| TROUBLESHOOTING |

| ||||

|

|

|

|

|

| |

|

|

| Observe all Safety Guidelines detailed throughout this manual |

|

| |

|

|

|

|

|

|

|

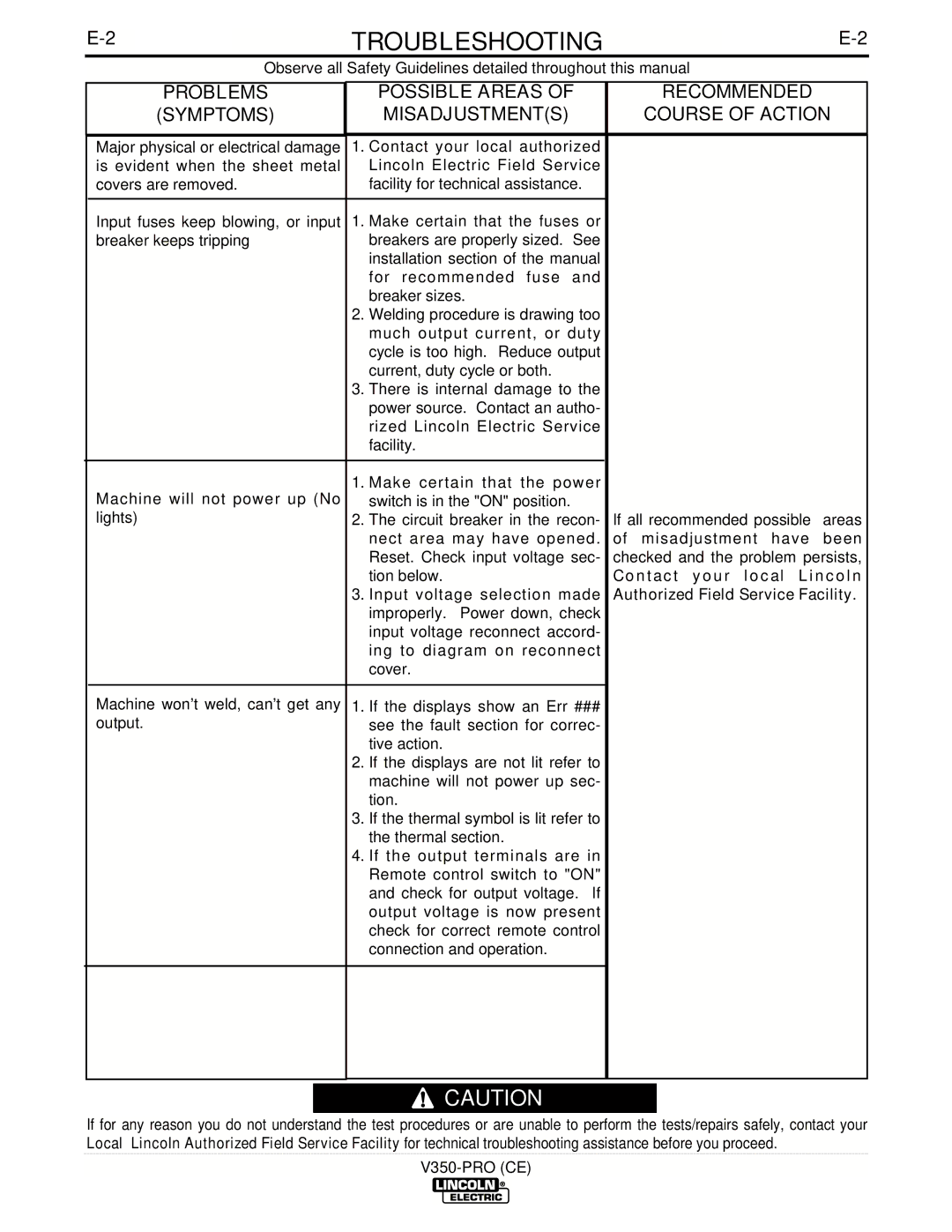

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

| Major physical or electrical damage | 1. | Contact your local authorized |

| is evident when the sheet metal |

| Lincoln Electric Field Service |

| covers are removed. |

| facility for technical assistance. |

| Input fuses keep blowing, or input | 1. | Make certain that the fuses or |

| breaker keeps tripping |

| breakers are properly sized. See |

|

|

| installation section of the manual |

|

|

| for recommended fuse and |

|

|

| breaker sizes. |

|

| 2. | Welding procedure is drawing too |

|

|

| much output current, or duty |

|

|

| cycle is too high. Reduce output |

|

|

| current, duty cycle or both. |

|

| 3. | There is internal damage to the |

|

|

| power source. Contact an autho- |

|

|

| rized Lincoln Electric Service |

|

|

| facility. |

| Machine will not power up (No | 1. Make certain that the power | |

|

| switch is in the "ON" position. | |

| lights) | 2. The circuit breaker in the recon- | |

|

|

| nect area may have opened. |

|

|

| Reset. Check input voltage sec- |

|

|

| tion below. |

|

| 3. | Input voltage selection made |

|

|

| improperly. Power down, check |

|

|

| input voltage reconnect accord- |

|

|

| ing to diagram on reconnect |

|

|

| cover. |

|

|

|

|

| Machine won’t weld, can’t get any | 1. | If the displays show an Err ### |

| output. |

| see the fault section for correc- |

|

|

| tive action. |

|

| 2. | If the displays are not lit refer to |

|

|

| machine will not power up sec- |

|

|

| tion. |

|

| 3. | If the thermal symbol is lit refer to |

|

|

| the thermal section. |

|

| 4. | If the output terminals are in |

|

|

| Remote control switch to "ON" |

|

|

| and check for output voltage. If |

|

|

| output voltage is now present |

|

|

| check for correct remote control |

|

|

| connection and operation. |

|

|

|

|

|

|

|

|

If all recommended possible areas of misadjustment have been checked and the problem persists,

Contact your local Lincoln Authorized Field Service Facility.

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.