W A V E F O R M C O N T R O L T E C H N O L O G Y T M

Tandem MIG

High-Speed and High-Deposition Welding

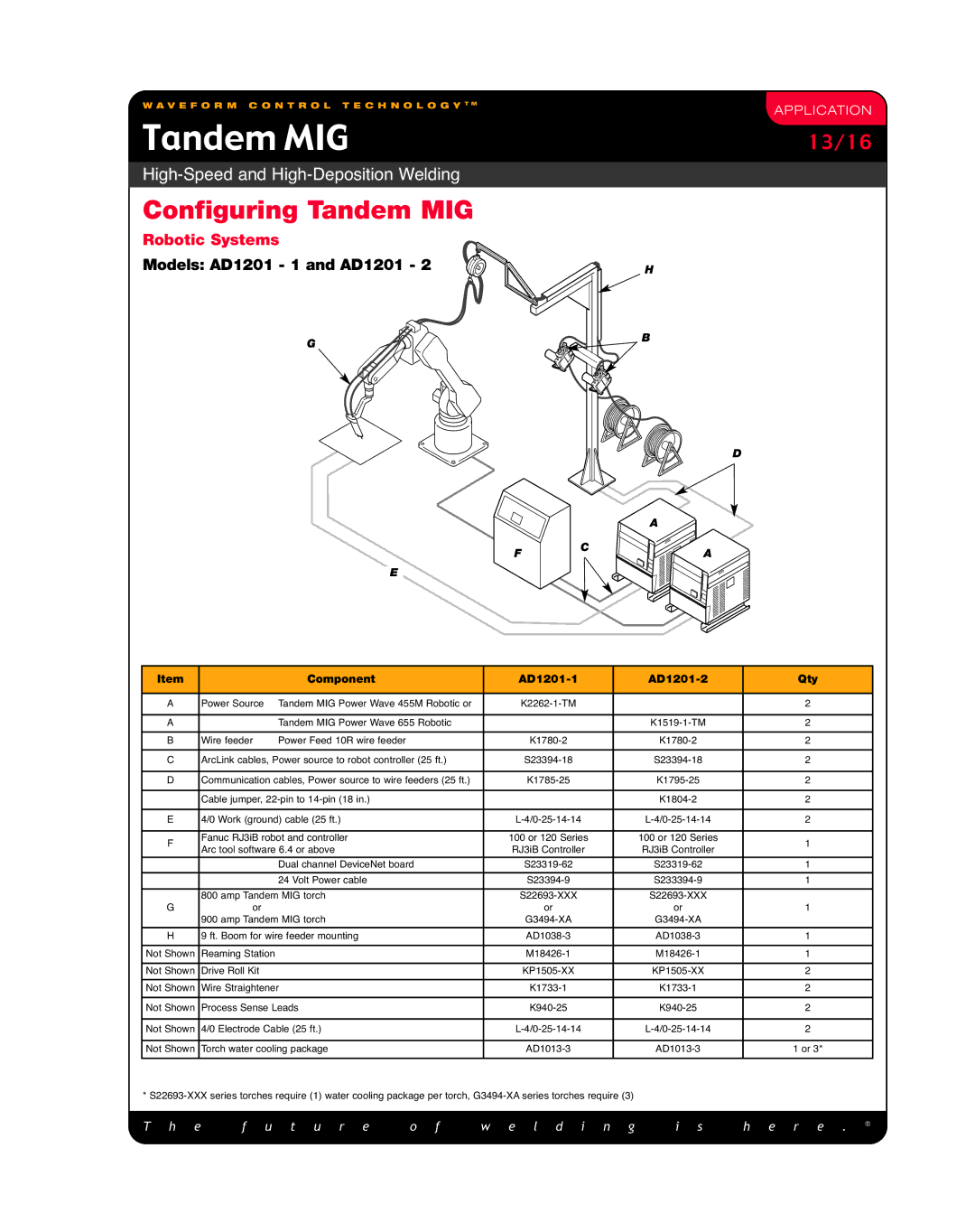

Configuring Tandem MIG

Robotic Systems

Models: AD1201 - 1 and AD1201 - 2

G

F

E

APPLICATION

13/16

H

B

D

| A |

C | A |

|

Item |

| Component |

|

| Qty | |

|

|

|

|

|

| |

A | Power Source | Tandem MIG Power Wave 455M Robotic or |

| 2 | ||

|

|

|

|

|

| |

A |

| Tandem MIG Power Wave 655 Robotic |

| 2 | ||

B | Wire feeder | Power Feed 10R wire feeder | 2 | |||

C | ArcLink cables, Power source to robot controller (25 ft.) | 2 | ||||

|

|

|

|

| ||

D | Communication cables, Power source to wire feeders (25 ft.) | 2 | ||||

| Cable jumper, |

| 2 | |||

|

|

|

|

| ||

E | 4/0 Work (ground) cable (25 ft.) | 2 | ||||

|

|

|

|

| ||

F | Fanuc RJ3iB robot and controller | 100 or 120 Series | 100 or 120 Series | 1 | ||

Arc tool software 6.4 or above | RJ3iB Controller | RJ3iB Controller | ||||

|

| |||||

|

| Dual channel DeviceNet board | 1 | |||

|

| 24 Volt Power cable | 1 | |||

| 800 amp Tandem MIG torch |

| ||||

G | or |

| or | or | 1 | |

| 900 amp Tandem MIG torch |

| ||||

H | 9 ft. Boom for wire feeder mounting | 1 | ||||

Not Shown | Reaming Station |

| 1 | |||

Not Shown | Drive Roll Kit |

| 2 | |||

Not Shown | Wire Straightener | 2 | ||||

Not Shown | Process Sense Leads | 2 | ||||

|

|

|

|

| ||

Not Shown | 4/0 Electrode Cable (25 ft.) | 2 | ||||

|

|

|

|

| ||

Not Shown | Torch water cooling package | 1 or 3* | ||||

*

T h e | f u t u r e | o f | w e l d i n g | i s | h e r e . | ® |

| ||||||

|

|

|

|

|

|

|