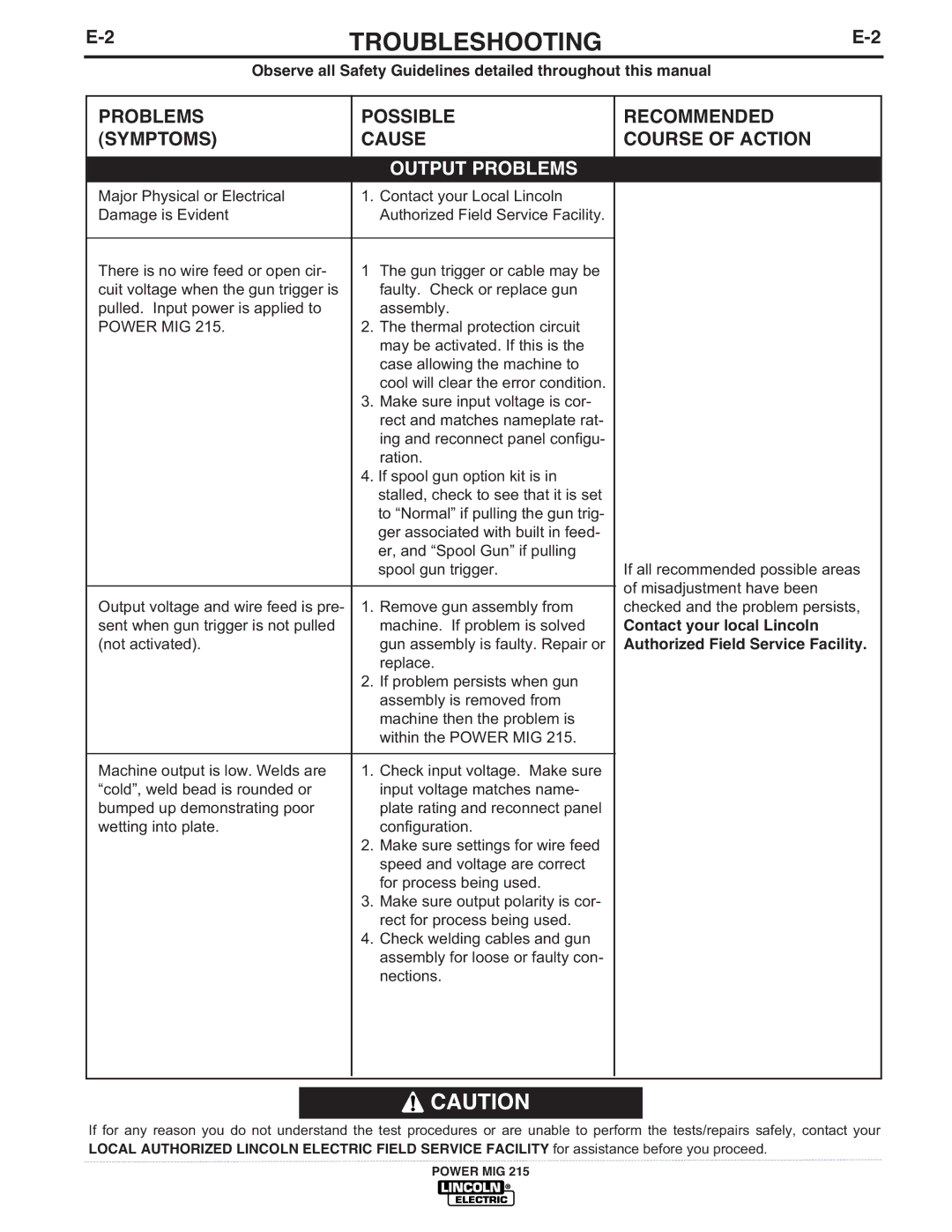

TROUBLESHOOTING | ||

| Observe all Safety Guidelines detailed throughout this manual |

|

|

|

|

|

|

|

|

| PROBLEMS |

|

| POSSIBLE |

| |

| (SYMPTOMS) |

|

| CAUSE |

| |

|

|

|

|

| OUTPUT PROBLEMS |

|

| Major Physical or Electrical |

|

| 1. | Contact your Local Lincoln |

|

| Damage is Evident |

|

|

| Authorized Field Service Facility. |

|

|

|

|

|

|

|

|

| There is no wire feed or open cir- |

|

| 1 | The gun trigger or cable may be |

|

| cuit voltage when the gun trigger is |

|

|

| faulty. Check or replace gun |

|

| pulled. Input power is applied to |

|

|

| assembly. |

|

| POWER MIG 215. |

|

| 2. | The thermal protection circuit |

|

|

|

|

|

| may be activated. If this is the |

|

|

|

|

|

| case allowing the machine to |

|

|

|

|

|

| cool will clear the error condition. |

|

|

|

|

| 3. | Make sure input voltage is cor- |

|

|

|

|

|

| rect and matches nameplate rat- |

|

|

|

|

|

| ing and reconnect panel configu- |

|

|

|

|

|

| ration. |

|

|

|

|

| 4. | If spool gun option kit is in |

|

|

|

|

|

| stalled, check to see that it is set |

|

|

|

|

|

| to “Normal” if pulling the gun trig- |

|

|

|

|

|

| ger associated with built in feed- |

|

|

|

|

|

| er, and “Spool Gun” if pulling |

|

|

|

|

|

| spool gun trigger. |

|

|

|

|

|

|

|

|

| Output voltage and wire feed is pre- |

|

| 1. | Remove gun assembly from |

|

| sent when gun trigger is not pulled |

|

|

| machine. If problem is solved |

|

| (not activated). |

|

|

| gun assembly is faulty. Repair or |

|

|

|

|

|

| replace. |

|

|

|

|

| 2. | If problem persists when gun |

|

|

|

|

|

| assembly is removed from |

|

|

|

|

|

| machine then the problem is |

|

|

|

|

|

| within the POWER MIG 215. |

|

|

|

|

|

|

|

|

| Machine output is low. Welds are |

|

| 1. | Check input voltage. Make sure |

|

| “cold”, weld bead is rounded or |

|

|

| input voltage matches name- |

|

| bumped up demonstrating poor |

|

|

| plate rating and reconnect panel |

|

| wetting into plate. |

|

|

| configuration. |

|

|

|

|

| 2. | Make sure settings for wire feed |

|

|

|

|

|

| speed and voltage are correct |

|

|

|

|

|

| for process being used. |

|

|

|

|

| 3. | Make sure output polarity is cor- |

|

|

|

|

|

| rect for process being used. |

|

|

|

|

| 4. | Check welding cables and gun |

|

|

|

|

|

| assembly for loose or faulty con- |

|

|

|

|

|

| nections. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RECOMMENDED COURSE OF ACTION

If all recommended possible areas of misadjustment have been checked and the problem persists,

Contact your local Lincoln Authorized Field Service Facility.

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

LOCAL AUTHORIZED LINCOLN ELECTRIC FIELD SERVICE FACILITY for assistance before you proceed.

POWER MIG 215