W A V E F O R M C O N T R O L T E C H N O L O G Y T M

APPLICATION

Tandem MIG | 14/16 |

|

|

Lincoln Welding Systems Featuring Tandem MIG

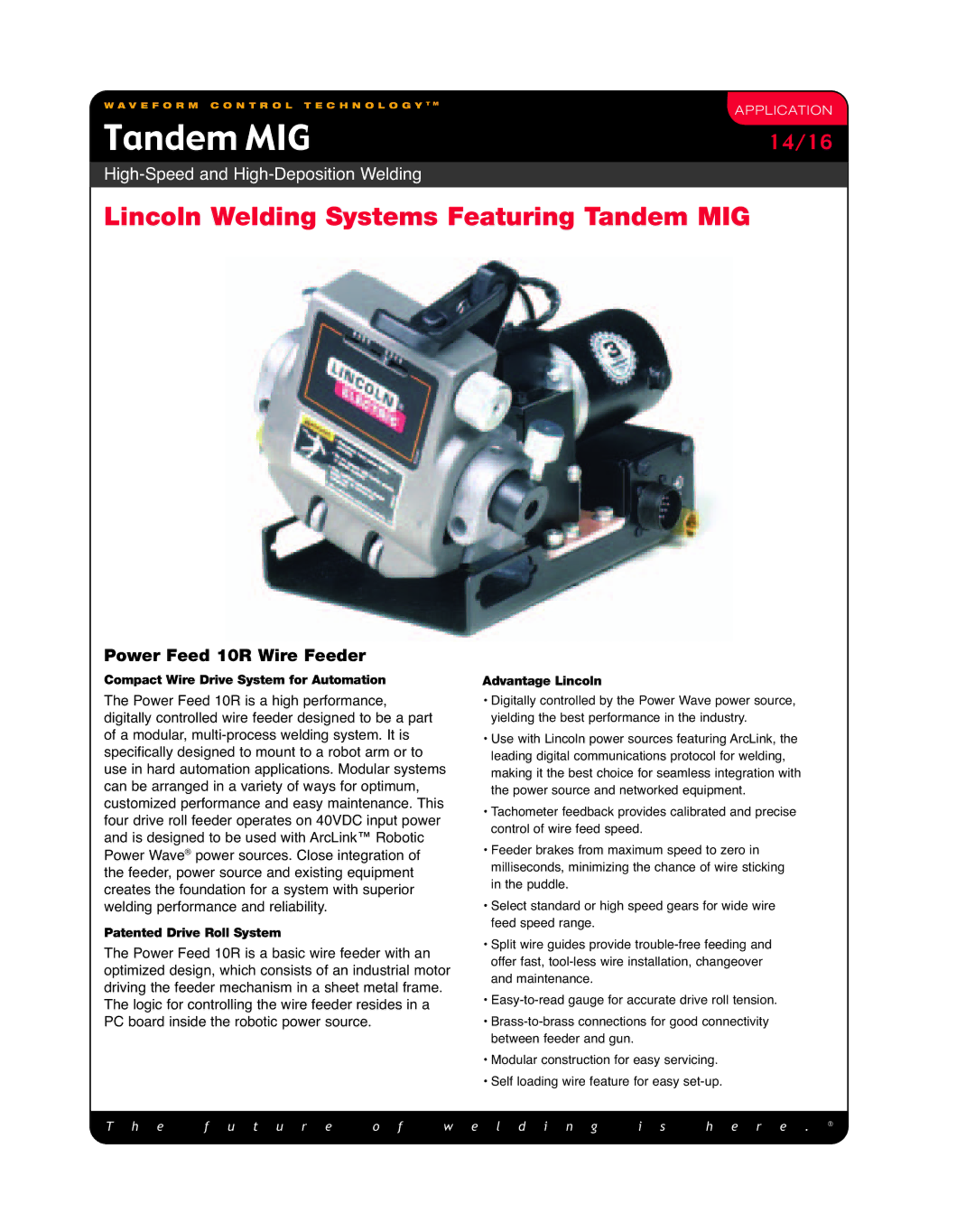

Power Feed 10R Wire Feeder

Compact Wire Drive System for Automation

The Power Feed 10R is a high performance, digitally controlled wire feeder designed to be a part of a modular,

Patented Drive Roll System

The Power Feed 10R is a basic wire feeder with an optimized design, which consists of an industrial motor driving the feeder mechanism in a sheet metal frame. The logic for controlling the wire feeder resides in a PC board inside the robotic power source.

Advantage Lincoln

•Digitally controlled by the Power Wave power source, yielding the best performance in the industry.

•Use with Lincoln power sources featuring ArcLink, the leading digital communications protocol for welding, making it the best choice for seamless integration with the power source and networked equipment.

•Tachometer feedback provides calibrated and precise control of wire feed speed.

•Feeder brakes from maximum speed to zero in milliseconds, minimizing the chance of wire sticking in the puddle.

•Select standard or high speed gears for wide wire feed speed range.

•Split wire guides provide

•

•

•Modular construction for easy servicing.

•Self loading wire feature for easy

T h e | f u t u r e | o f | w e l d i n g | i s | h e r e . | ® |

| ||||||

|

|

|

|

|

|

|