OPERATION | ||

|

|

|

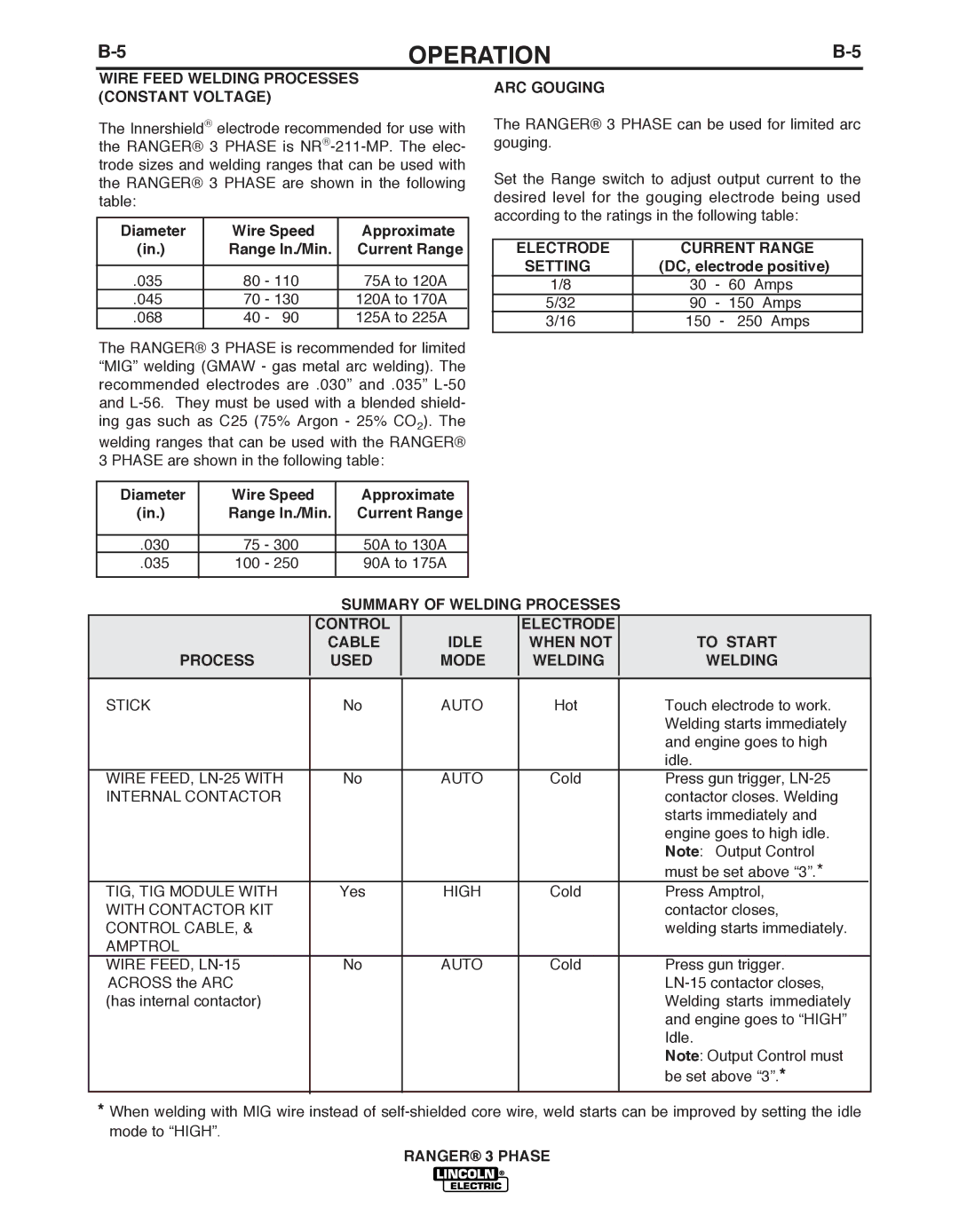

WIRE FEED WELDING PROCESSES (CONSTANT VOLTAGE)

The Innershield® electrode recommended for use with the RANGER® 3 PHASE is

Diameter | Wire Speed | Approximate | |

(in.) | Range In./Min. | Current Range | |

|

|

|

|

.035 | 80 | - 110 | 75A to 120A |

.045 | 70 | - 130 | 120A to 170A |

.068 | 40 | - 90 | 125A to 225A |

The RANGER® 3 PHASE is recommended for limited “MIG” welding (GMAW - gas metal arc welding). The recommended electrodes are .030” and .035”

3 PHASE are shown in the following table:

Diameter | Wire Speed | Approximate | |

(in.) | Range In./Min. | Current Range | |

|

|

|

|

.030 | 75 | - 300 | 50A to 130A |

.035 | 100 | - 250 | 90A to 175A |

|

|

|

|

ARC GOUGING

The RANGER® 3 PHASE can be used for limited arc gouging.

Set the Range switch to adjust output current to the desired level for the gouging electrode being used according to the ratings in the following table:

ELECTRODE | CURRENT RANGE | ||

SETTING | (DC, electrode positive) | ||

1/8 | 30 | - | 60 Amps |

5/32 | 90 | - | 150 Amps |

3/16 | 150 - 250 Amps | ||

|

|

|

|

SUMMARY OF WELDING PROCESSES

| CONTROL |

| ELECTRODE |

|

| CAbLE | IDLE | WhEN NOT | TO START |

PROCESS | USED | MODE | WELDING | WELDING |

|

|

|

|

|

STICK | No | AUTO | Hot | Touch electrode to work. |

|

|

|

| Welding starts immediately |

|

|

|

| and engine goes to high |

|

|

|

| idle. |

WIRE FEED, | No | AUTO | Cold | Press gun trigger, |

INTERNAL CONTACTOR |

|

|

| contactor closes. Welding |

|

|

|

| starts immediately and |

|

|

|

| engine goes to high idle. |

|

|

|

| Note: Output Control |

|

|

|

| must be set above “3”.* |

TIG, TIG MODULE WITH | Yes | HIGH | Cold | Press Amptrol, |

WITH CONTACTOR KIT |

|

|

| contactor closes, |

CONTROL CABLE, & |

|

|

| welding starts immediately. |

AMPTROL |

|

|

|

|

WIRE FEED, | No | AUTO | Cold | Press gun trigger. |

ACROSS the ARC |

|

|

| |

(has internal contactor) |

|

|

| Welding starts immediately |

|

|

|

| and engine goes to “HIGH” |

|

|

|

| Idle. |

|

|

|

| Note: Output Control must |

|

|

|

| be set above “3”.* |

|

|

|

|

|

*When welding with MIG wire instead of

RANGER® 3 PhASE