W A V E F O R M C O N T R O L T E C H N O L O G Y T M

APPLICATION

Tandem MIG | 6/16 |

|

|

Comparing High-Speed Tandem MIG

To Single Wire GMAW Processes

Better Weld Metal Follow Characteristics:

Problem - Single Wire GMAW

As higher travel speeds are explored with conventional single solid and metal cored wire GMAW processes one of the factors that limits obtainable travel speeds is a phenomenon referred to as “bead humping” or lack of follow. The lack of follow occurs as a number of physical metal flow requirements break down. The coalescent properties of the weld pool are not strong enough to pull the puddle along while, at the same time, the higher travel speeds limit the heating of the plate that would normally allow the weld pool to wet or flow along the weld bead edges.

Solution - Tandem MIG

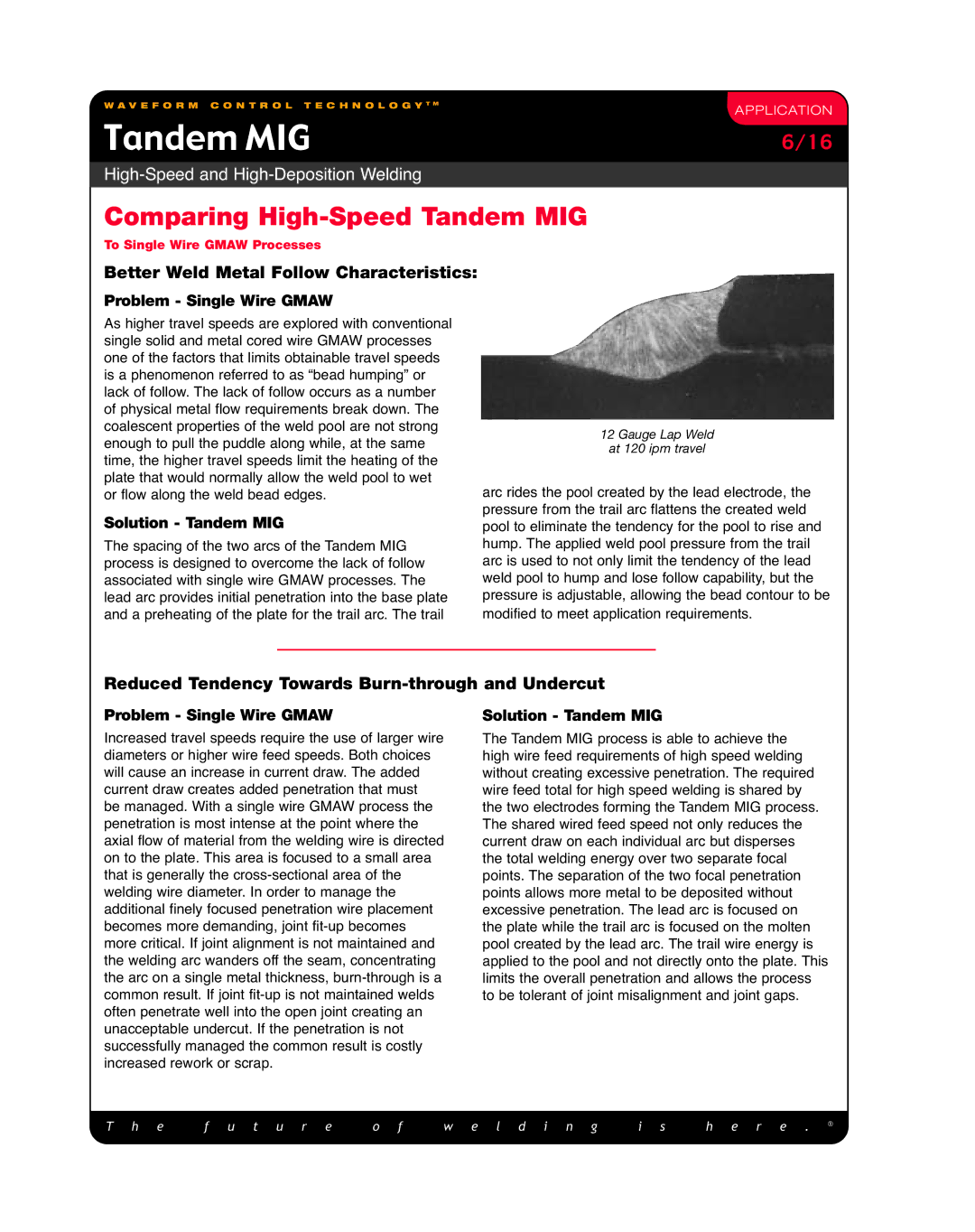

The spacing of the two arcs of the Tandem MIG process is designed to overcome the lack of follow associated with single wire GMAW processes. The lead arc provides initial penetration into the base plate and a preheating of the plate for the trail arc. The trail

12 Gauge Lap Weld

at 120 ipm travel

arc rides the pool created by the lead electrode, the pressure from the trail arc flattens the created weld pool to eliminate the tendency for the pool to rise and hump. The applied weld pool pressure from the trail arc is used to not only limit the tendency of the lead weld pool to hump and lose follow capability, but the pressure is adjustable, allowing the bead contour to be modified to meet application requirements.

Reduced Tendency Towards Burn-through and Undercut

Problem - Single Wire GMAW

Increased travel speeds require the use of larger wire diameters or higher wire feed speeds. Both choices will cause an increase in current draw. The added current draw creates added penetration that must be managed. With a single wire GMAW process the penetration is most intense at the point where the axial flow of material from the welding wire is directed on to the plate. This area is focused to a small area that is generally the

Solution - Tandem MIG

The Tandem MIG process is able to achieve the high wire feed requirements of high speed welding without creating excessive penetration. The required wire feed total for high speed welding is shared by the two electrodes forming the Tandem MIG process. The shared wired feed speed not only reduces the current draw on each individual arc but disperses the total welding energy over two separate focal points. The separation of the two focal penetration points allows more metal to be deposited without excessive penetration. The lead arc is focused on the plate while the trail arc is focused on the molten pool created by the lead arc. The trail wire energy is applied to the pool and not directly onto the plate. This limits the overall penetration and allows the process to be tolerant of joint misalignment and joint gaps.

T h e | f u t u r e | o f | w e l d i n g | i s | h e r e . | ® |

| ||||||

|

|

|

|

|

|

|